Cathode material of lithium ion battery and preparation method and lithium ion battery

A technology of lithium-ion batteries and positive electrode materials, which is applied in the manufacture of electrodes, battery electrodes, and electrolyte storage batteries. It can solve the problems of low first-time Coulombic efficiency, low positive electrode gram capacity, and capacity loss of positive electrode active materials to reduce capacity. Loss, increase energy density, increase the effect of capacity play

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a kind of preparation method of the cathode material of lithium ion battery, comprises the steps:

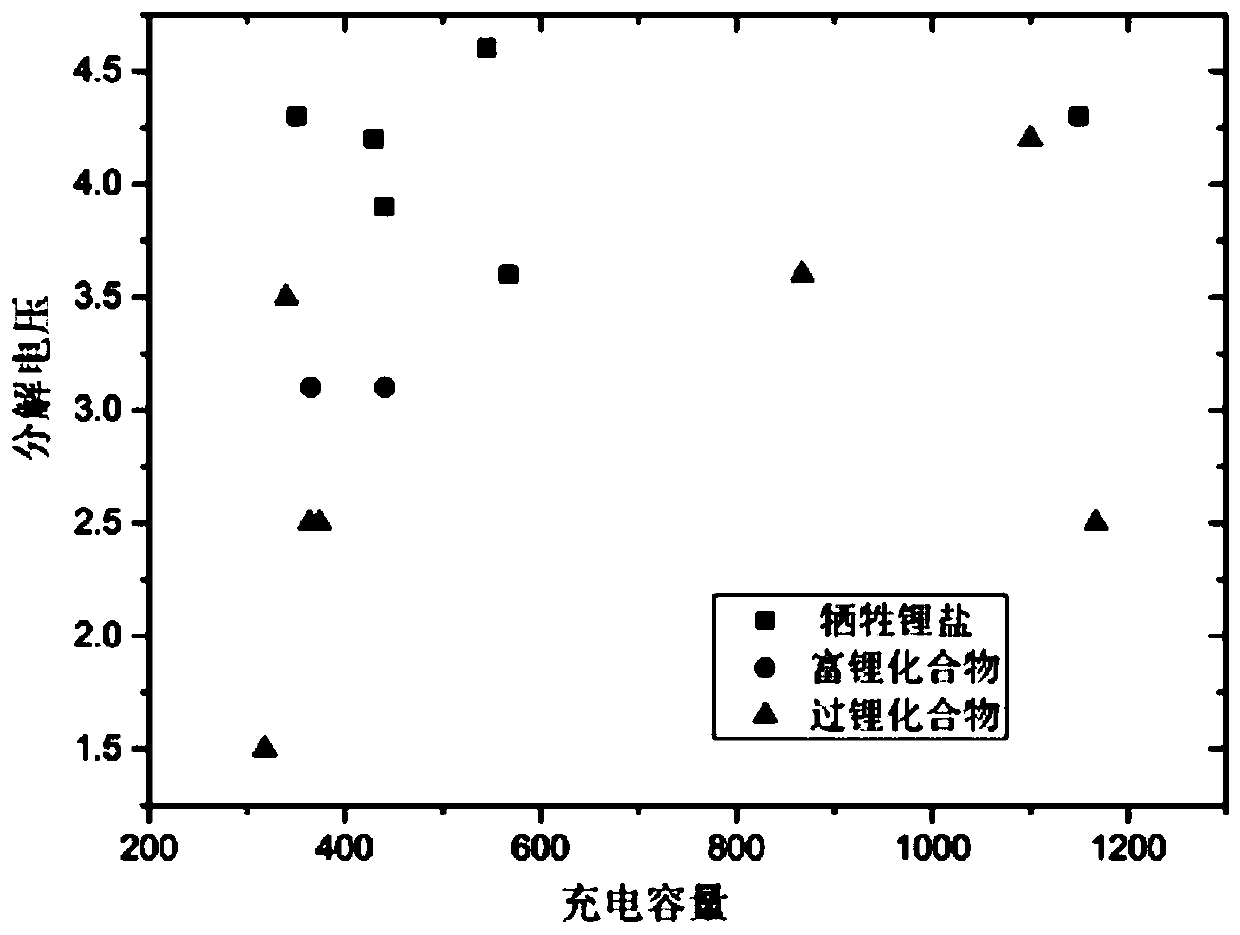

[0028] According to the mass percentage of 77-97%: 1-15%: 0.1-3%: 1-5%, weigh the high-capacity positive electrode active material, lithium supplement material, conductive agent and binder; the chemical formula of the lithium supplement material is: LixMyNz, where, 1≤x≤8, 1≤y≤6, 1≤z≤6, M is one or more metal elements in Fe, Cu, Mn, Zr, Mg, Al, N is O, N , one or more non-metal elements in F, B, S;

[0029] Using a wet homogenization process, the binder and the solvent are added to the mixer at a weight ratio of 1:10, stirred until the binder is fully dissolved, then the conductive agent is added, and the stirring is continued;

[0030] Add the high-capacity positive electrode active material and the lithium supplement material that have been dried, and stir evenly to obtain the final positive electrode material of the lithium ion batte...

