High-voltage lithium ion battery electrolyte

A lithium-ion battery and electrolyte technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of deterioration of battery high-temperature cycle performance, improve high-temperature performance and cycle performance, solve severe gas swelling, and suppress side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

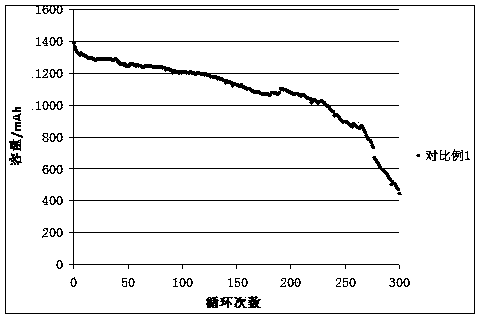

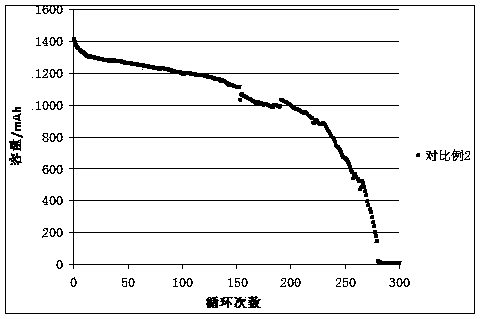

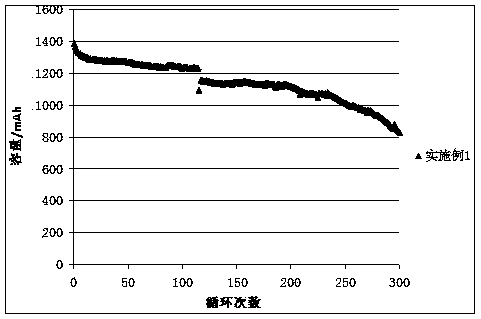

Image

Examples

Embodiment 1

[0044] In an argon-filled glove box (moisture 2 HCF 2 CH 2 OCF 2 CF 2 H, adiponitrile, vinylene carbonate, CF 2 HCF 2 CH 2 OCF 2 CF 2 H, the addition of adiponitrile accounts for 1.0%, 3.0%, and 3.0% of the total mass respectively; finally, slowly add lithium hexafluorophosphate, which accounts for 13.5% of the total mass, to the mixed solution, and stir well to obtain the high-voltage lithium of Example 1 of the present invention Ion battery electrolyte.

Embodiment 2

[0046] In a glove box filled with argon (moisture 2 HCF 2 CH 2 OCF 2 CF 2 H, adiponitrile, vinylene carbonate, CF 2 HCF 2 CH 2 OCF 2 CF 2 H, the addition of adiponitrile accounted for 1.0%, 2.0%, 3.0% of the mass respectively; finally, slowly added lithium hexafluorophosphate accounting for 13.5% of the total mass into the mixed solution, and stirred evenly to obtain the high-voltage lithium lithium phosphate of Example 2 of the present invention Ion battery electrolyte.

Embodiment 3

[0048] In a glove box filled with argon (moisture 2 HCF 2 CH 2 OCF 2 CF 2 H, adiponitrile, vinylene carbonate, CF 2 HCF 2 CH 2 OCF 2 CF 2 H, the addition of adiponitrile accounts for 1.0%, 3.0%, and 2.0% of the mass respectively; finally, slowly add lithium hexafluorophosphate accounting for 13.5% of the total mass to the mixed solution, and stir well to obtain the high-voltage lithium phosphate of Example 3 of the present invention Ion battery electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com