Affixed material for display

A technology for display and stickers, which is applied in display devices, adhesives, instruments, etc., and can solve the problem of entering between the adherend and the micro-suction cup layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0172] Hereinafter, although this invention is demonstrated based on an Example, this invention is not limited to these Examples. In addition, normal temperature means 23 degreeC.

[0173] (Molecular Weight Determination)

[0174] The weight average molecular weight was determined by GPC (gel permeation chromatography).

[0175] Device: "HLC-8020" manufactured by Tosoh Corporation

[0176] Column: "TSK gel GMH" manufactured by Tosoh Corporation HR -H (20)"

[0177] Solvent: THF

[0178] Standard material: polystyrene

[0179] (Measurement of average pore diameter)

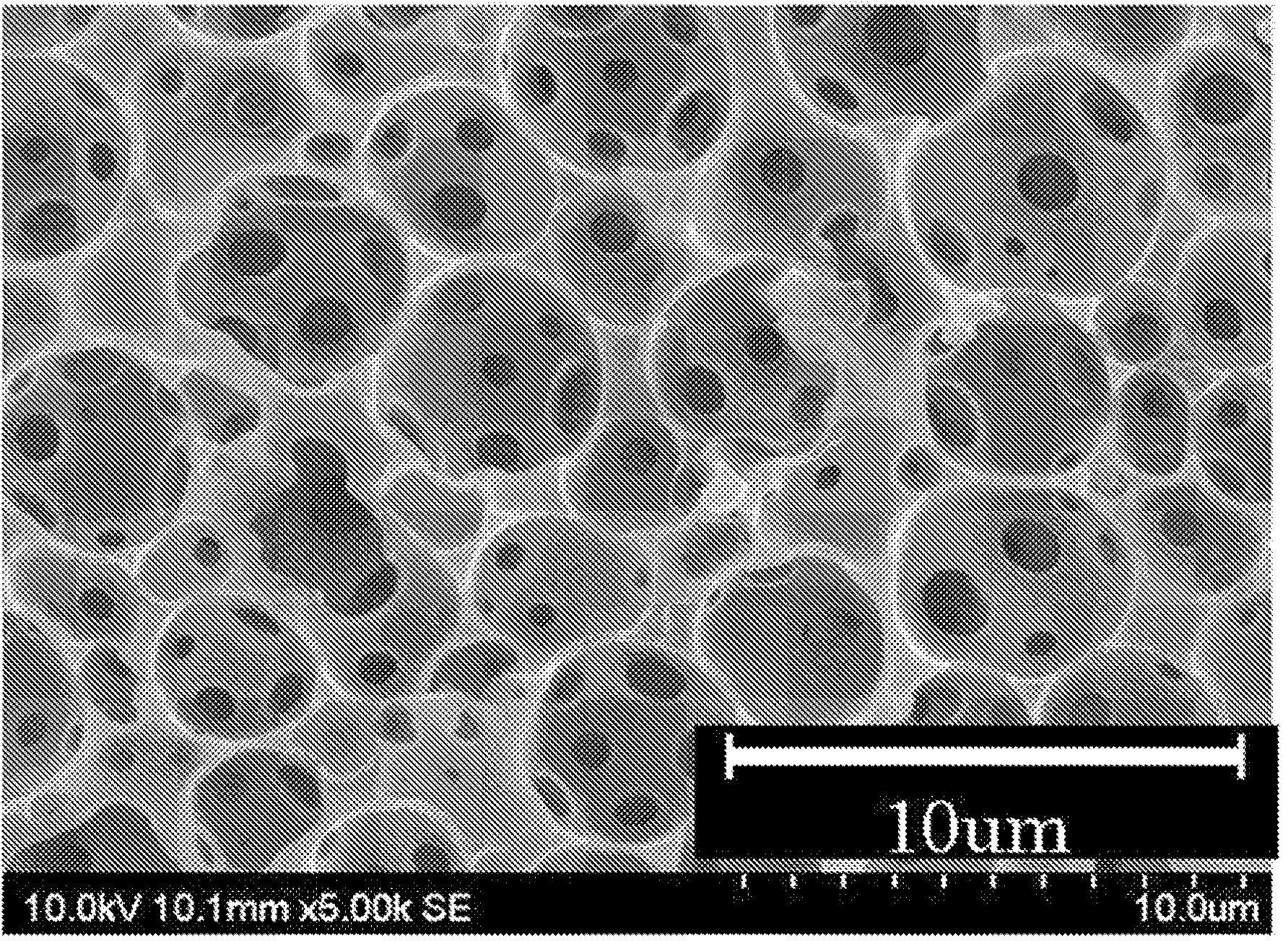

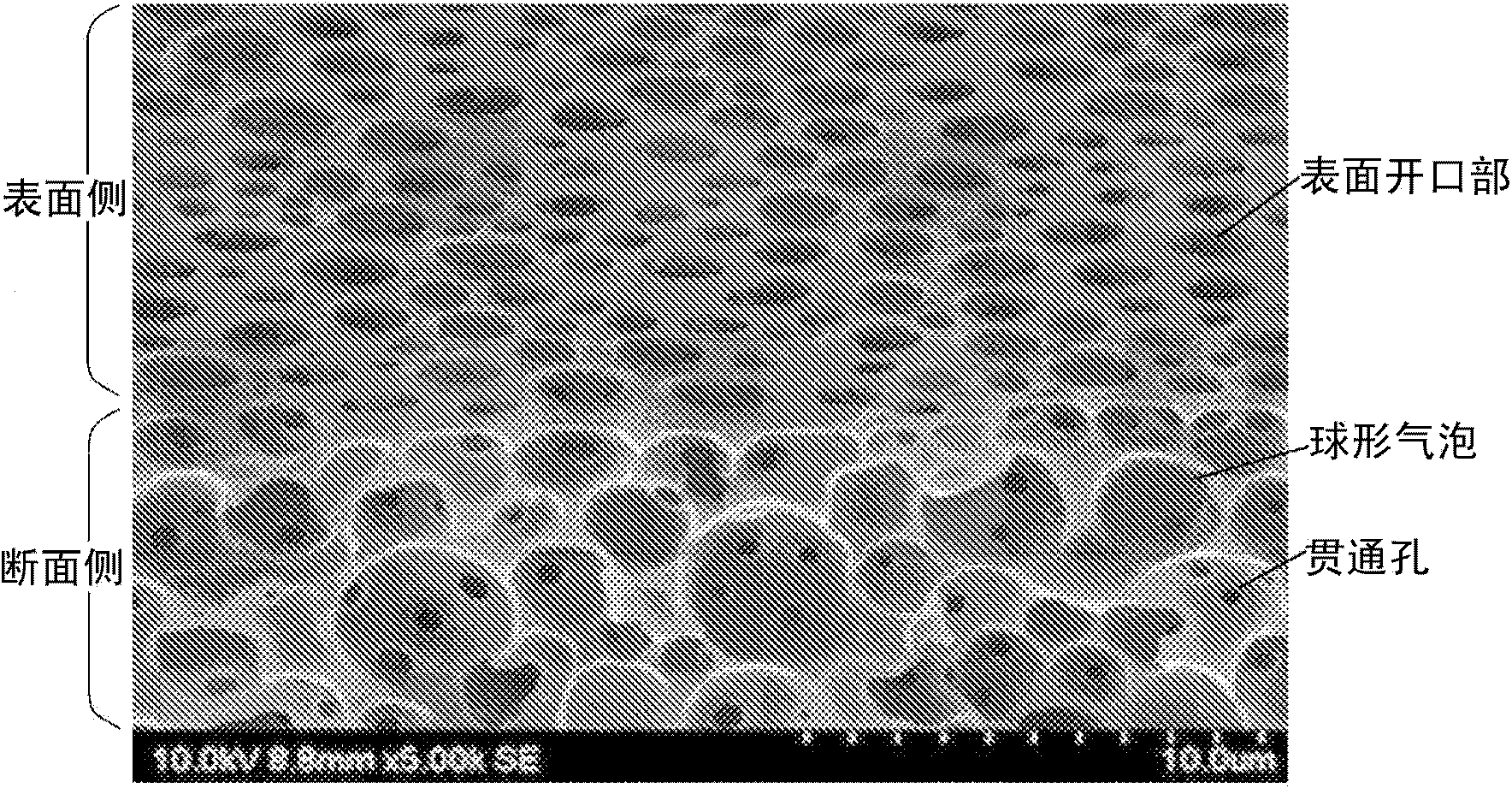

[0180] The produced foam sheet was cut in the thickness direction using an ultramicrotome, and used as a measurement sample. The cut surface of the measurement sample was photographed at 800 to 5000 magnifications using a low-vacuum scanning electron microscope (manufactured by Hitachi, S-3400N). Using the obtained image, the lengths of the major axes of about 30 pores were measured for arbitrary ranges of ...

manufacture example 1

[0196] [Manufacturing Example 1]: Preparation of Mixed Slurry 1

[0197] Into a reaction vessel equipped with a condenser, a thermometer, and a stirring device, 173.2 of a monomer solution composed of 2-ethylhexyl acrylate (manufactured by Toagosei Co., Ltd., hereinafter abbreviated as "2EHA") as an ethylenically unsaturated monomer was introduced. Parts