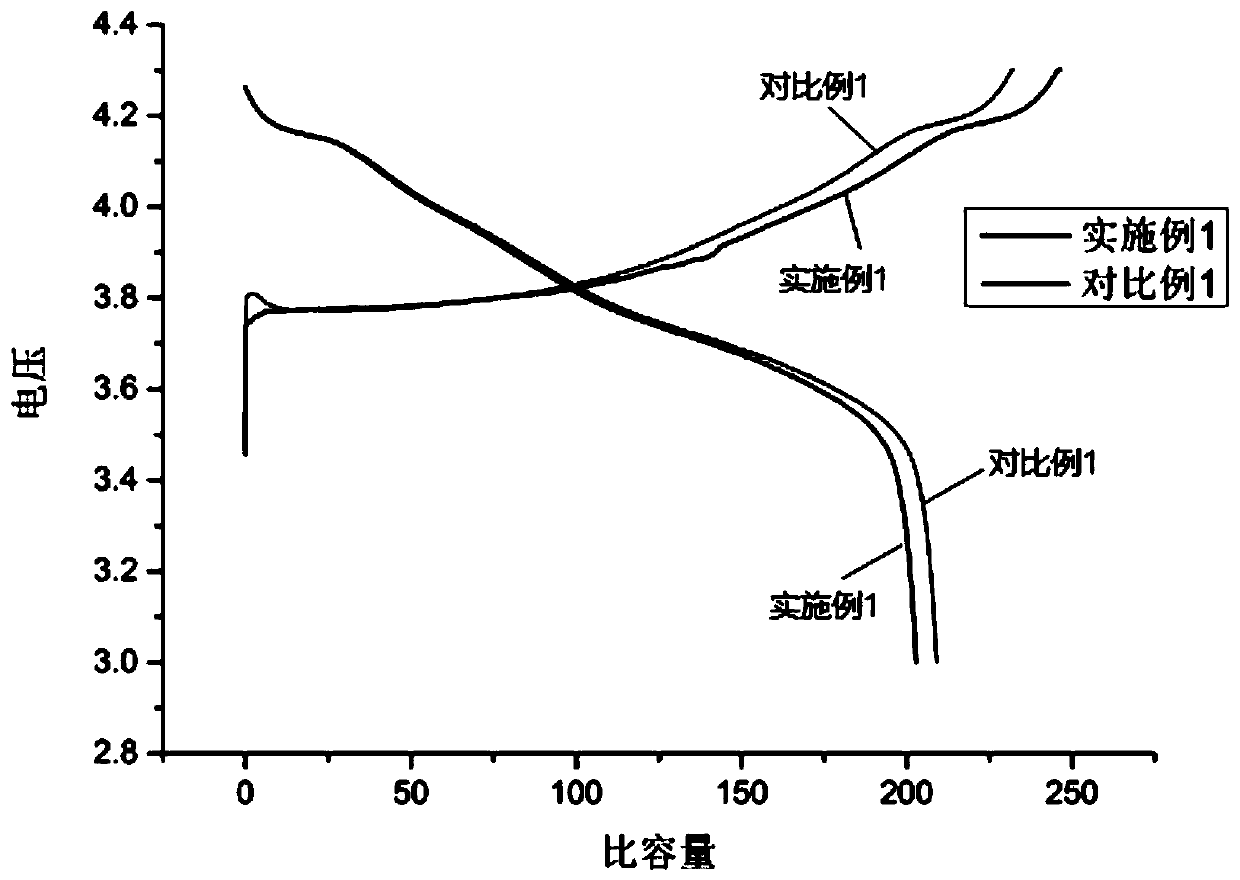

Embodiment 1

[0036] The high-capacity positive electrode active material NCM811 (specific capacity 195mAh / g), the lithium-supplementing material Li 2 NiO 2 , conductive agent SP+CNT, and binder PVDF are weighed according to the weight ratio of 89.2%: 5.8%: 1.8%: 2.2%, and are homogenized by wet homogenization process, and coated on the aluminum foil of the carbon-coated positive electrode current collector. , aluminum foil thickness 12um, carbon coating thickness 1um, coating surface density 380g / m 2 (N / P=15%), after drying, the compacted density is 3.42g / cm 3 , slitting, and die-cutting to obtain the positive electrode sheet prepared in Example 1 of the present invention.

