600V extra-high voltage aluminum electrolyte capacitor working electrolyte and preparation and application thereof

A technology of aluminum electrolytic capacitors and electrolytes, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of unsatisfactory high-voltage resistance performance and ineffective high-voltage resistance performance, achieve low gas production performance, and improve high-voltage resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

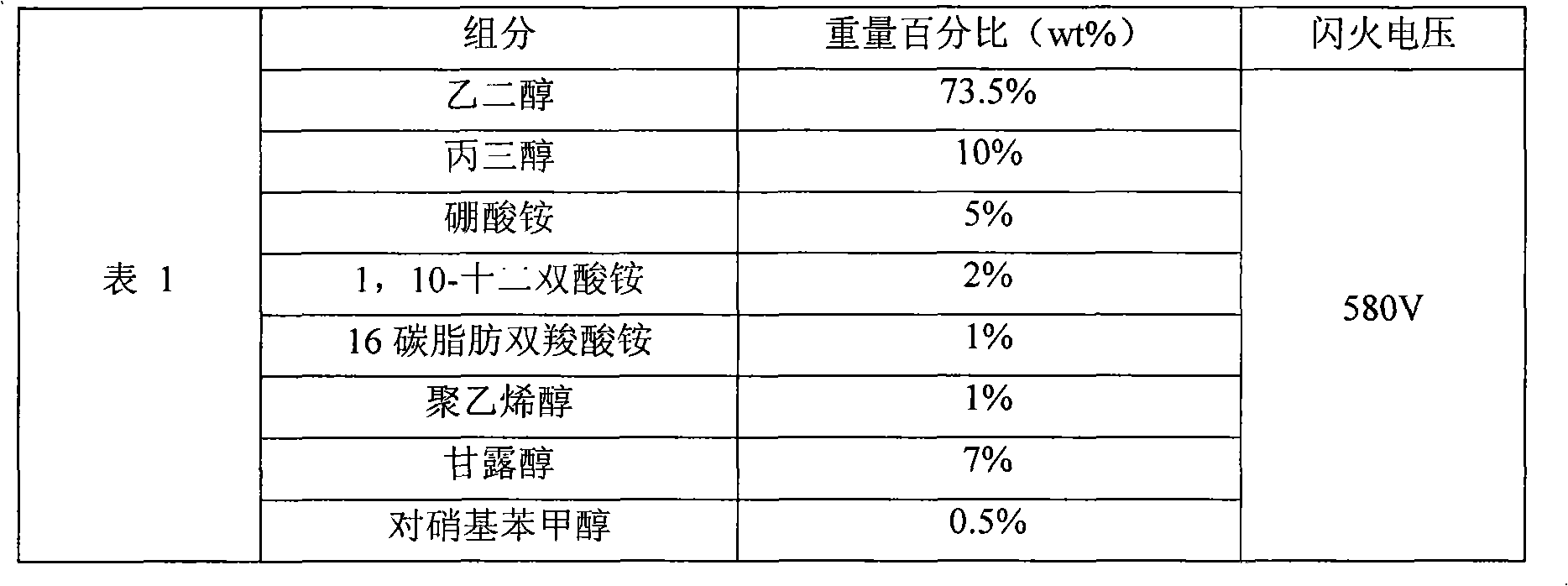

Embodiment 1

[0051]

[0052] Electrolyte preparation:

[0053] (1) According to the formula in Table 1, fully mix ethylene glycol and glycerin, and heat to 60-90°C; then add polyvinyl alcohol, stir well, and heat to 135-155°C;

[0054] (2) Cool the above mixture to 65-80°C through circulating water, add ammonium borate, ammonium 1,10-dodecanoate and 16-carbon fatty ammonium dicarboxylate, stir and mix evenly, then add mannitol, and heat again to 105-135°C; finally add p-nitrobenzyl alcohol, mix evenly and cool naturally to prepare a working electrolyte for ultra-high voltage aluminum electrolytic capacitors.

