Preparation method of star polymer

A star-shaped polymer and monomer technology, which is applied in the field of preparation of star-shaped polymers for movable gel systems in high-temperature and high-salt oil reservoirs, can solve the problems of poor water solubility and low sexual viscosity, and achieve the goal of reducing the polymerization initiation temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

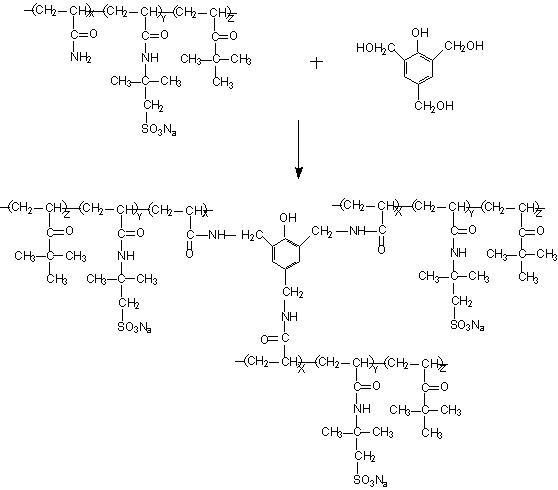

Method used

Image

Examples

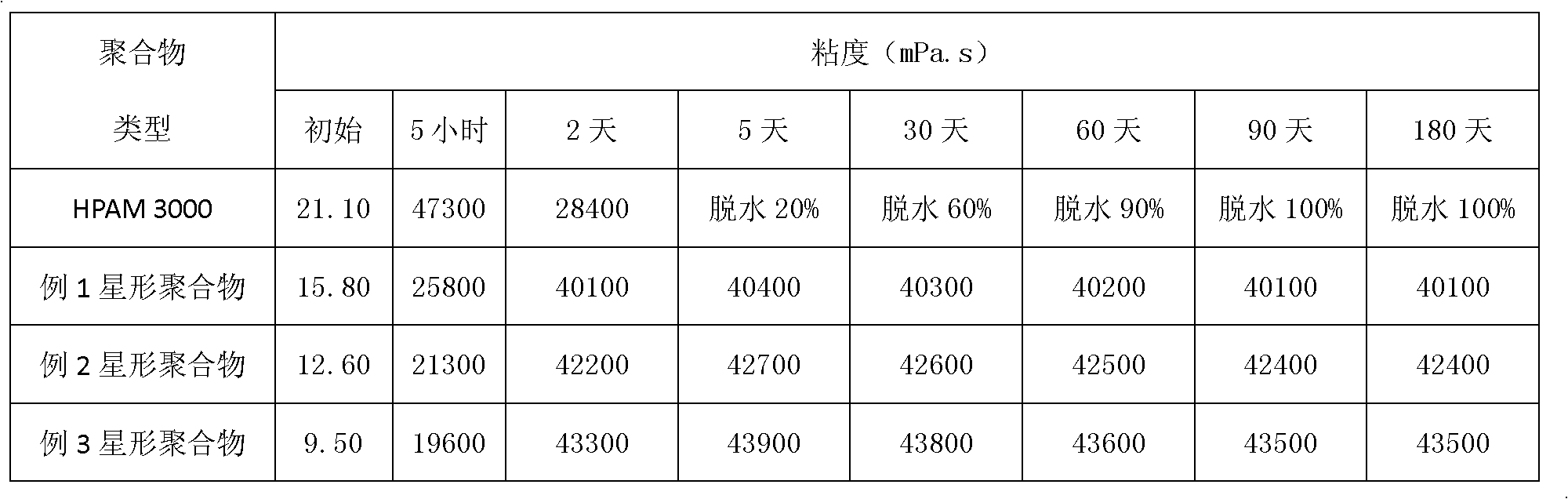

Embodiment 1

[0024] Weigh 15 grams of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 5.56 grams of tert-butyl acrylate (TBA), 15 grams of acrylamide monomer, and an appropriate amount of deionized water to a total liquid volume of 100 grams , added to the ground bottle, stirred and mixed, and prepared into a solution of the required monomer concentration; then 0.005 grams of trimethylolphenol, 0.005 grams of azobisisobutyronitrile, 0.01 grams of urea, and 0.005 grams of formaldehyde. Sodium bisulfate, 0.01 g of disodium edetate and 0.01 g of Span-20 were added to the grinding bottle; the grinding bottle was placed in a constant temperature water bath at 0°C, and after 25 minutes of deoxygenation with nitrogen, 0.005 g of supernatant was added. Add ammonium sulfate and 0.0005 g of hydrogen peroxide aqueous solution, continue to pass nitrogen for 5 minutes, and seal the ground bottle with a latex tube; after standing for 3 hours, raise the temperature of the water bath to 80 ° C, continue ...

Embodiment 2

[0026] Weigh 17 grams of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 3.56 grams of tert-butyl acrylate (TBA), 15 grams of acrylamide monomer, and an appropriate amount of deionized water to a total liquid volume of 100 grams , added to the ground bottle, stirred and mixed, and prepared into a solution of the required monomer concentration; then 0.005 grams of trimethylolphenol, 0.005 grams of azobisisobutyronitrile, 0.01 grams of urea, and 0.005 grams of formaldehyde. Sodium bisulfate, 0.01 g of disodium edetate and 0.01 g of Span-20 were added to the grinding bottle; the grinding bottle was placed in a constant temperature water bath at 0°C, and after 25 minutes of deoxygenation with nitrogen, 0.005 g of supernatant was added. Add ammonium sulfate and 0.0005 g of hydrogen peroxide aqueous solution, continue to pass nitrogen for 5 minutes, and seal the ground bottle with a latex tube; after standing for 3 hours, raise the temperature of the water bath to 80 ° C, continue ...

Embodiment 3

[0028] Weigh 19 grams of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 4.56 grams of tert-butyl acrylate (TBA), 15 grams of acrylamide monomer, and an appropriate amount of deionized water to a total liquid volume of 100 grams , added to the ground bottle, stirred and mixed, and prepared into a solution of the required monomer concentration; then 0.005 grams of trimethylolphenol, 0.005 grams of azobisisobutyronitrile, 0.01 grams of urea, and 0.005 grams of formaldehyde. Sodium bisulfate, 0.01 g of disodium edetate and 0.01 g of Span-20 were added to the grinding bottle; the grinding bottle was placed in a constant temperature water bath at 0°C, and after 25 minutes of deoxygenation with nitrogen, 0.005 g of supernatant was added. Add ammonium sulfate and 0.0005 g of hydrogen peroxide aqueous solution, continue to pass nitrogen for 5 minutes, and seal the ground bottle with a latex tube; after standing for 3 hours, raise the temperature of the water bath to 80 ° C, continue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com