Electric hot-water bottle heat-generating body material formula

An electric hot water bottle and heating element technology, applied in the direction of heating element materials, etc., can solve the problems of waste of resources, low thermal conductivity, toxic and side effects of human body, etc., and achieve the effects of small power attenuation, wide temperature range and good insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The material formula of the heating element of the electric hot water bag includes the following components by weight: 75 parts of ceramic powder, 5 parts of adhesive, 2 parts of reinforcing agent, 3 parts of polyvinyl alcohol, 5 parts of tungsten, 2 parts of palladium, 3 parts of iridium, and 2 parts of ruthenium parts, 3 parts of sintering aid.

[0023] Add water and stir ceramic powder into a suspension, heat to 70-80°C, then add binder, reinforcing agent, tungsten, palladium, iridium, ruthenium, disperse at high speed for 10-20min, grind for 2-3h to get slurry, spray dry Sieve the solid powder, mix the sintering aid and the obtained solid powder evenly, dry-press in the tablet machine, hold the pressure for 3-5 minutes to obtain a tablet, and put the tablet into a high-temperature furnace at 1500-1600 ° C for 30 minutes of high-temperature sintering , after cooling, integrally molded to obtain the heating element of the electric hot water bag.

Embodiment 2

[0025] The material formula of the heating element of the electric hot water bag includes the following components by weight: 70 parts of ceramic powder, 6 parts of adhesive, 4 parts of reinforcing agent, 4 parts of polyvinyl alcohol, 6 parts of tungsten, 3 parts of palladium, 3 parts of iridium, and 2 parts of ruthenium parts, 2 parts of sintering aid.

[0026] Add water and stir the ceramic powder into a suspension, heat to 70-80°C, then add binder, reinforcing agent, tungsten, palladium, iridium, ruthenium, disperse at high speed for 10-20min, grind for 2-3h to obtain slurry, and spray dry to obtain For solid powder, mix the sintering aid and the obtained solid powder evenly, dry press it in a tablet machine, hold the pressure for 3-5 minutes to obtain a tablet, put the tablet into a high-temperature furnace at 1500-1600°C, sinter at a high temperature for 30 minutes, and cool The latter integral molding obtains the heating element of the electric hot water bag.

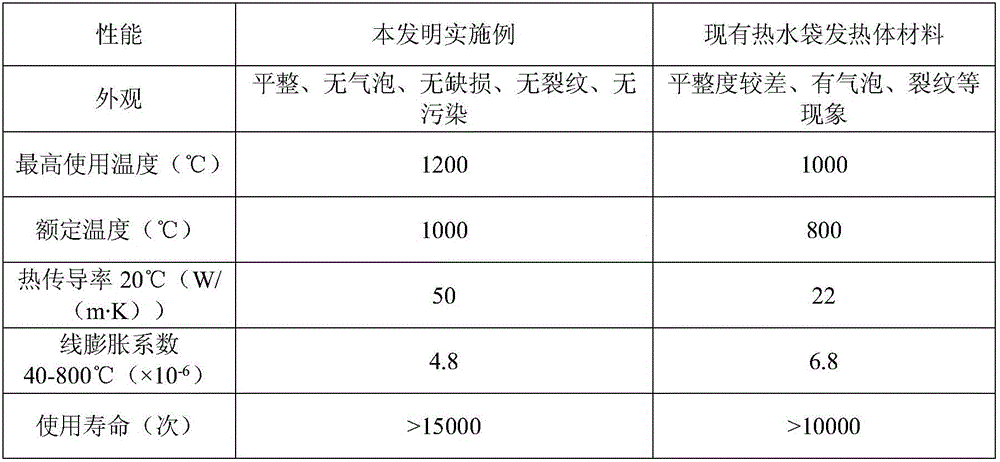

[0027] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com