Aluminum electrolysis carbon anode oxidation coating and coating method thereof

An anti-oxidation coating and carbon anode technology, applied in the field of aluminum electrolytic carbon anode anti-oxidation coating and its coating, can solve problems such as shedding, economic problems, and no industrial application, and achieve enhanced anti-oxidation ability and good moisturizing effect. wet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

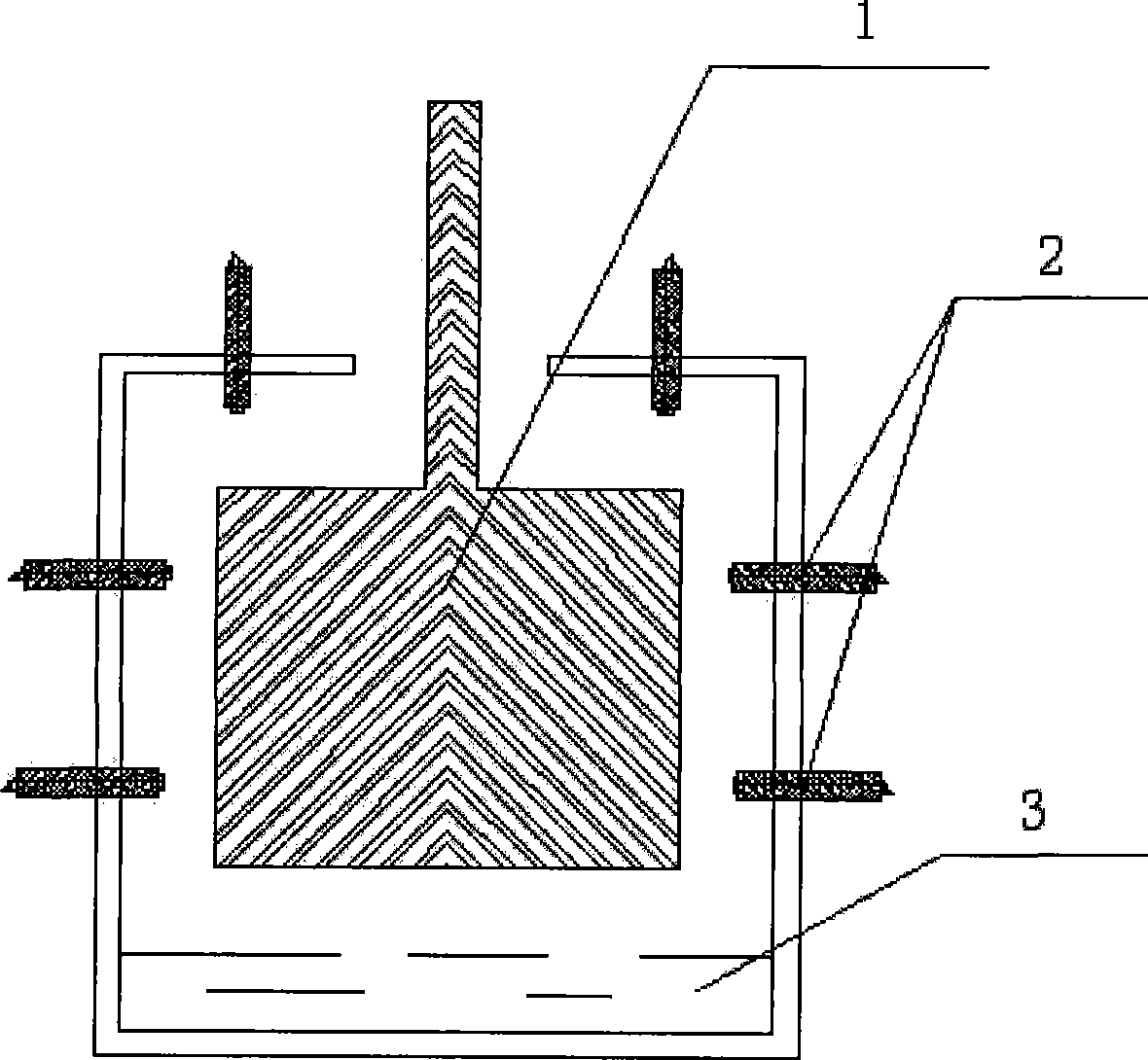

Image

Examples

Embodiment 1

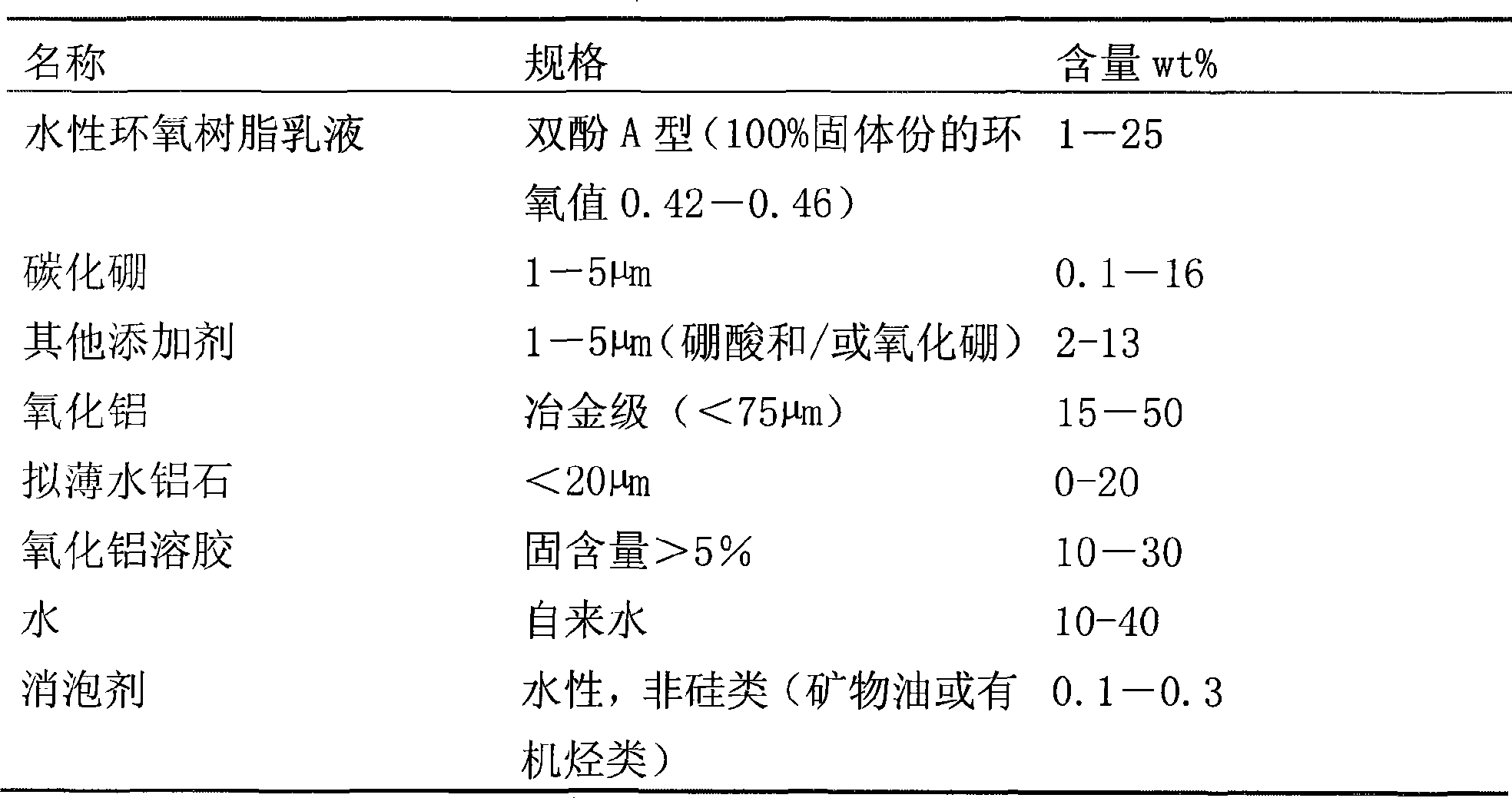

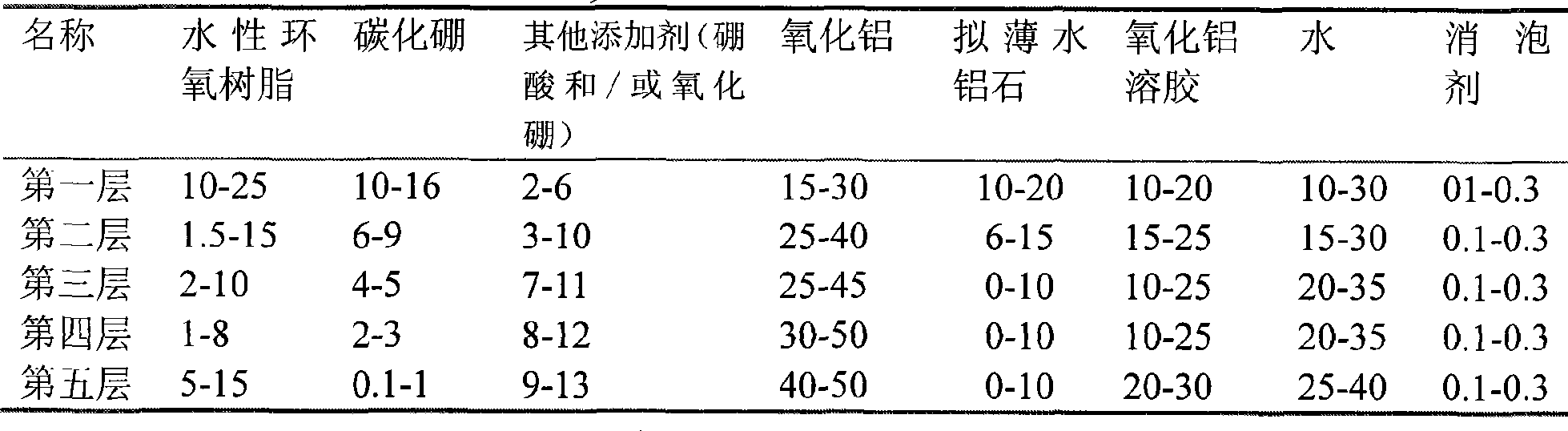

[0035] Embodiment 1 (three-layer structure)

[0036] 1) Preparation of the first layer of coating: 27.6wt% water, 20.7wt% bisphenol A water-based epoxy resin, 15wt% boron carbide, 2.2wt% boric acid, 24.1wt% alumina, 10.3wt% solid content greater than 5wt % alumina sol and 0.1wt% DF568 defoamer, mixed uniformly at room temperature to prepare coating slurry;

[0037] 2) Preparation of the second layer of coating: 28.0wt% water, 8.8wt% bisphenol A water-based epoxy resin, 9wt% boron carbide, 6wt% boric acid, 26.8wt% alumina, 6.3wt% pseudoboehmite 15wt% alumina sol with a solid content greater than 5wt% and 0.1wt% DF568 defoamer, mixed uniformly at room temperature to prepare a coating slurry;

