Formation and lamination method for flexible package lithium ion power battery

A power battery and lithium-ion technology, which is applied in the field of flexible packaging lithium-ion power battery formation and rolling, can solve the problems of increased DC internal resistance of the battery, reduced battery liquid retention, and increased safety risks, achieving small battery polarization and improved performance. Capacity utilization and the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for forming and rolling a flexible-packaged lithium-ion power battery, comprising the following steps:

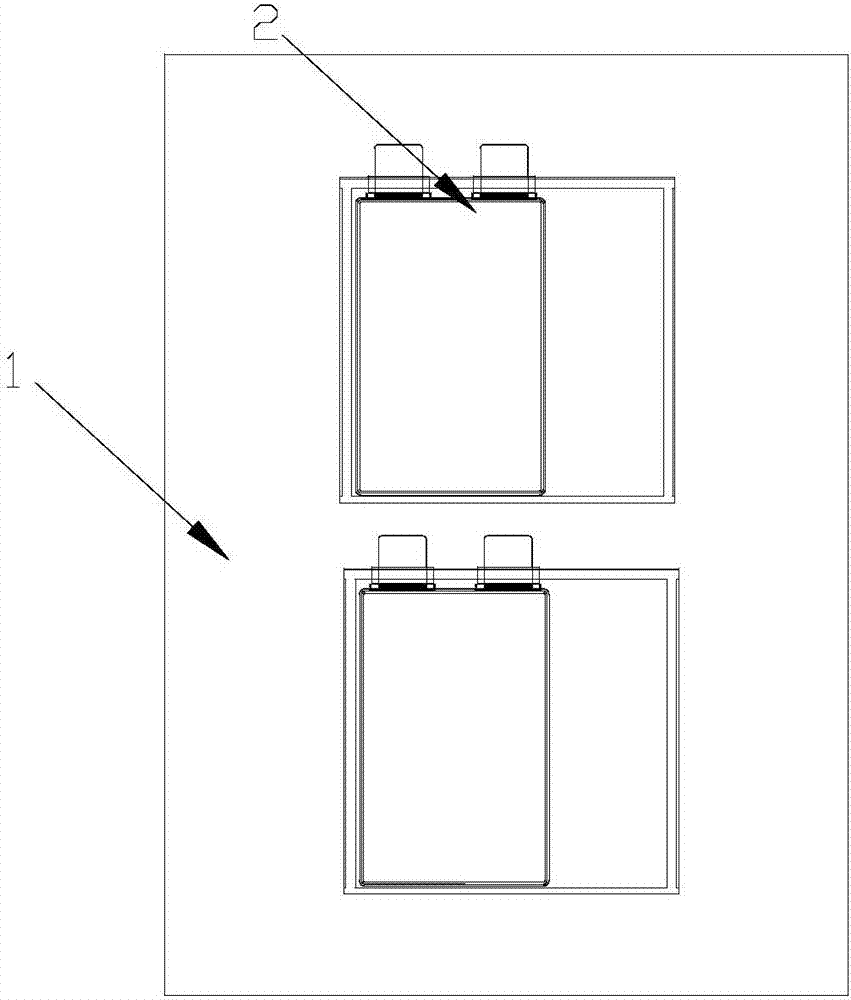

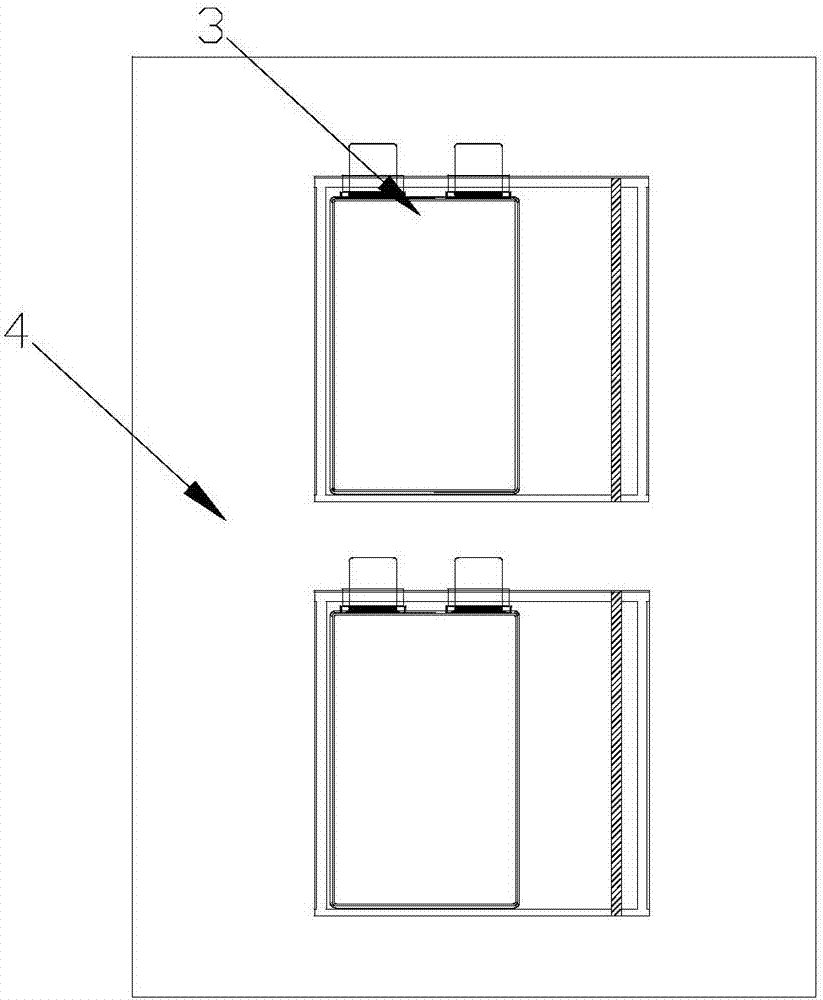

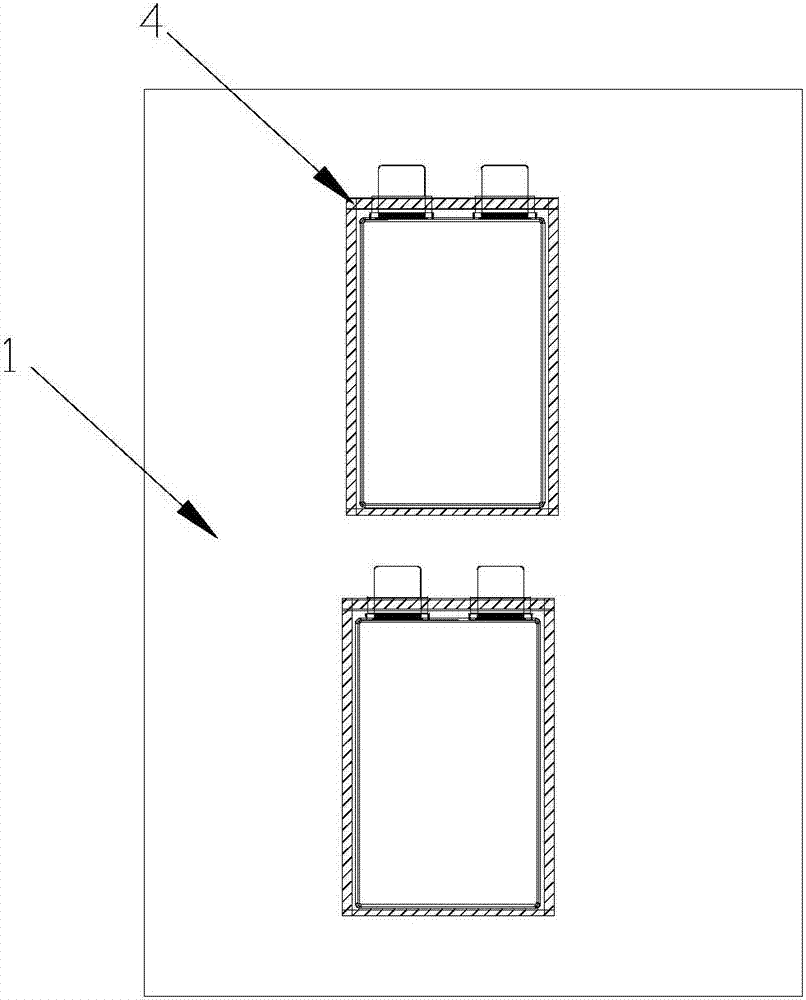

[0033] a. Battery thermal pressure before pre-charging: figure 1 As shown, the pre-charged soft-packaged lithium-ion power battery 2 with an air bag is placed on the flat plate 1 of the press, so that the upper and lower pressing plates of the press completely cover the main part of the battery for rolling. The temperature is 60°C, the pressure is 0.35MPa, and the time is 90s.

[0034] b. Cold pressing of the battery before pre-charging: place the soft-packed lithium-ion power battery on the flat plate of the press, so that the upper and lower pressing plates of the press completely cover the main part of the battery, and perform rolling. The temperature is 10°C, the pressure is 0.35MPa, and the time is 90s.

[0035] c. Pre-charging: degass the soft-packed lithium-ion power battery, and then pre-charge it.

[0036] d. Battery thermal pressure after pre-ch...

Embodiment 2

[0041] A method for forming and rolling a flexible-packaged lithium-ion power battery, comprising the following steps:

[0042] a. Battery hot pressing before pre-charging: place the soft-packed lithium-ion power battery with an air bag on the flat plate of the press, so that the upper and lower pressing plates of the press completely cover the main part of the battery and carry out rolling. The temperature is 45°C, the pressure is 0.1MPa, and the time is 120s.

[0043] b. Cold pressing of the battery before pre-charging: place the soft-packed lithium-ion power battery on the flat plate of the press, so that the upper and lower pressing plates of the press completely cover the main part of the battery, and perform rolling. The temperature is 15°C, the pressure is 0.6MPa, and the time is 60s.

[0044] c. Pre-charging: degass the soft-packed lithium-ion power battery, and then pre-charge it.

[0045] d. Hot pressing of the battery after pre-charging: Place the soft-packed lith...

Embodiment 3

[0050] A method for forming and rolling a flexible-packaged lithium-ion power battery, comprising the following steps:

[0051] a. Battery hot pressing before pre-charging: place the soft-packed lithium-ion power battery with an air bag on the flat plate of the press, so that the upper and lower pressing plates of the press completely cover the main part of the battery and carry out rolling. The temperature is 75°C, the pressure is 0.6MPa, and the time is 60ss.

[0052] b. Cold pressing of the battery before pre-charging: place the soft-packed lithium-ion power battery on the flat plate of the press, so that the upper and lower pressing plates of the press completely cover the main part of the battery, and perform rolling. The temperature is 5°C, the pressure is 0.1MPa, and the time is 60s.

[0053] c. Pre-charging: degass the soft-packed lithium-ion power battery, and then pre-charge it.

[0054] d. Hot pressing of the battery after pre-charging: Place the soft-packed lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com