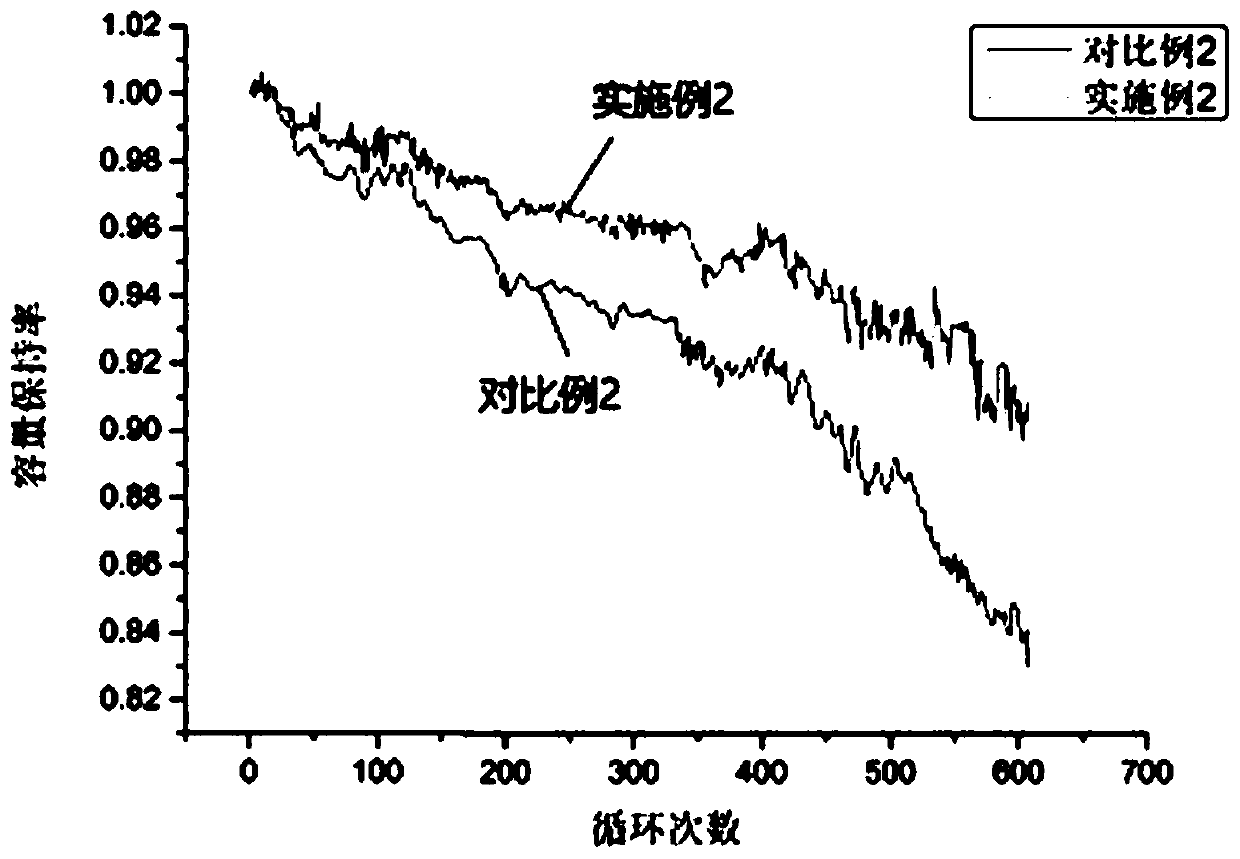

Embodiment 2

[0041] The high-energy cathode active material NCM811 (specific capacity 195mAh / g), the lithium supplement material Li 2 NiO 2 , conductive agent SP+CNT, and binder PVDF are weighed according to the weight ratio of 87.5%: 8.5%: 1.5%: 2.5%, and the wet homogenization process is adopted. First, the binder PVDF and the solvent NMP are weighed in a weight ratio of 1:10 Add to the mixer, stir for 3 hours until the PVDF is fully dissolved, then add the conductive agent SP+CNT and stir for 1 hour, and finally add the dried high-energy positive electrode active material and Li supplementary material Li 2 NiO 2 Stir for 3 hours, use NMP to adjust the viscosity, and control the viscosity range between 6500-8500mPa·s. Coat the uniformly dispersed slurry on carbon-coated aluminum foil, the thickness of the aluminum foil is 12um, the thickness of the carbon-coated layer is 1um, and the coating surface density is 380g / m 2 (N / P=15%), after drying, the compacted density is 3.42g / cm 3 . S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com