[0038] 3) Preparation of the third layer of coating: 22.0wt% water, 3.7wt% bisphenol A water-based epoxy resin, 4.5wt% boron carbide, 7.4wt% boron oxide, 44.8wt% aluminum oxide, 17.5wt% solid content More than 5wt% alumina sol and 0.1wt% DF568 defoamer are mixed uniformly at room tempera...

Embodiment 2

[0042] Embodiment 2: (four-layer structure)

[0043] 1) Preparation of the first layer of coating: 29.4wt% water, 20.4wt% bisphenol A waterborne epoxy resin, 14.7wt% boron carbide, 5.9wt% boron oxide, 17.6wt% aluminum oxide, 11.9wt% are 5wt% alumina sol and 0.1wt% DF558 defoamer were mixed uniformly at room temperature to prepare a coating slurry;

[0044] 2) Preparation of the second layer of coating: 25.0wt% water, 12.5wt% bisphenol A water-based epoxy resin, 8.0wt% boron carbide, 26.4wt% aluminum oxide, 5.0wt% boron oxide, 7.5wt% quasi-thin diaspore, 15.5wt% alumina sol with a solid content of 5wt%, and 0.1wt% DF558 defoamer were uniformly mixed at room temperature to prepare a coating slurry;

[0045] 3) Preparation of the third layer of coating: 33.0wt% water, 10.0wt% bisphenol A water-based epoxy resin, 5.0wt% boron carbide, 8.0wt% boron oxide, 28.0wt% aluminum oxide, 5.9wt% quasi-thin diaspore, 10.0wt% alumina sol with a solid content of 5wt% and 0.1wt% DF558 defoamer...

Embodiment 3

[0050] Embodiment 3 (five-layer structure)

[0051] 1) Preparation of the first layer of coating: 20.5wt% water, 11.6wt% bisphenol A water-based epoxy resin, 16.0wt% boron carbide, 4.0wt% boron oxide, 2wt% boric acid, 28.8wt% aluminum oxide, 17.0 Alumina sol with a solid content of 5wt% and 0.1wt% CLT-371 defoamer were mixed uniformly at room temperature to prepare a coating slurry;

[0052] 2) Preparation of the second layer of coating: 20.4wt% water, 11.6wt% bisphenol A water-based epoxy resin, 7.0wt% boron carbide, 31.0wt% aluminum oxide, 3.4wt% boric acid, 9.5wt% pseudo thin water Bauxite, 17.0wt% alumina sol with a solid content of 5wt% and 0.1wt% CLT-371 defoamer were uniformly mixed at room temperature to prepare a coating slurry;

[0053] 3) Preparation of the third layer of coating: 20.4wt% water, 9.0wt% bisphenol A water-based epoxy resin, 4.4wt% boron carbide, 6.5wt% boron oxide, 4.5wt% boric acid, 35.0wt% aluminum oxide, 3.5wt% pseudo-boehmite, 17.0wt% alumina so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com