Low-odor low-volatilization modified polypropylene material and preparation method thereof

A polypropylene material and low-emission technology, which is applied in the composition and preparation of low-emission modified polypropylene materials, and low-odor fields, can solve the problems of few reports on modified polypropylene composite materials alone, and achieve low production costs , The preparation process is simple, the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

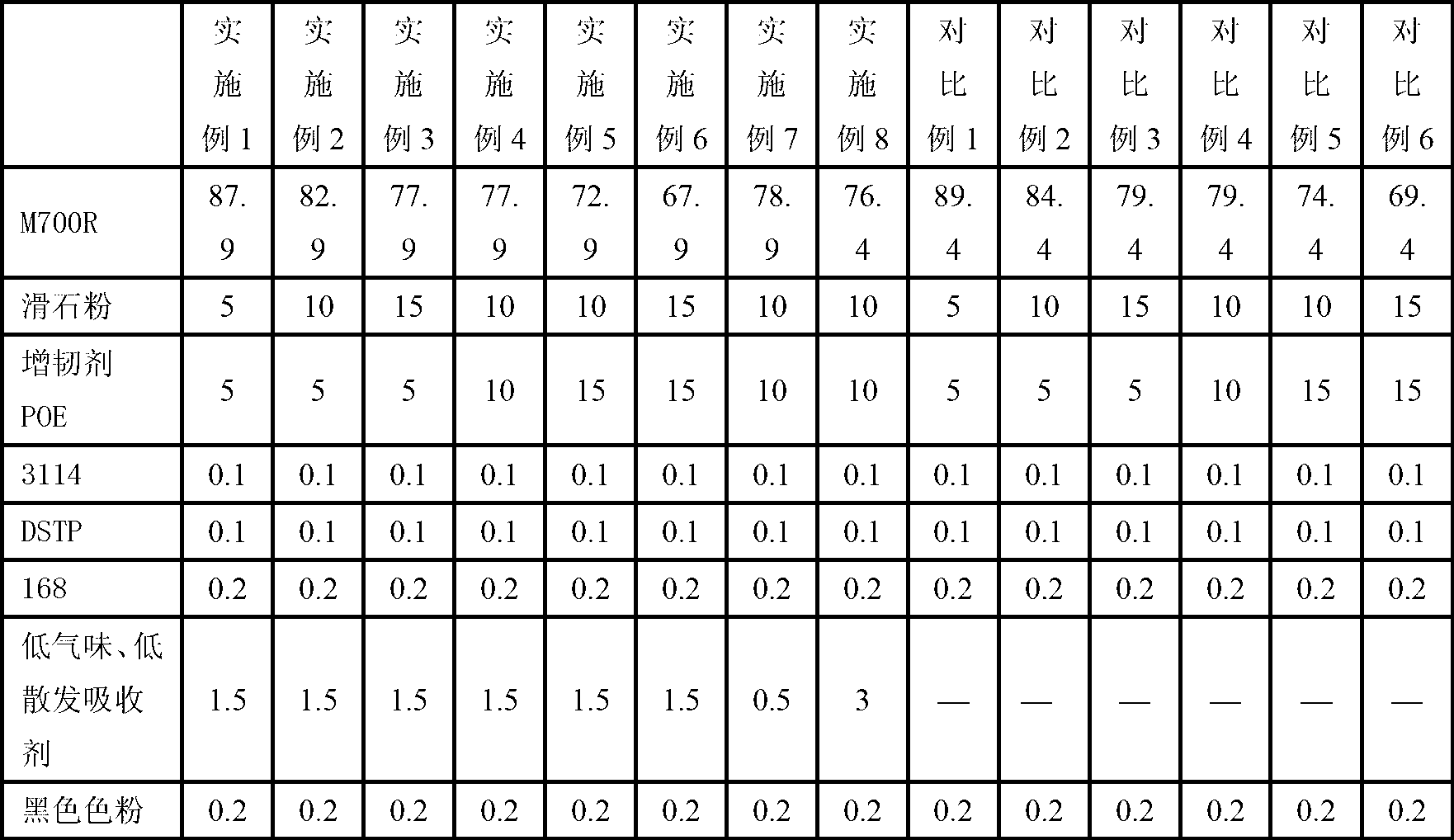

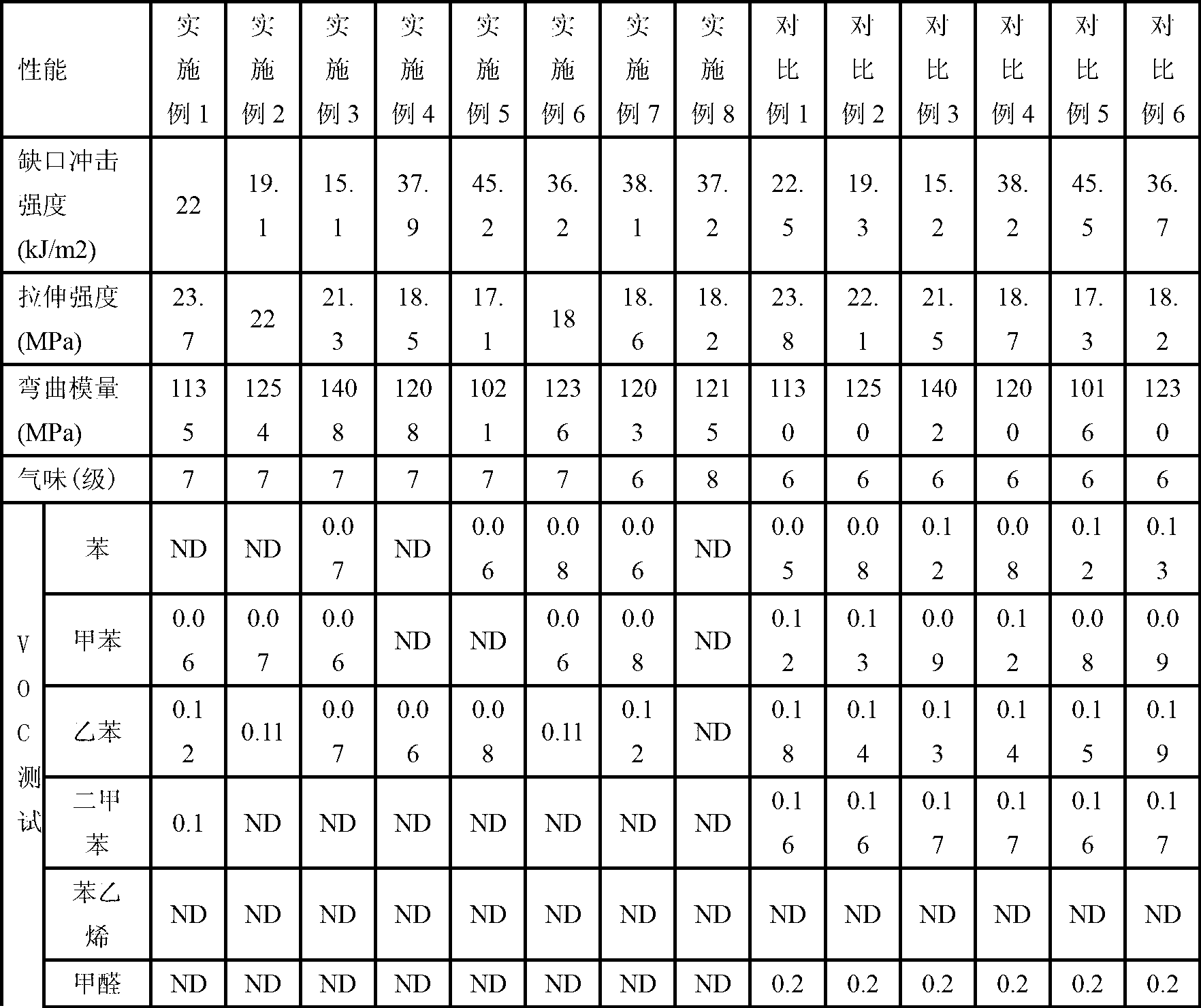

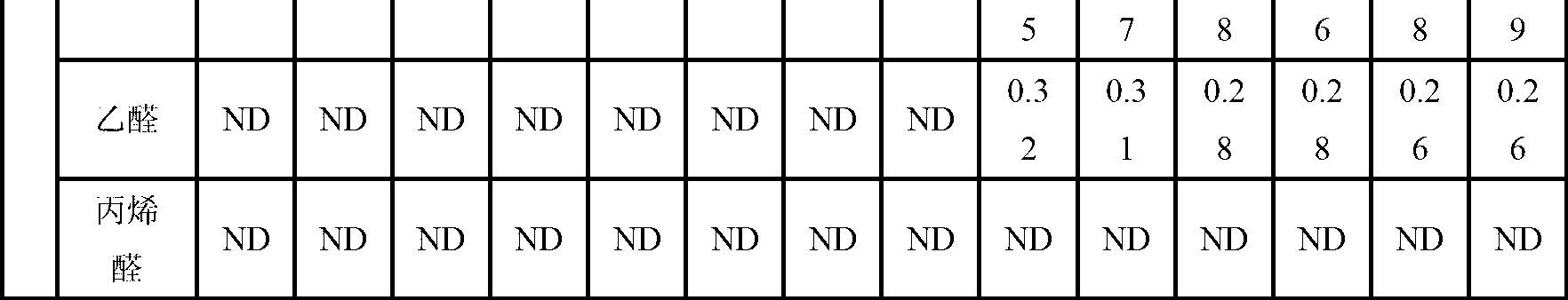

[0033] Below in conjunction with embodiment, the present invention is described in further detail:

[0034] In the composite material formulations of Examples and Comparative Examples, the polypropylene is a block copolymer polypropylene produced by Shanghai Petrochemical, and its trade name is M700R. The particle size range of the talcum powder, calcium carbonate or their composition is 1-10 microns. Described main antioxidant is the DSTP that British ICE company produces, and trade name is Negonox DSTP, and chemical name is octadecyl thiodipropionate, and 3114 that Ciba company produces, and trade name is Irganox3114, and chemical name is 3, Diethyl 5-di-tert-butyl-4-hydroxybenzyl phosphate. The auxiliary antioxidant is 168 produced by Ciba Company, the trade name is Irgafos168, and the chemical name is three (2,4-di-tert-butylphenyl) phosphite. The low-emission absorbent is sodium 13X molecular sieve produced by Shanghai Jiading Molecular Sieve Factory, an inorganic powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com