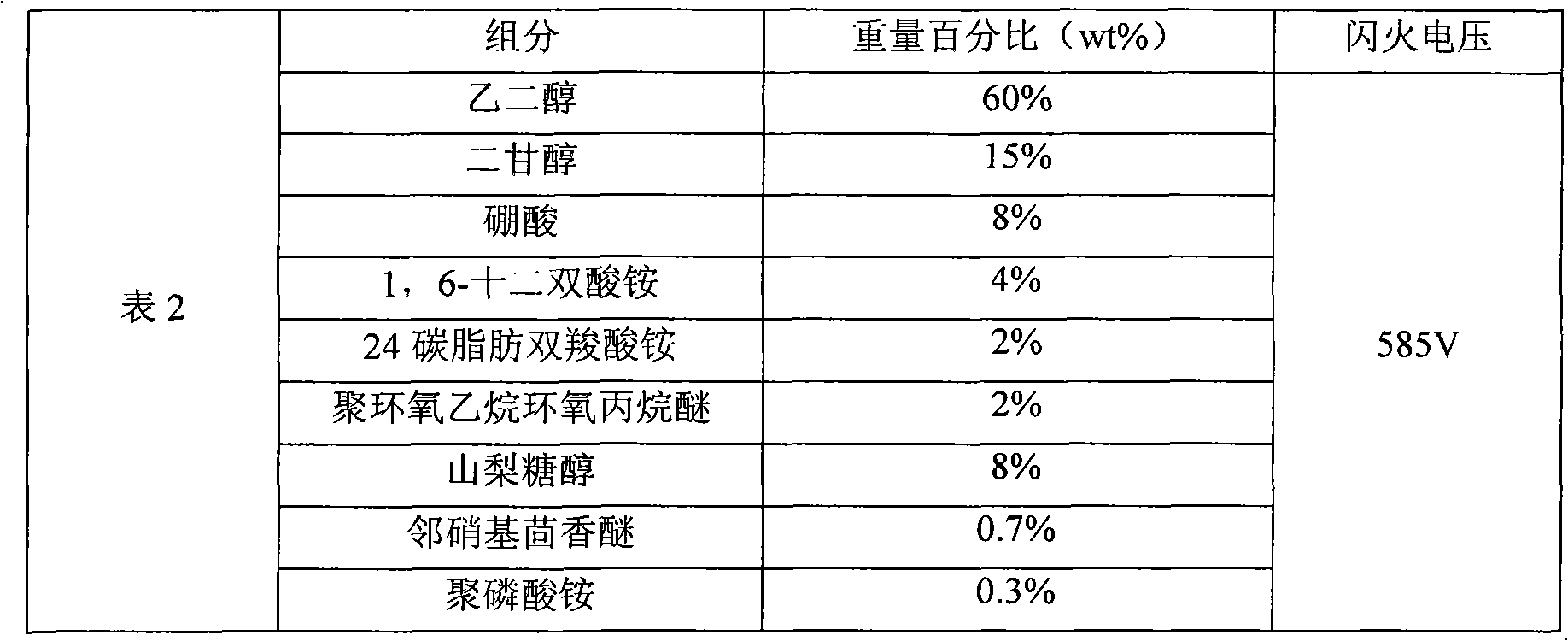

Embodiment 2

[0056]

[0057] According to the composition formula in Table 2, the same preparation method as in Example 1 was used to prepare a working electrolyte for an ultra-high voltage aluminum electrolytic capacitor.

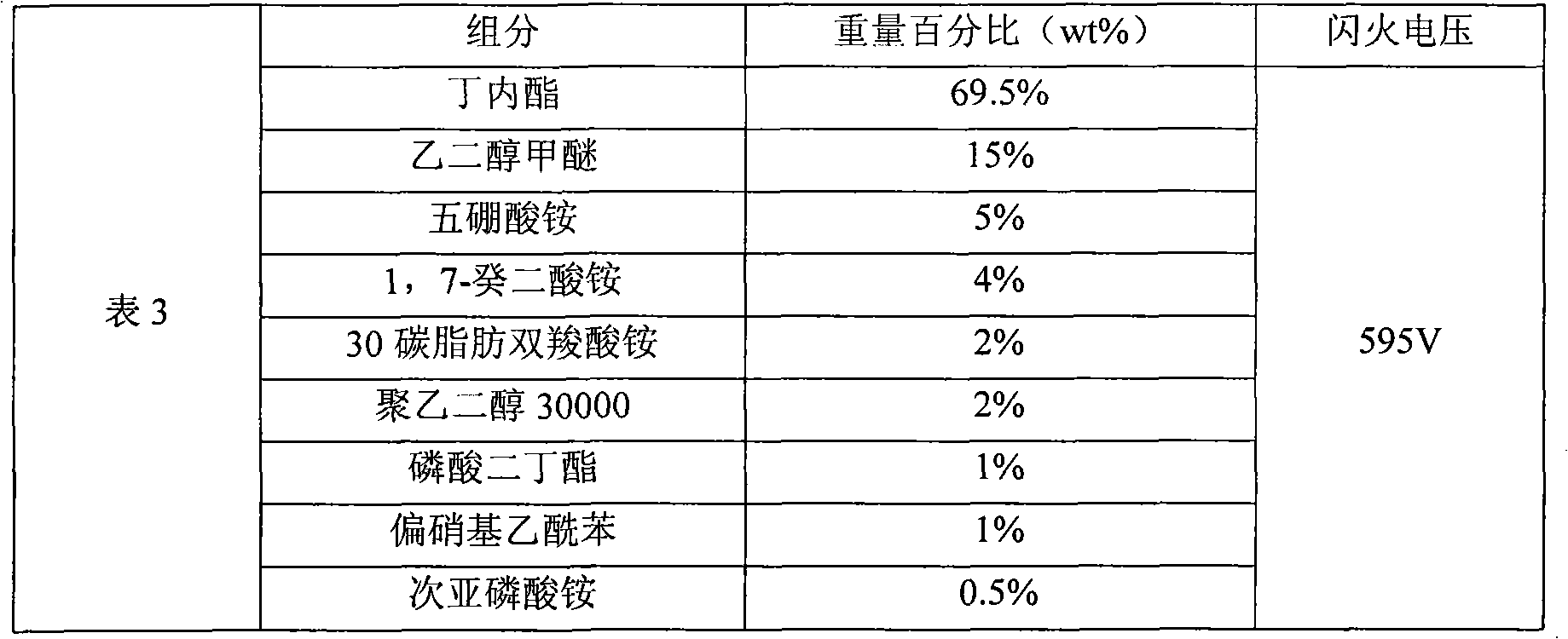

Embodiment 3

[0059]

[0060] According to the composition formula in Table 3, the same preparation method as in Example 1 was used to prepare a working electrolyte for an ultra-high voltage aluminum electrolytic capacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com