High voltage pmos transistor

A transistor and high-voltage technology, applied in the field of high-voltage PMOS transistors, can solve the problems of transistor withstand voltage strength limitation, small doping pattern, etc., and achieve the effect of high working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

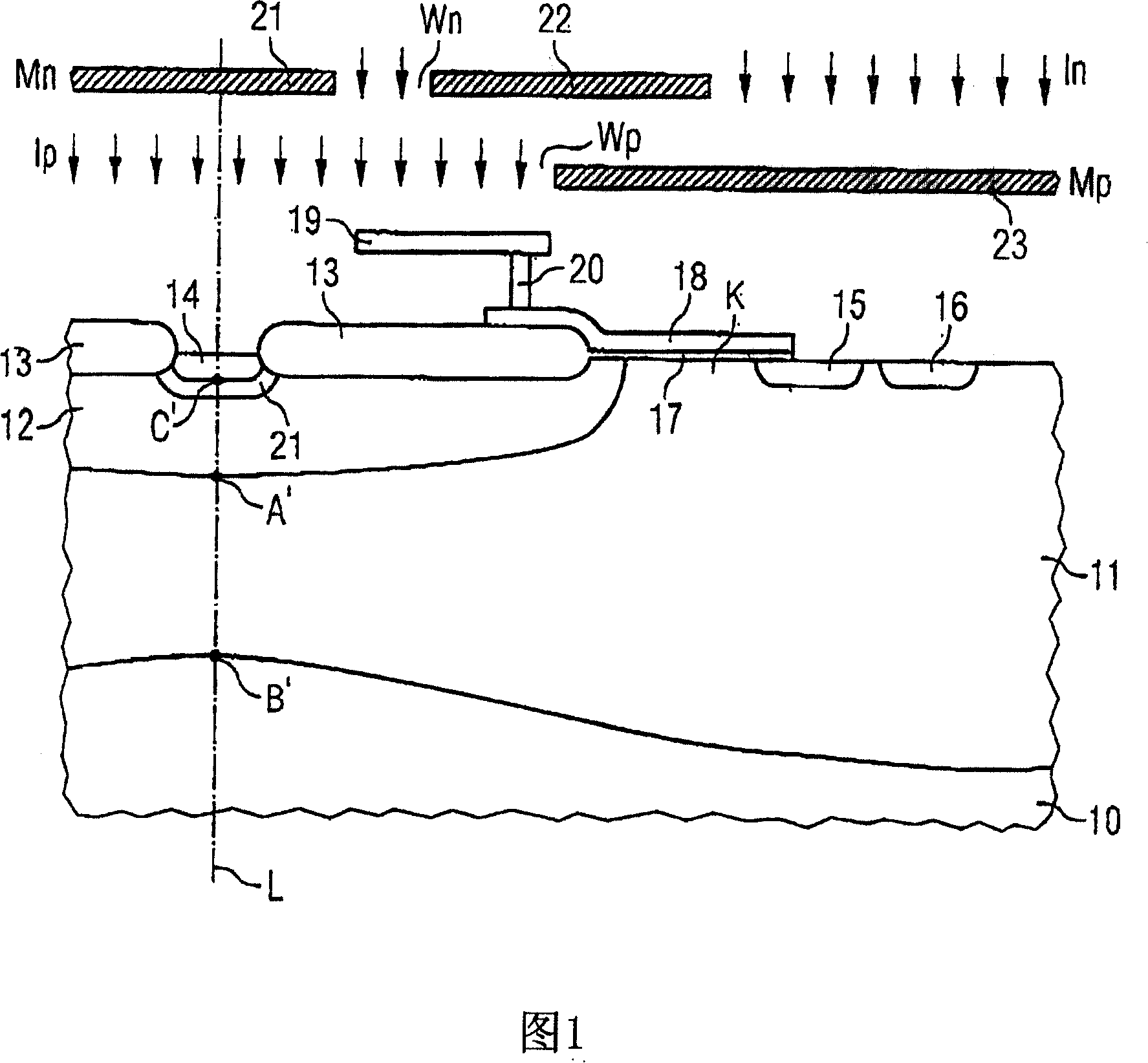

[0021] FIG. 4 shows a refinement of the prior art mentioned at the outset, starting from FIG. 4 for a better overall understanding of the invention. According to FIG. 4 , an n-doped well 411 is arranged on a substrate 410 . A highly doped, p-type conducting region 415 is arranged inside the n-well 411 as a source terminal. Next to it is a highly doped, n-type conductive region 416 which can be used as a ground terminal (Body). A channel region K is connected to the other side of the source region 415 , and a gate electrode 418 , for example composed of polysilicon, is arranged above the channel region K insulated by a gate oxide 417 .

[0022] Arranged in the direction of the drain are field oxide regions 413 which have openings for accommodating a highly doped, p-conducting drain 414 . Below the drain 414 and the field oxide region 413 , a p-doped well 412 is arranged inside the n-doped well 411 , which extends laterally into the channel region. The gate electrode 418 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com