Aqueous binder, preparing method thereof and electrode slice, isolating membrane and cell using aqueous binder

A technology of water-based adhesives and lithium-ion batteries, which is applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of easy powder falling, unreasonable adhesives, and hard pole pieces, etc., and achieve reduction The use of organic solvents, the improvement of charge and discharge kinetics, and the effect of increasing ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: the preparation of sample 1#~sample 16#

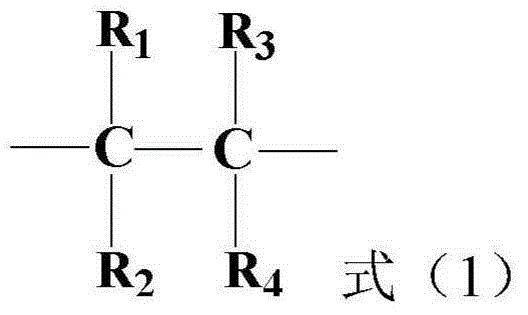

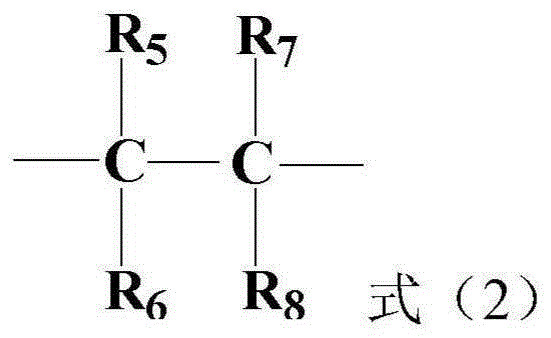

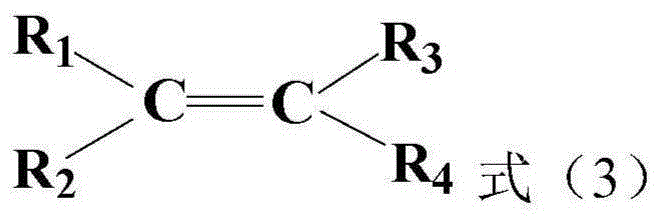

[0086] As shown in Table 1, add the monomers of fluorine-containing polymer A and fluorine-free lipophilic polar polymer B into a non-water-soluble solvent, mix well, start mechanical stirring, and rotate at 600 rpm until the solids are evenly dispersed , to get System I. Put the monomer of the hydrophilic polymer M into a certain amount of deionized water, start stirring at a speed of 100 rpm, until the monomer of the hydrophilic polymer M is completely dissolved, add an emulsifier, and disperse evenly to obtain System II. Mix system I and system II, fully emulsify under mechanical stirring, adjust pH value with phosphate buffer solution, vacuumize, remove non-water-soluble solvent, and obtain system III. Introduce nitrogen or inert gas into System III, remove the air for 1 hour, add the initiator dropwise to System III at a certain temperature, and after a period of reaction, vacuumize and degas to adjust the so...

Embodiment 2

[0091] Embodiment 2: the preparation of sample 17#~19#

[0092] Add 90g of vinylidene fluoride, 0.5g of methyl methacrylate and 0.5g of acrylonitrile into 450g of ethyl acetate, mix well, start mechanical stirring at 600 rpm, until the solids are evenly dispersed, and system I is obtained. Add 20g of lithium acrylate to 480g of deionized water, start stirring at 100 rpm until the lithium acrylate is completely dissolved, add 2g of nonylphenol polyoxyethylene ether emulsifier, and disperse evenly to obtain System II. Mix system I and system II, fully emulsify under mechanical stirring, adjust pH value to about 8 with phosphate buffer solution, vacuumize, remove non-water-soluble solvent, add 4.5g methyl methacrylate and 4.5g acrylonitrile, stir Homogenously, System III is obtained. Introduce helium into system III, remove the air for 1 hour, add 0.15 g of ammonium persulfate dropwise to system III at 30°C, and react for 10 hours, vacuumize and degas, and adjust the solid conte...

Embodiment 3

[0095] Embodiment 3: the making of electrode and performance test

[0096] 1. Production of positive electrode

[0097] The cathode active material LiCoO 2 , conductive carbon powder, and sample 1# are added in N-methylpyrrolidone (NMP) according to the mass ratio=95:2:3 and mixed and stirred evenly to make positive electrode sheet slurry; the prepared positive electrode sheet slurry is evenly coated On both sides of the aluminum foil of the positive electrode current collector, after drying and compacting, the negative electrode sheet of the lithium ion battery is obtained, which is recorded as P1.

[0098] Replace sample 1# with sample 2#~sample 19#, and other conditions remain unchanged, and the obtained positive electrode sheets are respectively recorded as P2~P19.

[0099] 2. Production of negative electrode

[0100] With MAGE graphite (MAGE is a kind of commercial high-capacity, high-pressure dense artificial graphite; Specific capacity is 360mgAh / g), conductive carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com