Megawatt wind power blade, assembling and manufacturing method thereof and blade tip manufacturing method

A technology for wind power blades and manufacturing methods, which is applied in the field of megawatt-level wind power blades and their assembly, manufacturing, and blade tip manufacturing. It can solve the problems of poor implementability and low reliability of lightning protection, and achieve implementability and reliability. sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

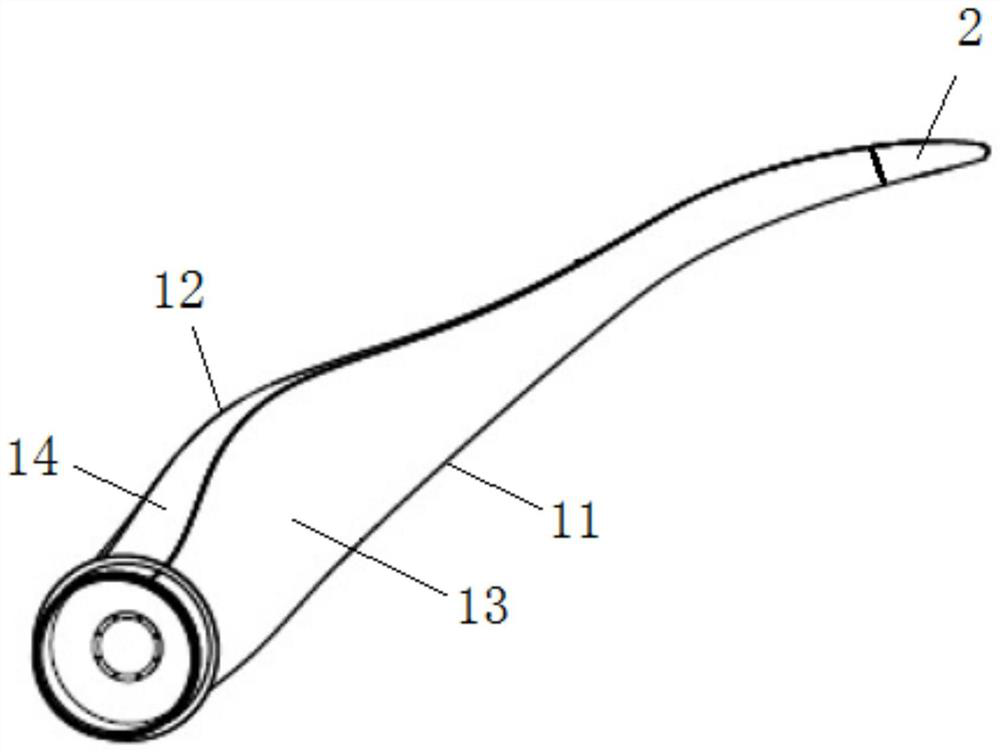

[0054] This embodiment provides a specific implementation of megawatt-level wind power blades, such as figure 1 As shown, it includes: a blade body 1 and a detachable blade tip 2, the blade body has: a leading edge 11, a trailing edge 12, a windward surface 13 and a leeward surface 14, the root of the blade body is used to connect with the shaft, the blade body A replaceable blade tip 2 is attached to the top of the blade. With the development of blade tip extension and synergistic technology, the length of the blade is getting longer and longer. The length of the blade tip 2 in this embodiment is between 0.2-5m, and the connection surface between the blade tip 2 and the blade body 1 is in the blade thickness direction. Not less than 10cm, the shape of the connecting surface between the blade body and the blade tip is the same, and the surface of the connection area between the blade body 1 and the blade tip 2 has a smooth transition to ensure the continuity of the aerodynamic...

Embodiment 2

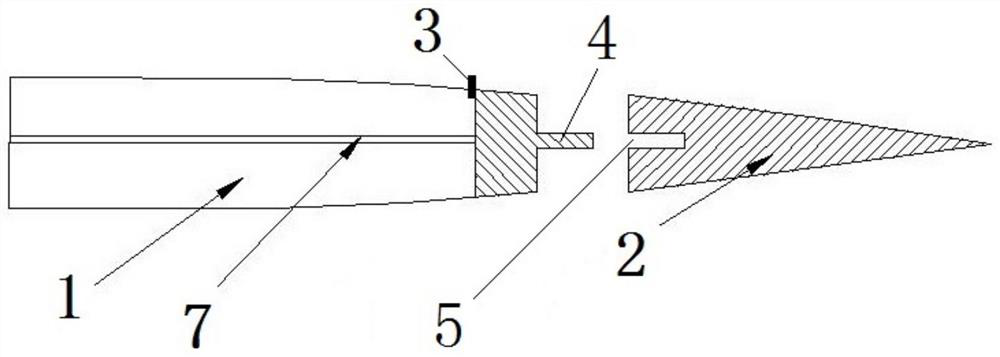

[0062] This embodiment provides a specific implementation of wind power blades, such as image 3 As mentioned above, the structure of the wind power blade of this embodiment is substantially the same as that of Embodiment 1, the difference is that the installation structure of this embodiment includes: a post 4 and a slot 5, and the post 4 is arranged on the blade tip 2 , the slot 5 is arranged on the blade body 1. At this time, since the post 4 is a part of the blade tip 2, there is no need for the slot 5 to be insulated.

[0063] In this embodiment, the part of the lightning receptor 3 constitutes the slot 5, and the slot 5 is used to cooperate with the post 4 at the root of the blade tip 2. When connecting, the post 4 on the tip 2 Insert it into the slot 5 at the end of the air-termination device 3, and then fix it with glue to complete the installation. In addition, as an alternative implementation, the blade tip 2 and the lightning receptor 3 may be fixed by other conven...

Embodiment 3

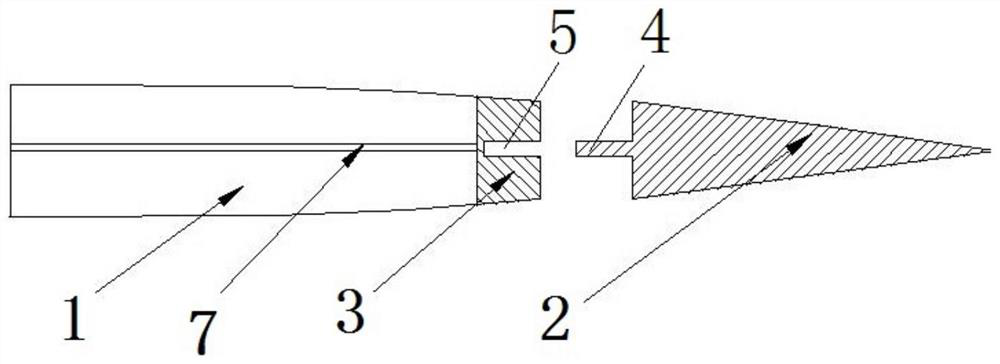

[0065] This embodiment provides a specific implementation of wind power blades, such as Figure 4 As mentioned above, the structure of the wind power blade of this embodiment is substantially the same as that of Embodiment 2, the difference is that: the root of the blade tip 2 of this embodiment is also provided with a slot 5, and then a connecting strip 6 is used to connect the lightning receptor 3 and The blade tips 2 are respectively connected.

[0066] Specifically, when connecting, the two ends of the connecting strip 6 are respectively inserted into the slot 5 of the air receptor 3 and the slot 5 of the blade tip 2, and then glued and fixed with glue, the installation can be completed. In addition, as an alternative implementation, the blade tip 2 and the lightning receptor 3 may be fixed by other conventional fixing methods other than gluing, for example, fasteners or mortise and tenon fixing may be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com