Method for recovering multiple valuable substances from waste diamond tool bit raw materials

A diamond cutter head and raw material technology, applied in the field of waste cemented carbide recycling, can solve the problems of poor process adaptability, large equipment investment, irregular shape, etc., and achieve the effects of increased oxidation leaching speed, high degree of automation, and increased oxidation potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

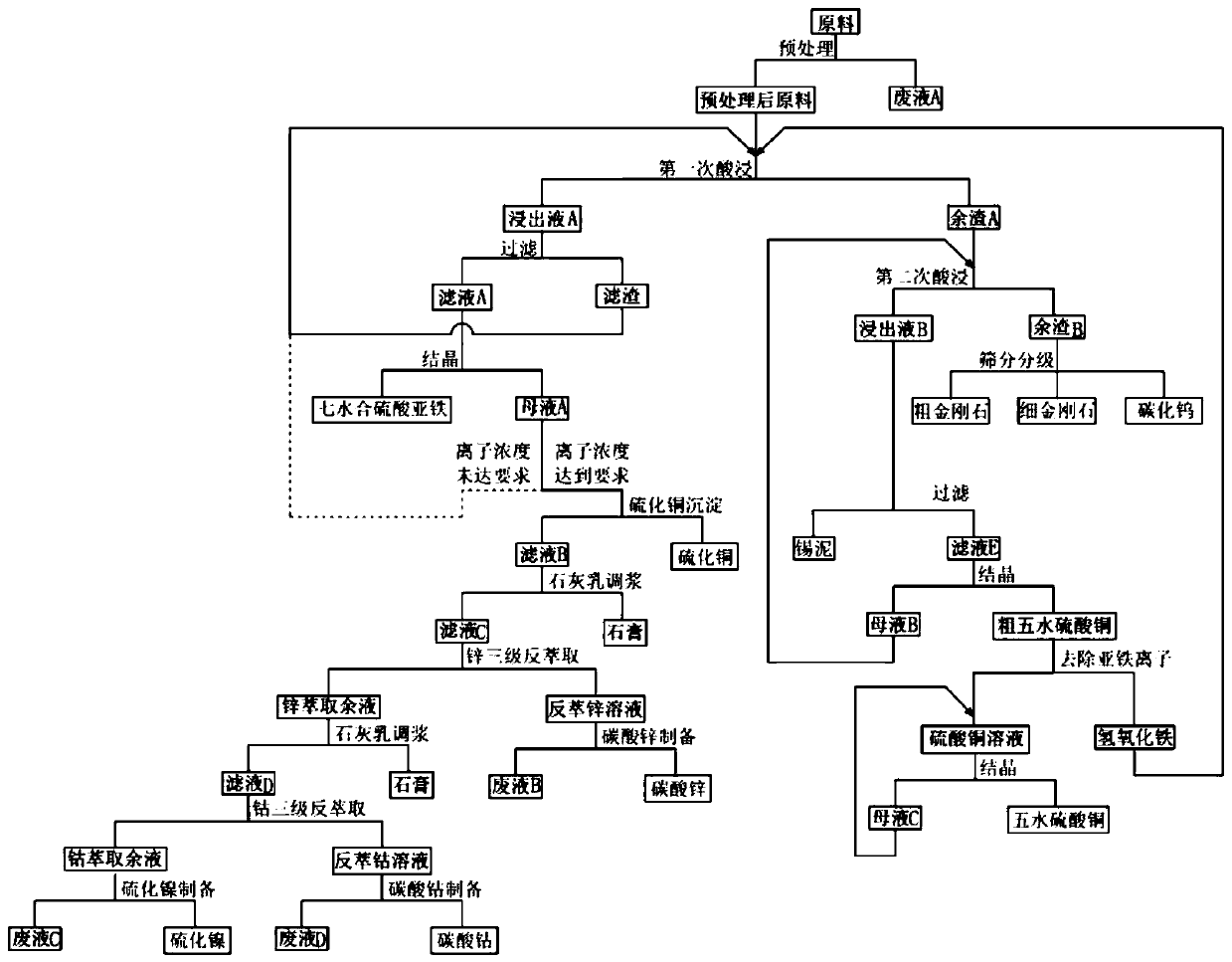

[0030] Example 1: See figure 1 , the present invention provides a technical solution: a method for recovering multiple valuable substances from waste diamond cutter head raw materials, which includes the following steps:

[0031] S1. Raw material pretreatment: Under normal temperature and pressure, use a sodium hydroxide solution with a concentration of about 50g / L in a rotary washing machine to pretreat the waste diamond segment raw material to remove impurities such as sediment and grease on the surface of the raw material. After the raw materials are cleaned, they pass through a sieving machine with a sieve hole of 4mm. The products on the screen enter the rotary rinse liquid tank and are rinsed with clean water. After rinsing, the raw materials enter the acid leaching reactor for the first acid leaching.

[0032] S2, the first acid leaching: the first acid leaching is carried out on the raw materials treated in S1, the liquid-solid mass ratio is 2.5-3:1, so that relatively...

Embodiment 2

[0046] Embodiment 2: collect the waste diamond cutter head raw material from the main granite production areas in the country, and find after analysis that the main valuable substances in the waste diamond cutter head raw material include diamond, tungsten carbide and copper, cobalt, nickel, zinc, iron, tin and other elements. Through a large number of exploratory tests, a process for recovering the above-mentioned valuable substances is proposed, and then the feasibility of the process is verified through small-scale laboratory tests, and then industrial tests are carried out.

[0047] Semi-industrial test:

[0048] Chemical analysis was carried out on the waste diamond cutter head raw materials, and the contents of the main valuable substances are shown in Table 1 below.

[0049] Table 1 The content of the main valuable substances in the waste diamond cutter head raw materials used in the semi-industrial test

[0050] components Fe Cu Ni co Zn diamond...

Embodiment 3

[0073] Industrial test:

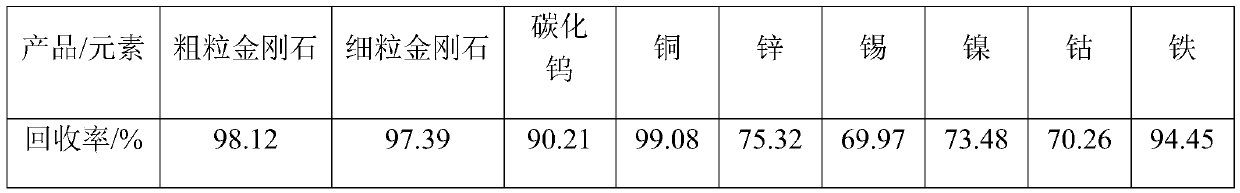

[0074] The industrial test was carried out with 10 tons of waste diamond cutter head raw materials. The contents of the main valuable substances in the raw materials are shown in Table 3 below, and the experimental results are listed in Table 4.

[0075] Table 3 The content of the main valuable substances in the waste diamond cutter head raw materials used in industrial tests

[0076] components Fe Cu Ni co Zn diamond Tungsten carbide mn Cr sn other content / % 35.71 38.52 2.86 0.01 4.56 2.93 13.48 0.33 0.02 1.27 0.31

[0077] Table 4 Industrial test indicators

[0078]

[0079] The industrial test results show that the method of the present invention is successfully industrialized and has achieved results similar to the semi-industrial test. The process described in this method can efficiently reclaim the main valuable substances in the waste diamond cutter head raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com