Novel low-smoke zero halogen flame-retardant cable material

A flame retardant cable and material technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem that the low temperature resistance is not very good, the physical and mechanical properties and processing performance of the cable material are affected, and the weather resistance is poor. and other problems, to achieve the effect of good weather resistance, good high pressure resistance and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

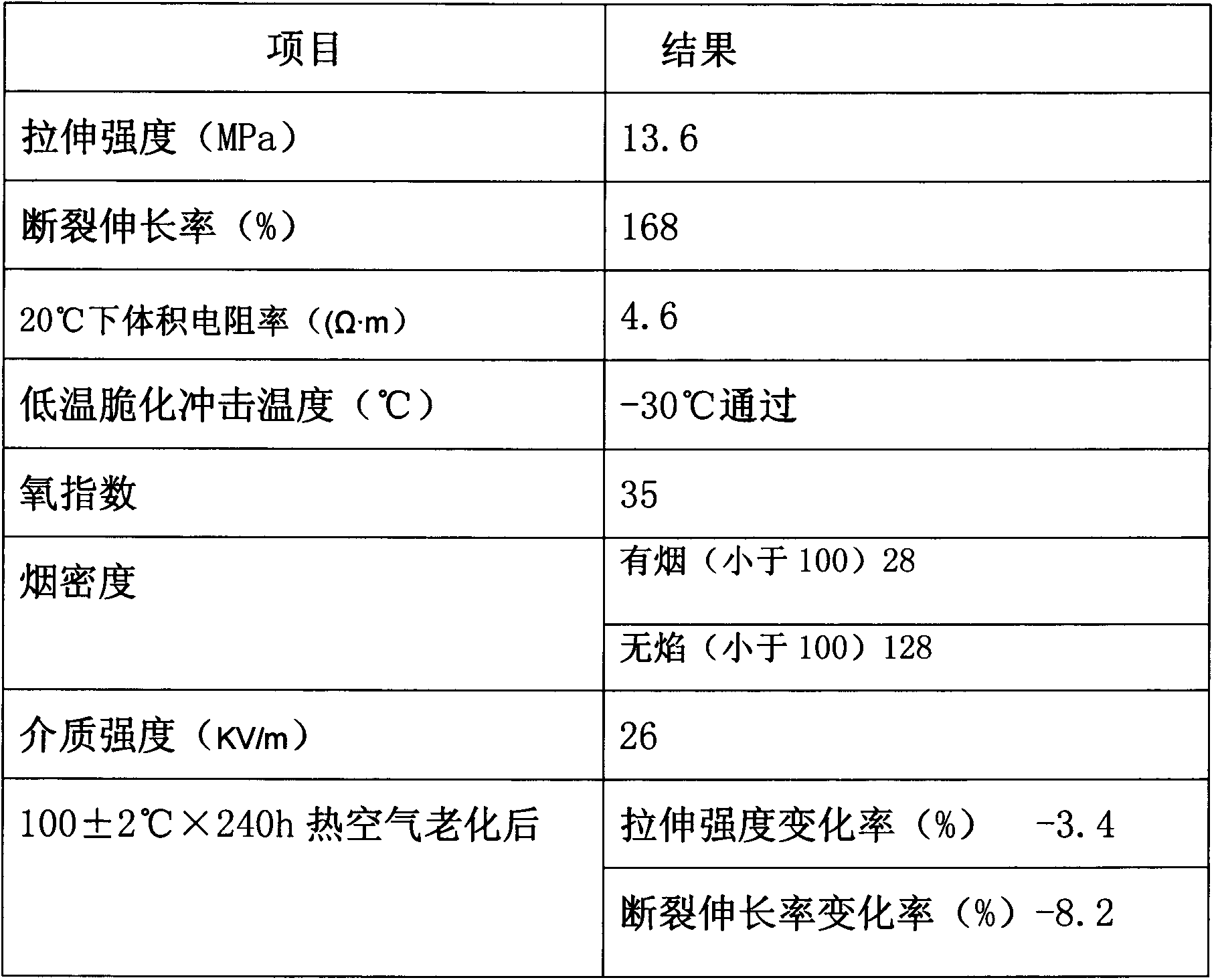

Image

Examples

Embodiment 1

[0011] Example 1, a new low-smoke halogen-free flame-retardant cable material, said material is made of the following raw materials in parts by weight, 40 parts of EVA resin, 50 parts of magnesium hydroxide flame retardant modified by silane coupling agent 5 parts of nano-silicon carbide, 0.3 parts of nano-aluminum nitride powder, 1 part of cross-linking agent, 1 part of calcium stearate, 0.5 parts of stearic acid, 0.3 parts of ultraviolet absorber UV~531, 12 parts of smoke suppressant, 30 parts of compatibilizer, 3 parts of antioxidant, 8 parts of processing aid, 4 parts of antioxidant, 2 parts of anti-termite agent, described anti-termite agent, is made up of following components by weight: Abamectin 60-80 parts, 6-12 parts of asarin and 6-12 parts of dihydrocapsaicin; the processing aids are paraffin and stearic acid. The raw materials are mixed on a mixer, plasticized and granulated on a screw extruder, and the halogen-free flame-retardant cable material of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com