Large and permanent magnet wind turbine generator scatteredly embedded winding stator insulation mechanism

A wind turbine, stator insulation technology, applied in the shape/style/structure of winding insulation, wind power generation, laying solid insulation, etc., to achieve the effect of strong anti-corona ability, low cost and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

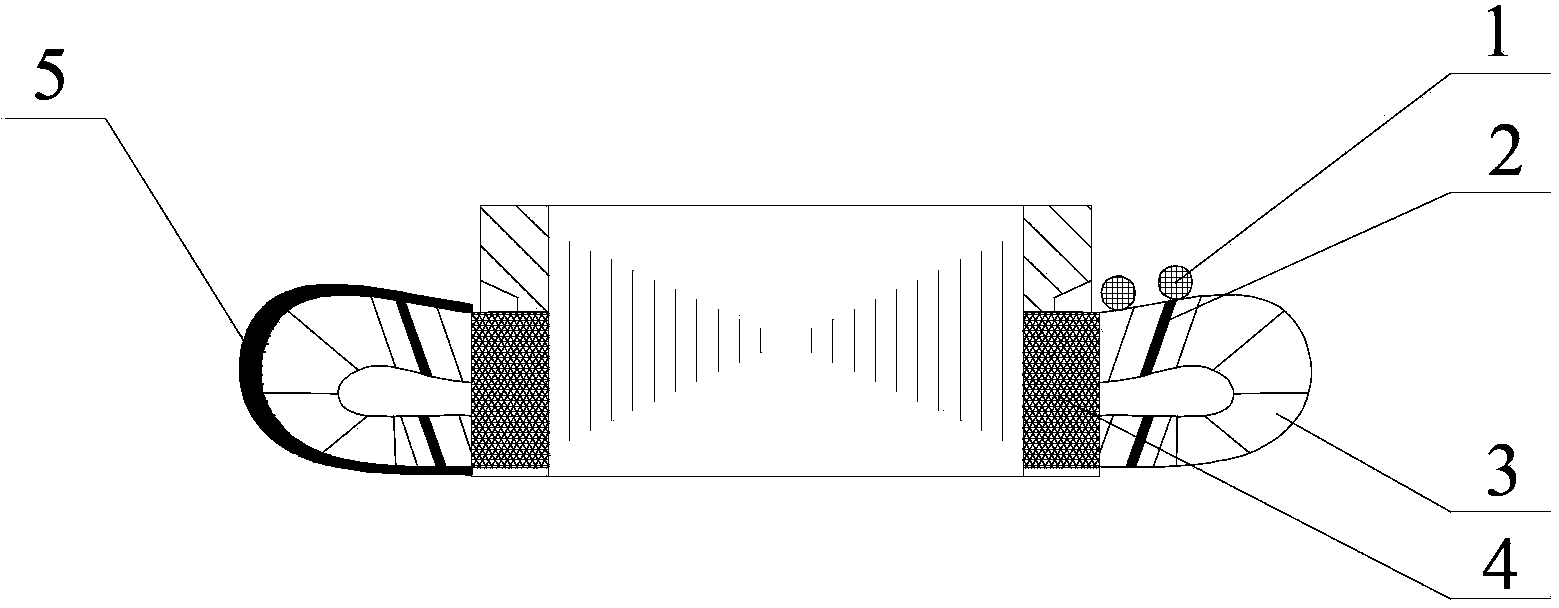

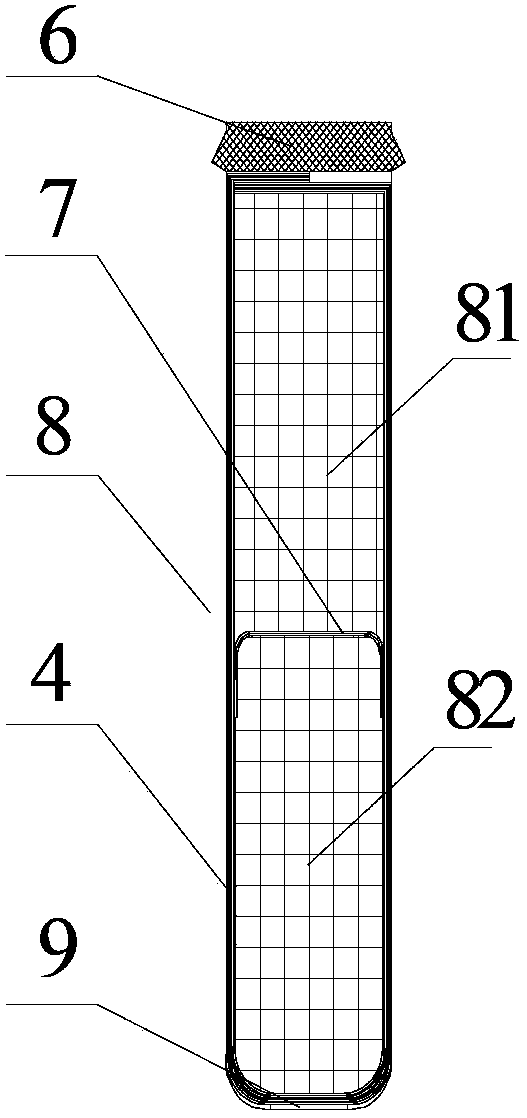

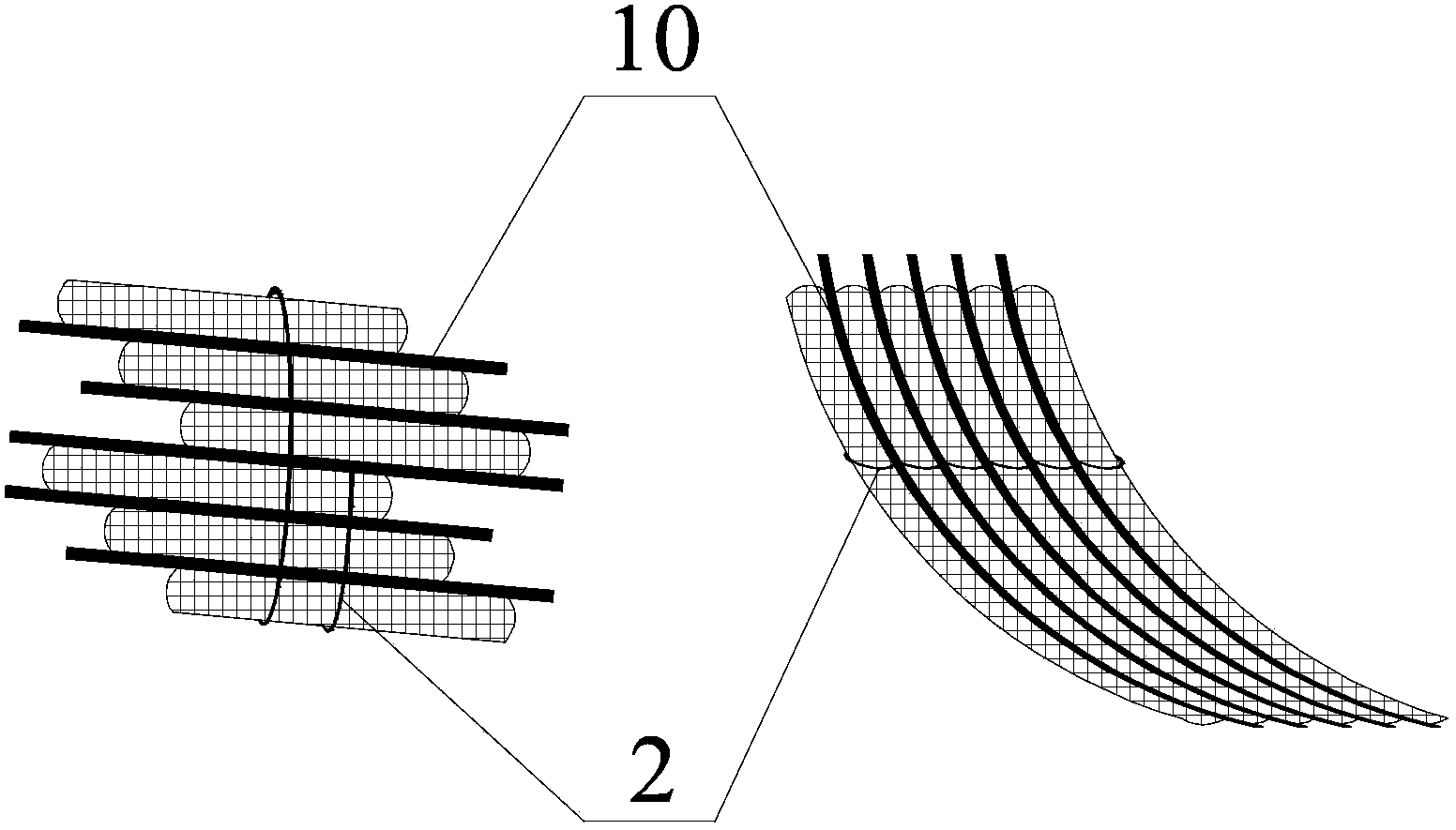

[0039] A stator insulation mechanism with scattered embedded windings for large-scale permanent magnet wind power generators, its structure is as follows: Figure 1-3 As shown, it includes slot insulation components and end insulation components, wherein the slot insulation components include slot insulation 4, slot bottom liner 9, slot wedge 6, intermediate insulation 7 and loose embedded wire winding 8, and slot wedge 6 is located at One end of the loose and embedded wire winding 8, the scattered and embedded wire winding 8 is composed of an upper winding 81 and a lower winding 82, the intermediate insulation 7 is arranged between the upper winding 81 and the lower winding 82, and the slot insulation 4 is arranged outside the loose and embedded wire winding 8 , The slot bottom liner 9 is located at the bottom of the slot insulation 4 . The end insulation assembly includes the end interphase insulator 10, the end insulation 3, the binding rope 2, the soft end collar 1 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com