Biaxially stretched polyester film

A biaxial stretching, polyester film technology, applied in polyurea/polyurethane coatings, electronic equipment, applications, etc., can solve the problems of penetration, low swelling effect, and insufficient adhesion of the easy-bonding layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

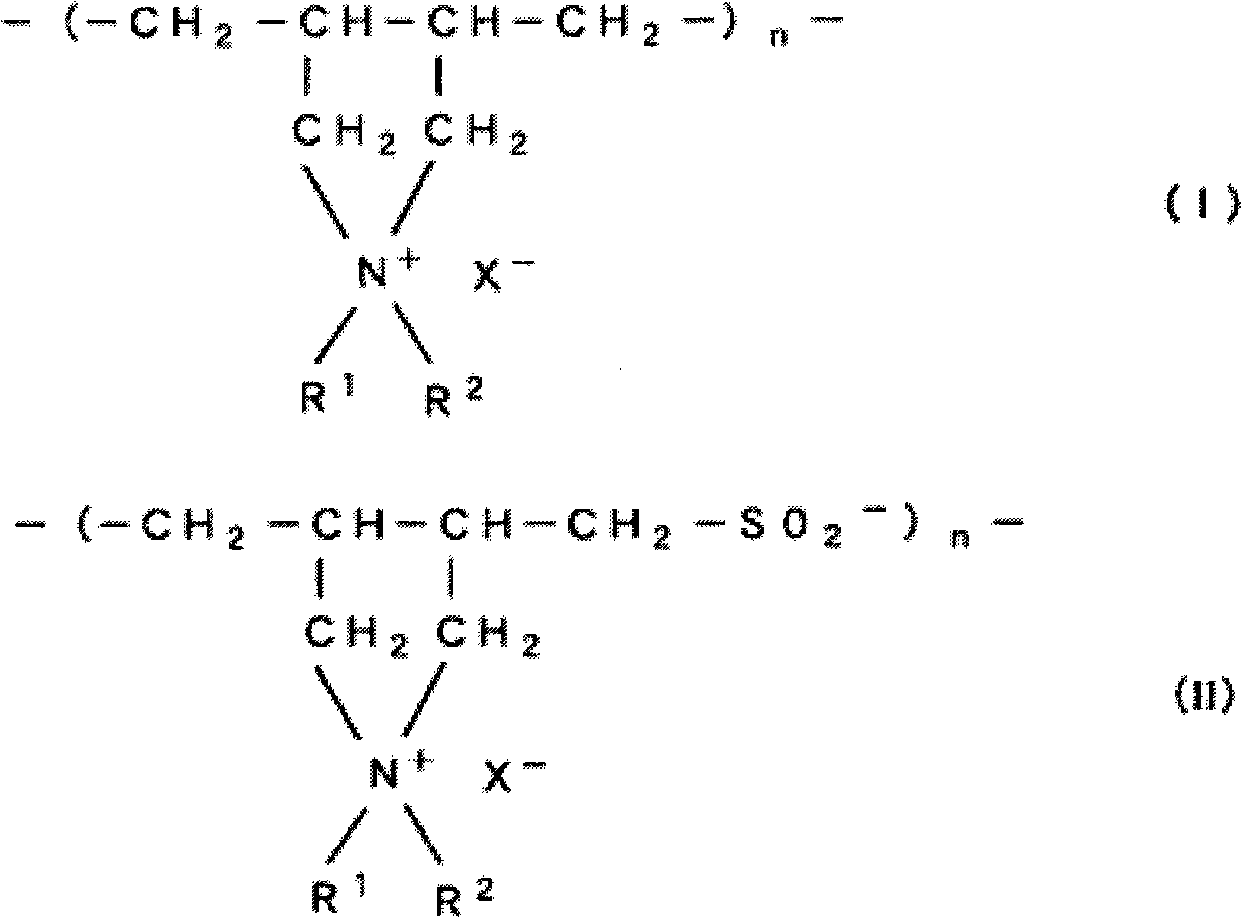

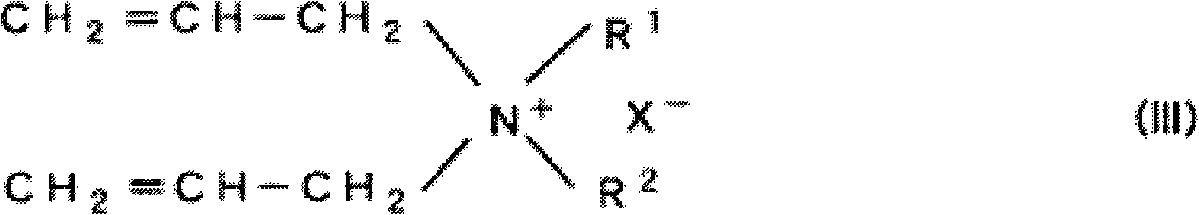

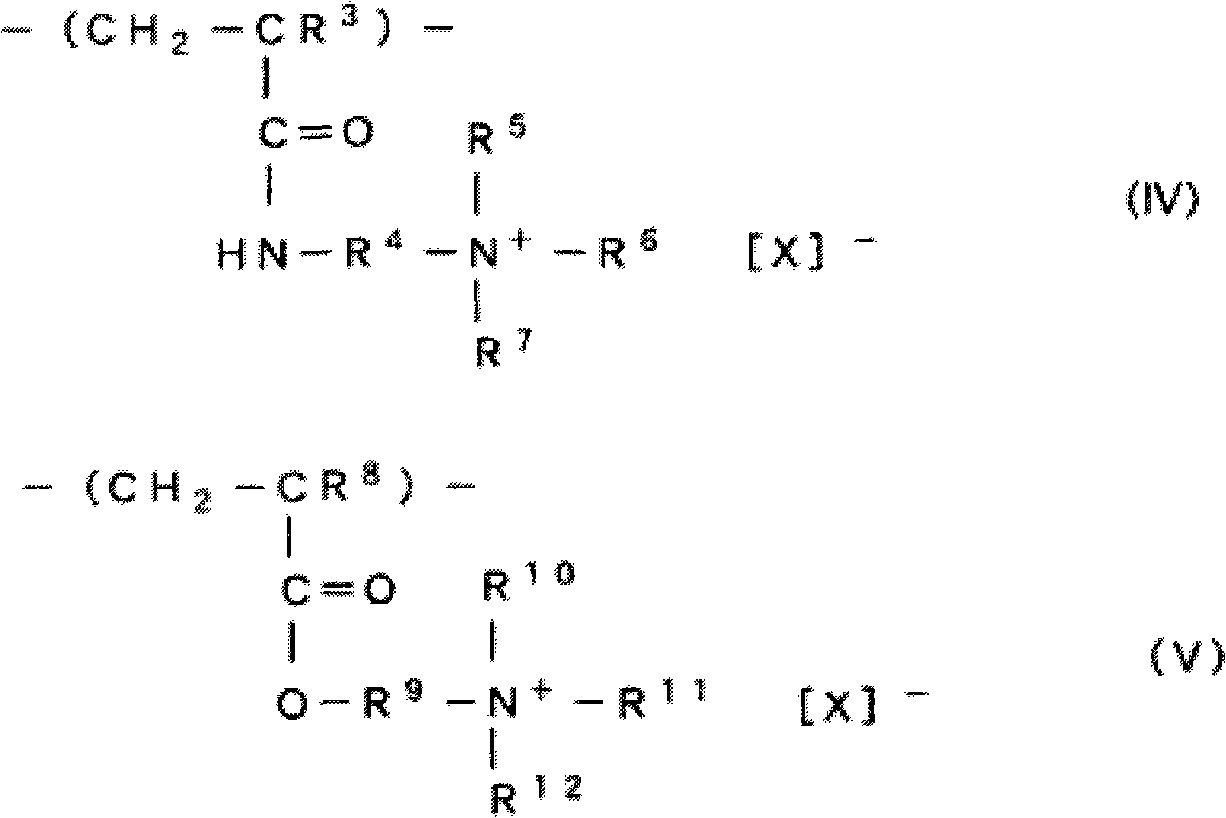

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~4

[0137] With the mixed raw material that is mixed with polyester (2), (3) in the ratio of 90% and 10% respectively as the raw material of the outermost layer (surface layer), with polyester (1) as the raw material of the middle layer, provide respectively to 2 An extruder, after melting at 285°C, co-extrudes two types of three-layer (surface layer / middle layer / surface layer) layer structures on a cooling roll set at 40°C, and then cools and solidifies to obtain Unstretched sheet. Next, the film was stretched 3.3 times in the longitudinal direction at a film temperature of 85° C. using a difference in the peripheral speed of the rolls. On both surfaces of the longitudinally stretched film, the aqueous coating liquids in the separate table were coated by bar coating, respectively. Thereafter, it is introduced into a tenter, dried at 120°C, preheated, stretched 3.8 times in the transverse direction, and then heat-treated at 220°C, and then relaxed by 4% in the transverse directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com