650V-700V extra-high-voltage aluminum electrolytic capacitor, working electrolyte and preparation method thereof

An aluminum electrolytic capacitor and ultra-high voltage technology, applied in the field of electrolyte, can solve the problems of ineffective high-voltage resistance performance, achieve low gas production performance, and improve the effect of high-voltage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

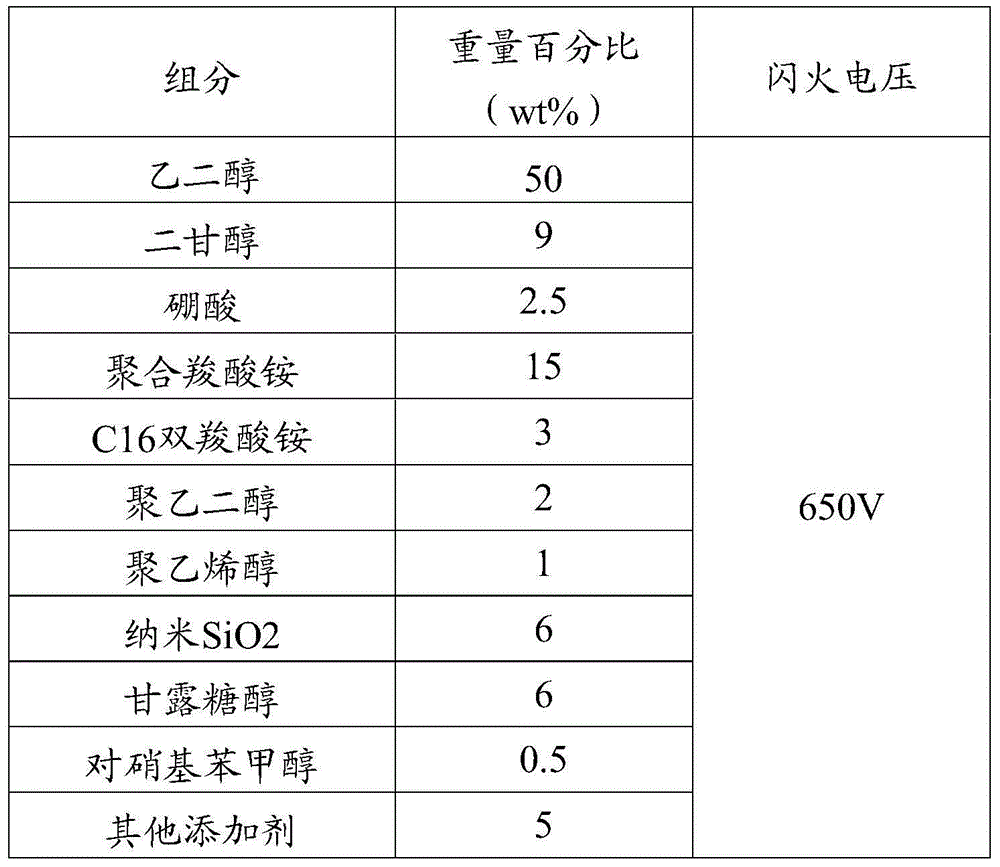

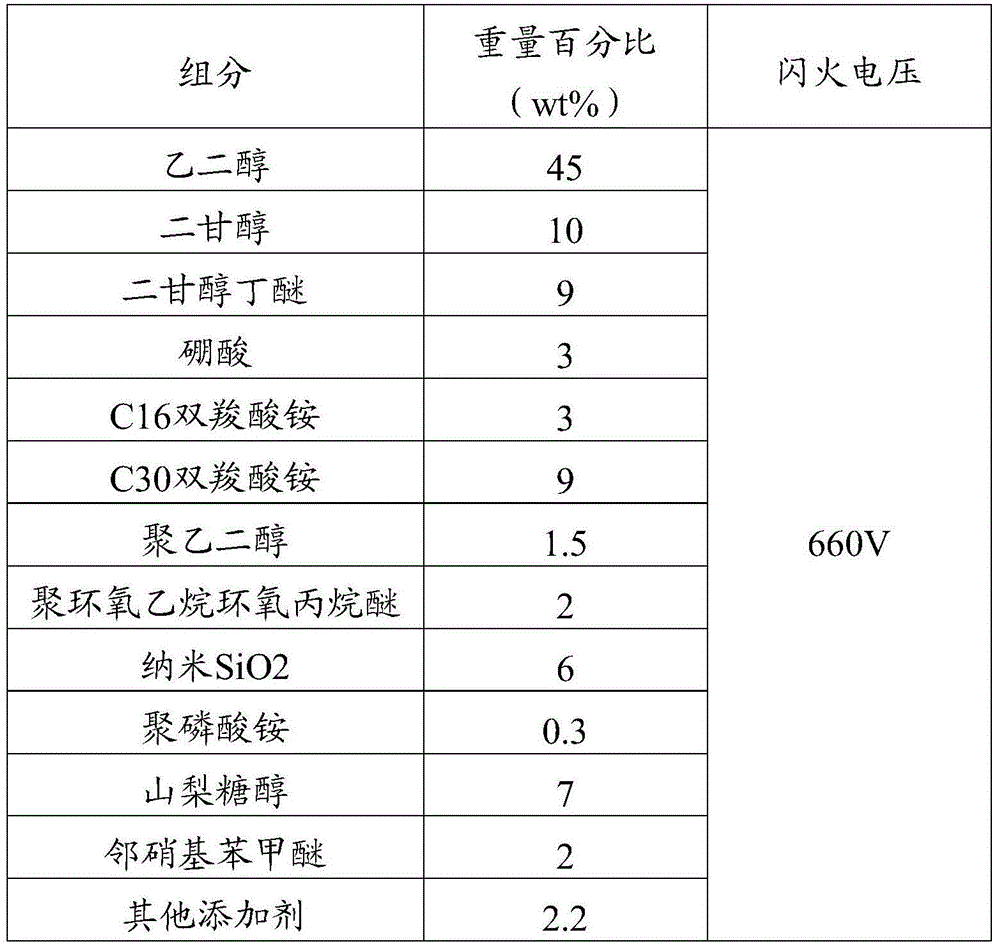

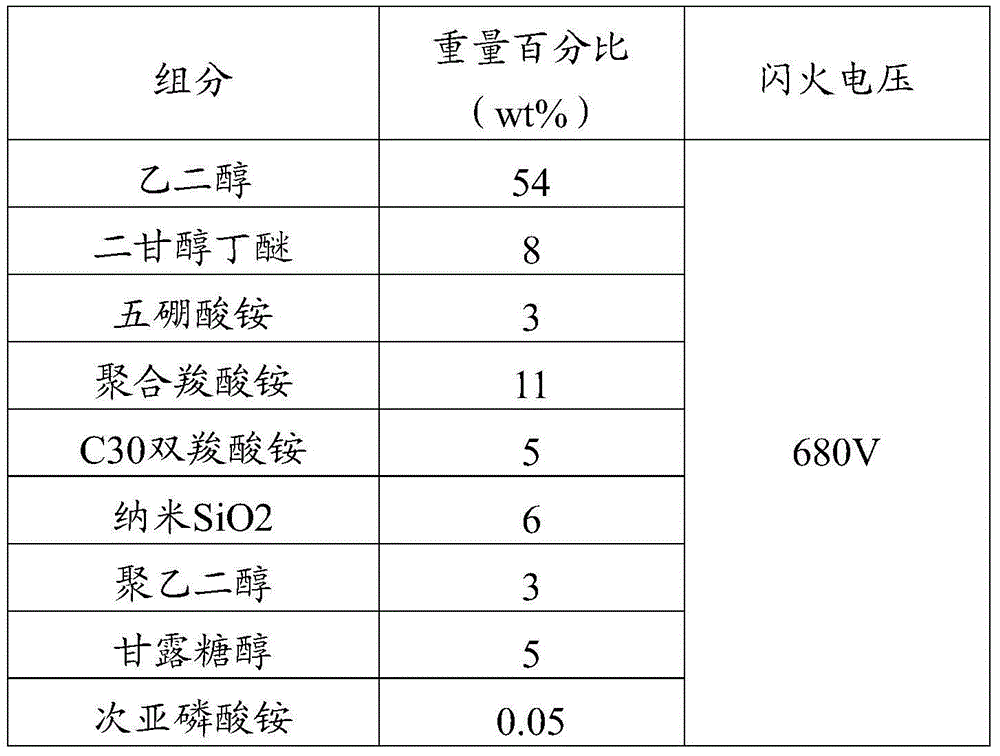

Examples

preparation example Construction

[0087] The present invention further provides a method for preparing the working electrolyte of a 650V-700V ultra-high voltage aluminum electrolytic capacitor, comprising:

[0088] Fully mix the main solvent with a weight percentage of 45-65% and the auxiliary solvent with 5-20%, and heat to 60-90°C;

[0089] Add 0.5-2.5% by weight of the flash voltage enhancer (the flash voltage enhancer added here does not contain nano-SiO2), and after fully stirring, heat to 140-155°C;

[0090] After cooling the above mixed solution to 120°C through circulating water, add 10-20% solute by weight, stir and mix evenly, then add stabilizer with 6-10% by weight, and then heat to 110-130°C; In the present invention, if the flash voltage increasing agent contains nano-SiO2, the nano-SiO2 needs to be added here, and as a preference, add nano-SiO2 after cooling the above mixed solution to 90 degrees;

[0091] Finally, 0.2-3% by weight of hydrogen absorbent and 2-5% by weight of other additives are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com