Thermoplastic polymer composition and molded article

A thermoplastic polymer and composition technology, applied in the directions of graft polymer adhesives, synthetic resin layered products, adhesive types, etc., can solve the problems of complicated steps, increased manufacturing costs, low elongation, etc., Achieve excellent heat resistance and sufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

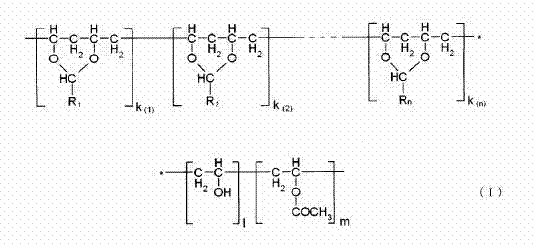

Method used

Image

Examples

preparation example Construction

[0145] The preparation of the thermoplastic polymer composition of the present invention is not particularly limited.

[0146] It may be prepared by any method as long as it can uniformly mix the above-mentioned components used in the thermoplastic polymer composition of the present invention, and a melt-kneading method is usually used. Melting and kneading can be carried out using melting and kneading devices such as a single-screw extruder, a twin-screw extruder, a kneader, a batch mixer, a roll machine, a Banbury mixer, and usually, preferably, can be carried out at 170 to Melt-kneading was carried out at 270° C. to obtain the thermoplastic polymer composition of the present invention.

[0147] The thermoplastic polymer composition of the present invention obtained in this way has a hardness (hereinafter sometimes referred to as "A hardness") obtained by the JIS-A method of JIS K 6253. It is preferably 93 or less, more preferably 30 to 85, and even more preferably 40-75, p...

Embodiment 1~4

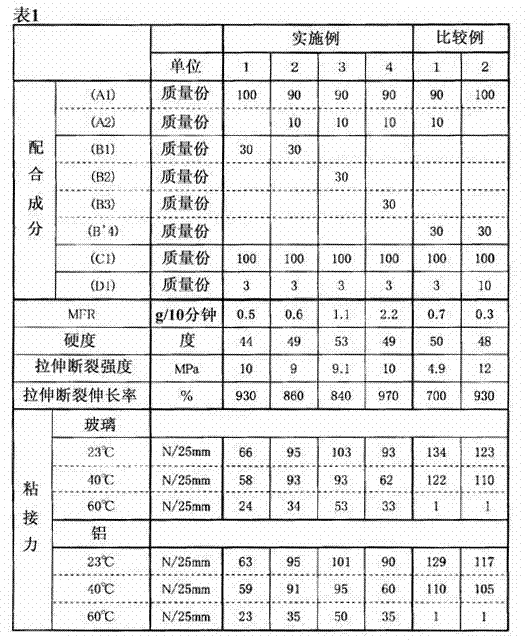

[0206] Examples 1-4, Comparative Examples 1-2 (production of thermoplastic polymer composition sheet)

[0207] Using a batch mixer, the raw materials described in Table 1 were melt-kneaded at the ratio shown in Table 1 under the conditions of 230° C. and screw rotation speed of 200 rpm. The resulting kneaded product was molded at 230°C under a load of 100kgf / cm using a compression molding machine. 2 (9.8N / mm 2 ) under the conditions of compression molding for 3 minutes, thereby obtaining a thermoplastic polymer composition sheet with a thickness of 1 mm.

[0208] The physical properties and characteristics of the obtained thermoplastic polymer composition sheet were evaluated according to the above-mentioned measurement methods. The results are shown in Table 1.

[0209] [Table 1]

[0210]

[0211] As can be seen from Table 1, the thermoplastic polymer compositions obtained in Examples 1 to 4 by blending the polyvinyl acetal resin (B) with a Tg of 80 to 130°C are excell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| degree of acetalization | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com