Method for rapidly dissolving copper

A copper-dissolving and fast technology, applied in the direction of copper sulfate, etc., can solve the problems of low production efficiency, low oxidation potential, slow copper dissolution speed, etc., and achieve the effect of reduced evaporation, high oxidation potential and increased charging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

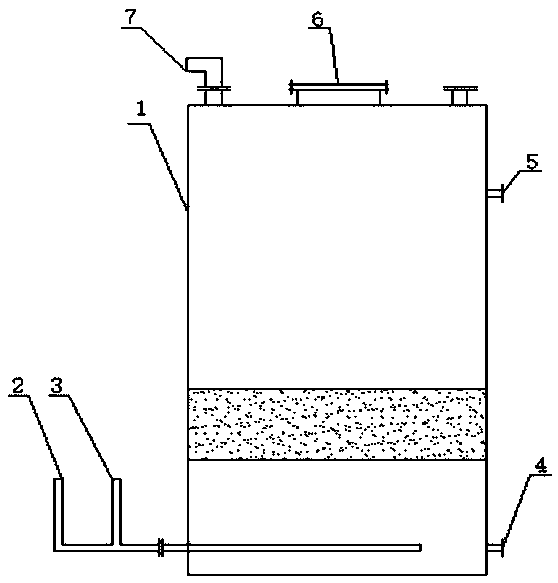

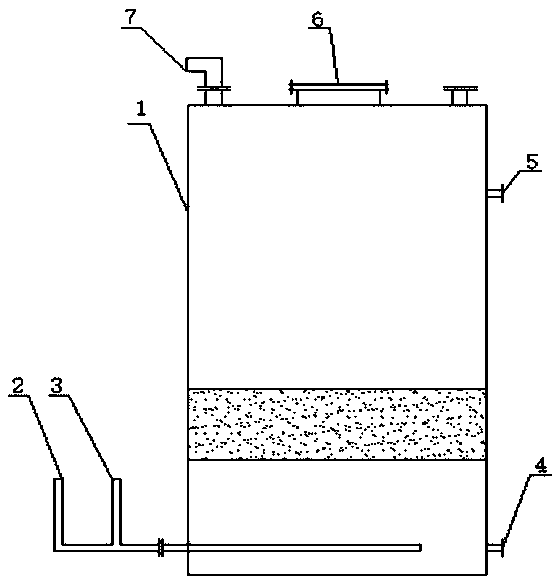

Image

Examples

Embodiment 1

[0029] A method for rapidly dissolving copper, the steps are as follows:

[0030] (1) Cut the cathode copper or scrap copper into 100×100mm blocks, add it to the copper melting tank (copper melting tank φ2500×4000mm), add about 5 tons of copper, and the thickness of the material layer is about 1.0m, and then close the feeding port ;

[0031] (2) Turn on the circulation pump and add the solution to the copper-dissolving tank. The components of the solution are sulfuric acid, water and copper sulfate solution. The concentration of sulfuric acid is about 85g / L, and the concentration of Cu 2+ The concentration is about 10g / L, and the solution volume is 15m 3 ;

[0032] (3) Turn on the heating equipment and heat the solution to 50-60°C;

[0033] (4) Pass compressed air into the copper melting tank, the compressed air flow rate is 100m 3 / h, pressure: 0.25Mpa;

[0034] (5) Feed SO into the compressed air 2 , flow 4.5m 3 / h, pressure: 0.25Mpa;

[0035] (6) Dissolve for about ...

Embodiment 2

[0038] A method for rapidly dissolving copper, the steps are as follows:

[0039] (1) Add the copper wire to the copper melting tank, the diameter of the copper wire is φ1mm, the length is 600mm, the copper melting tank is φ2500×4000mm, the amount of addition is about 5 tons, the thickness of the material layer is about 1.5m, and then the feeding port is closed;

[0040] (2) Turn on the circulation pump and add the solution to the copper-dissolving tank. The components of the solution are sulfuric acid, water and copper sulfate solution. The concentration of sulfuric acid is about 85g / L, and the concentration of Cu 2+ The concentration is about 10g / L, and the solution volume is 14.5m 3 , replenish in time when the concentration of sulfuric acid in the solution is lower than 20g / L;

[0041] (3) Turn on the heating equipment, heat the solution to 50-60°C, and then stop heating;

[0042] (4) Pass compressed air into the copper melting tank, the compressed air flow rate is 120m ...

Embodiment 3

[0047] A method for rapidly dissolving copper, the steps are as follows:

[0048] (1) Add copper powder to the copper melting tank, powder D 50 70-100υm, the copper melting tank φ2500×4000mm, the amount added is about 3.5 tons, the thickness of the material layer is about 0.35m, and then the feeding port is closed;

[0049] (2) Turn on the circulation pump and add the solution to the copper-dissolving tank. The components of the solution are sulfuric acid, water and copper sulfate solution. The concentration of sulfuric acid is about 85g / L, and the concentration of Cu 2+ The concentration is about 10g / L, and the solution volume is 15.5m 3 , replenish in time when the concentration of sulfuric acid in the solution is lower than 20g / L;

[0050] (3) Turn on the heating equipment, heat the solution to 50-60°C, and then stop heating;

[0051] (4) Pass compressed air into the copper melting tank, the compressed air flow rate is 125m 3 / h, pressure: 0.25Mpa;

[0052] (5) Feed SO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com