125 DEG C high temperature long life aluminum electrolysis capacitor, production method thereof and special electrolysis liquid

An aluminum electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve problems such as anode corrosion and achieve the effect of high ripple current resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

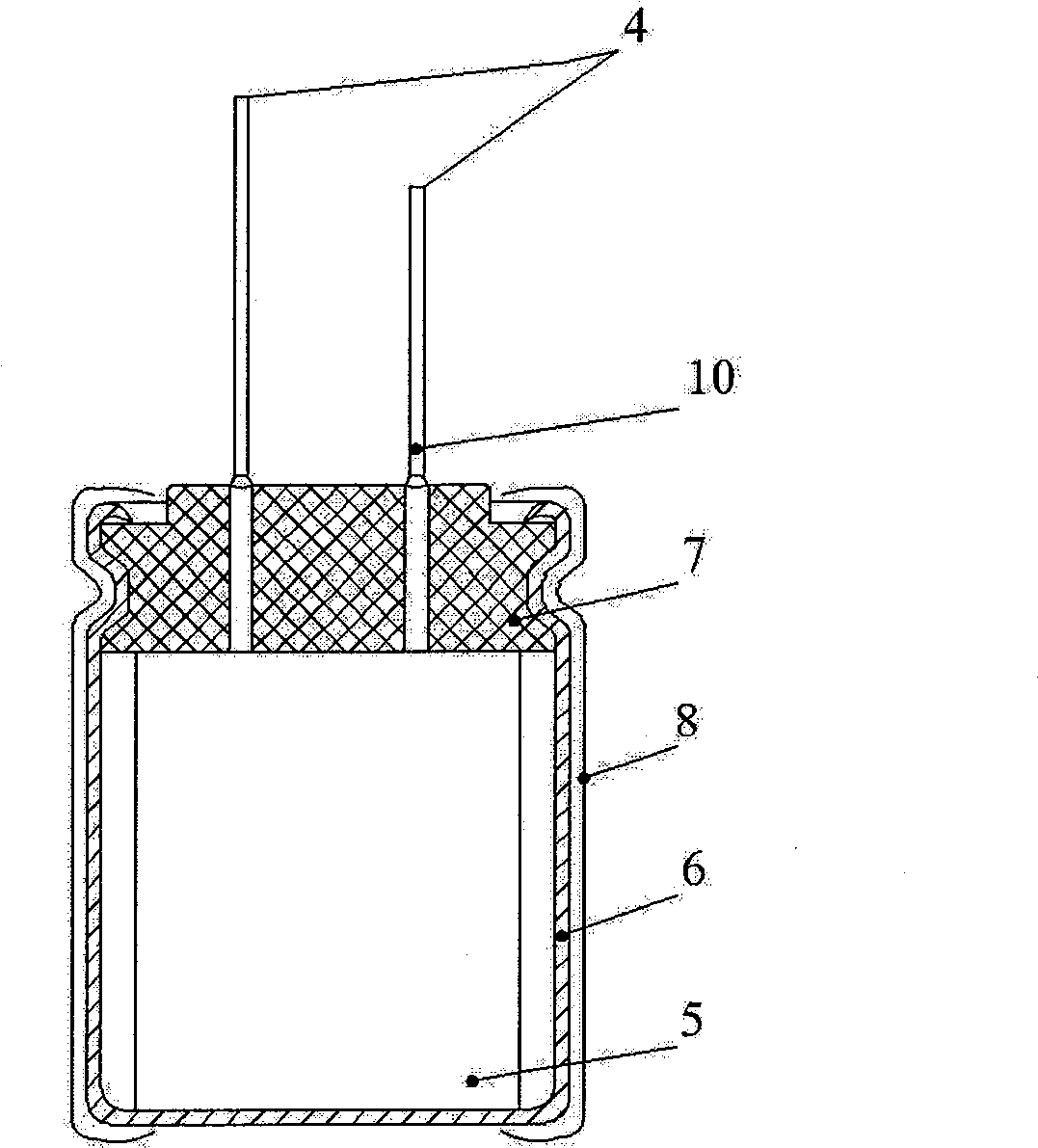

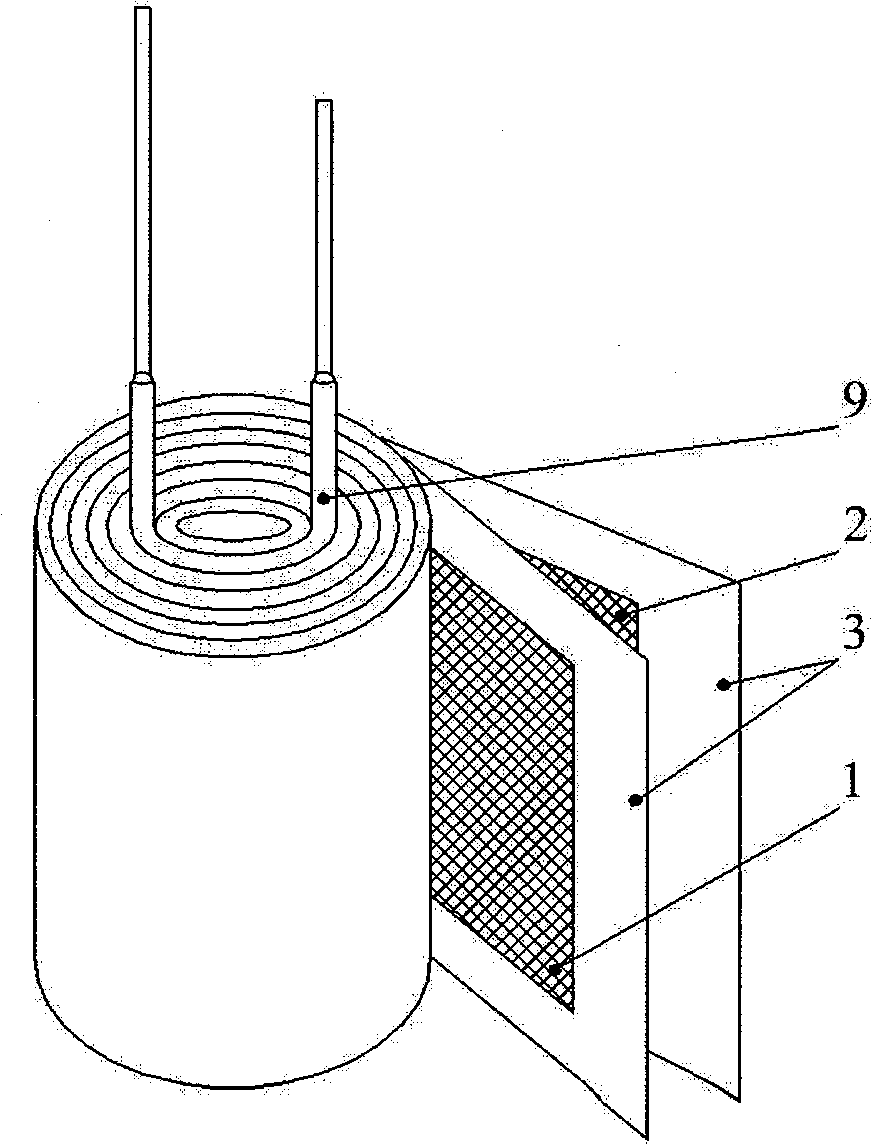

[0027] Example 1 Aluminum electrolytic capacitor 250V 68μF, 16 x 30.

[0028] The electrolyte solution of formula 1 is used in this embodiment.

[0029] The forming voltage of the aluminum tongue and the aluminum stalk of the positive lead wire used is 300V, and the aluminum purity is 99.97%.

[0030] The rubber stopper used is EPMD with a hardness of 72IRHD and an overall chlorine content of 60PPM.

[0031] Table 3 is the data of the durability test. The test condition is 125°C, the working voltage with ripple current is applied, the ripple current is 227mA / 100HZ, and the test time is 5000 hours.

[0032] Table 3. 250V68μF, 16x30 125℃ durability test data

[0033] time (h) 0 1000 2000 3000 4000 5000 Capacitance C

Embodiment 2

[0034] Example 2 Aluminum electrolytic capacitor 450V 33μF, 16x30.

[0035] The electrolyte solution of formula 2 is used in this embodiment.

[0036] The forming voltage of the aluminum tongue and the aluminum stalk of the positive lead wire used is 600V, and the aluminum purity is 99.97%.

[0037] The rubber stopper used is EPMD with a hardness of 83IRHD and an overall chlorine content of 60PPM.

[0038] Table 4 is the data of the durability test. The test conditions are 125°C, a working voltage with ripple current is applied, the ripple current is 158mA / 100HZ, and the test time is 5000 hours.

[0039] Table 4. 450V33μF, 16x30 125℃ durability test data

[0040] time (h) 0 1000 2000 3000 4000 5000 Capacitance C(μF) 30.85 30.47 29.54 28.75 28.01 26.32 Capacity change rate

[0041] After the example product passed the durability test at 125°C for 5000 hours, the electrical parameters were excellent and the appearance was good. No anode corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com