by weight, 100 parts by weight of ADEKA (registered trademark) pluronic L-62 (molecular weight 2500, manufactured by ADEKA Corporation, polyether polyol) as polyoxyethylene polyoxypropylene glycol, dilaurel as a urethane reaction catalyst Dibutyltin dibutyltin (manufactured by Yoshida Chemical Co., Ltd., hereinafter referred to as "DBTL") 0.014 parts by weight, and hydrogenated xylylene diisocyanate (manufactured by Takeda Pharmaceutical Co., Ltd., TAKENATE600, hereinafter referred to as "HXDI") was added dropwise while stirring. ”) 12.4 parts by weight, reacted at 65°C for 4 hours. In addition, the usage-amount of a polyisoc...

manufacture example 2

[0198] [Manufacturing Example 2]: Preparation of Mixed Slurry 2

[0199] 173.2 parts by weight of a monomer solution composed of 2EHA as an ethylenically unsaturated monomer and ADEKA (registered trademark) pluronic L as polyoxyethylene polyoxypropylene glycol were charged into a reaction vessel equipped with a condenser, a thermometer, and a stirring device. 100 parts by weight of -62 (molecular weight 2500, manufactured by ADEKA Co., Ltd., polyether polyol), 0.014 parts by weight of DBTL as a urethane reaction catalyst, and 12.4 parts by weight of HXDI were added dropwise while stirring. React for 4 hours. In addition, the usage-amount of a polyisocyanate component and a polyol component is NCO / OH (equivalent ratio)=1.6. Then, 5.6 parts by weight of HEA was added dropwise and reacted at 65°C for 2 hours to obtain a hydrophilic polyurethane-based polymer / ethylenically unsaturated monomer mixed slurry having acryloyl groups at both ends. The weight average molecular weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com