Submarine high voltage cable and manufacturing method thereof

A technology of high-voltage cables and conductive units, which is applied in the direction of submarine cables, cable/conductor manufacturing, insulated cables, etc., and can solve problems such as waste of resources and large redundancy of armor layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

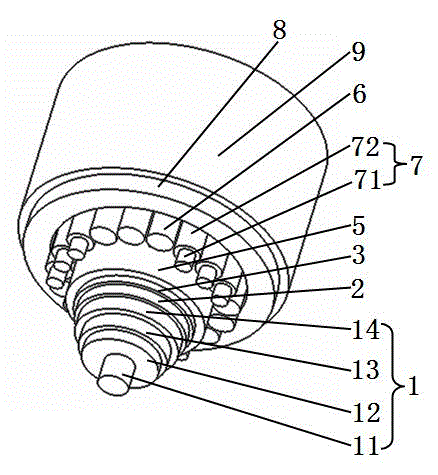

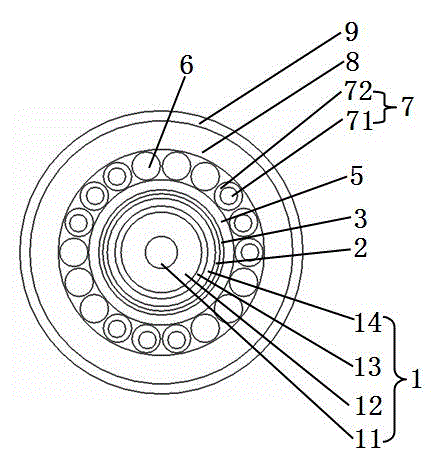

[0058] please see figure 1 and figure 2 , a submarine high-voltage cable, which is characterized in that it is composed of a conductive unit 1, a metal shielding layer 2, a water-blocking layer 3, an inner sheath 5, an armored layer, an outer sheath 8, and an outer sheath protection from the inside to the outside. The conductive unit 1 is composed of a conductor 11, an insulating layer 12 that is extruded and coated outside the conductor, an insulating shielding layer 13 outside the insulating layer, and a conductor shield that is extruded and coated outside the insulating shielding layer. Layer 14, in any cross-section, the center of the conductor and the insulation layer coincide, and the diameter of the insulation layer is 1.5 to 5 times the diameter of the conductor and the minimum thickness of the insulation layer is 1.5mm; the armor layer It is composed of filling rope 6 and reinforcement 7. The reinforcement 7 is composed of reinforcement member 71 and plastic cushion...

Embodiment 2

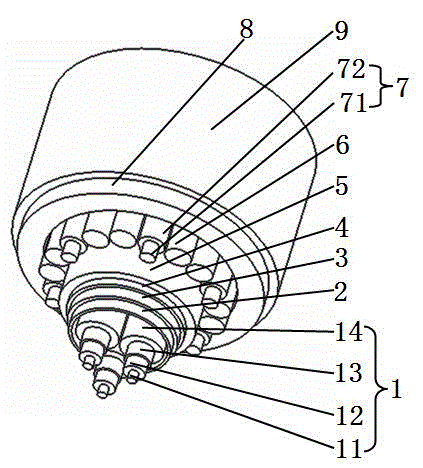

[0061] please see image 3 and Figure 4 , a submarine high-voltage cable, which is characterized in that it is composed of a metal shielding layer 2, a water blocking layer 3, an adhesive layer 4, an inner sheath 5, an armor layer, an outer sheath 8, and an outer sheath, which are sequentially arranged from the inside to the outside. The protective layer 9 is composed of three conductive units 1 arranged in two or two phases that are circumscribed inside the metal shielding layer, and the three conductive units are inscribed with the metal shielding layer; The insulating layer 12, the insulating shielding layer 13 located outside the insulating layer, and the conductor sheath 14 extruded and coated outside the insulating shielding layer, in any cross-section, the center of the conductor coincides with the center of the insulating layer , and the diameter of the insulating layer is 1.5 to 5 times the diameter of the conductor and the minimum thickness of the insulating layer ...

Embodiment 3

[0063] please see Figure 5 and Figure 6 , a submarine high-voltage cable, which is characterized in that it is composed of a metal shielding layer 2, a water blocking layer 3, an adhesive layer 4, an inner sheath 5, an armored layer, and an outer sheath 8, which are sequentially arranged from the inside to the outside. Inside the layer, there are three conductive units 1 arranged in two or two phases that are circumscribed, and the three conductive units are inscribed with the metal shielding layer; The insulating shielding layer 13 outside the insulating shielding layer and the conductor sheath 14 extruded and coated outside the insulating shielding layer are formed. In any cross-section, the center of the conductor coincides with the center of the insulating layer, and the diameter of the insulating layer is 1.5 to 5 times the diameter of the conductor and the minimum thickness of the insulating layer is 1.5mm; the armor layer is composed of a filler rope 6 and a reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com