Modification method for using low-temperature plasma to initiate gas-phase grafting on surface of polyethylene film

A technology of low-temperature plasma and polyethylene film, which is applied in the field of modification of new high-resolution materials, can solve problems such as inability to adapt and lack of large-scale continuous production, improve production efficiency, solve low and unstable peel strength, The effect of high grafting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

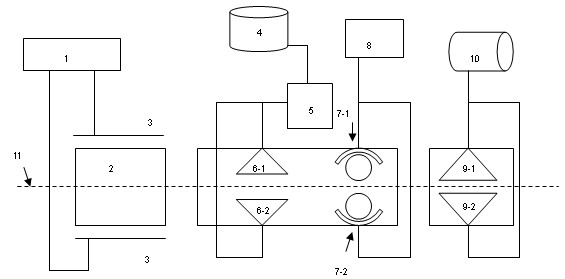

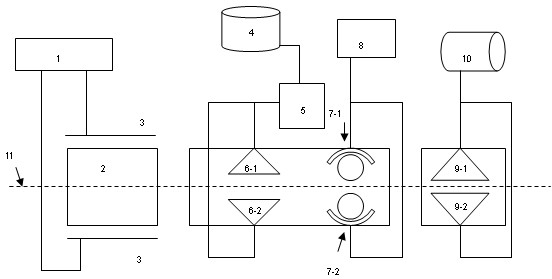

[0021] The steps of the method for modifying the surface gas phase grafting of polyethylene film induced by low-temperature plasma are as follows:

[0022] 1) Use the CW3008 low-temperature plasma processor produced by Nantong Sanxin Electronics Co., Ltd. to perform corona treatment on polyethylene film, with a processing power of 7KW and a voltage of 380V.

[0023] 2) After mixing liquid acrylic acid and ammonium persulfate at a weight ratio of 100:10, it is vaporized through a vaporization chamber at a temperature of 180°C, and sprayed uniformly in gaseous form on the surface of a corona-treated polyethylene film through a nozzle. The uniform spray flow rate of the nozzle in gaseous form is 8L / s;

[0024] 3) After irradiating with ultraviolet light with a wavelength of 365nm and a power of 5000W produced by a high-pressure mercury lamp, the activator is sensitized by ultraviolet light, triggering the gas-phase grafting of acrylic monomers on the surface of the polyethylene f...

Embodiment 2

[0029] The modification method of low-temperature plasma-induced gas-phase grafting on the surface of polyethylene film, its steps are as follows:

[0030] 1) Use the CW3008 low-temperature plasma processor produced by Nantong Sanxin Electronics Co., Ltd. to perform corona treatment on the polyethylene film. The processing power is 5KW and the voltage is 380V. The composition of the polyethylene film is linear with a weight ratio of 1:1. Low-density polyethylene (LLDPE) and low-density polyethylene (LDPE);

[0031] 2) After mixing liquid acrylonitrile and ammonium persulfate at a weight ratio of 100:5, it is vaporized through a vaporization chamber at a temperature of 140°C, and sprayed uniformly in gaseous form on the surface of the corona-treated polyethylene film through a nozzle. The uniform spray flow rate in gaseous form through the nozzle is 5L / s;

[0032] 3) After irradiating with ultraviolet light with a wavelength of 365nm and a power of 5000W produced by a high-pre...

Embodiment 3

[0035] 1) Use a low-temperature plasma processor with a power of 1KW and a voltage of 380V to perform corona treatment on the polyethylene film. The composition of the polyethylene film is linear low-density polyethylene (LLDPE) with a weight ratio of 5:1 and low Density polyethylene (LDPE);

[0036] 2) Liquid acrylic acid with a weight ratio of 100:1 is mixed with ammonium persulfate, vaporized in a vaporization chamber with a temperature of 180°C, and sprayed evenly in gaseous form on the surface of the corona-treated polyethylene film through a nozzle;

[0037] 3) After irradiating with ultraviolet light produced by a high-pressure mercury lamp with a wavelength of 365nm and a power of 500W, ammonium persulfate is sensitized by ultraviolet light, causing acrylic acid to graft in the gas phase on the surface of the polyethylene film. The flow rate of purging is 5 L / s to remove residual monomers to obtain a surface gas-phase grafted polyethylene film.

[0038] After testing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com