Dynamic evolution modeling method for aluminum electrolysis process electrolytic bath technology energy consumption

A technology of process energy consumption and dynamic evolution, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as slow algorithm convergence speed, lack of self-adaptive ability, and filter gain that cannot be adjusted online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0068] The structure of the novel aluminum electrolytic cell of an aluminum factory in the embodiment of the present invention is as follows: figure 1 shown. The dynamic evolution modeling method of the electrolytic cell process energy consumption in the aluminum electrolysis process of the present invention specifically includes the following steps:

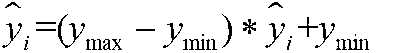

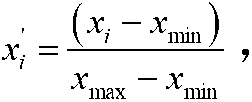

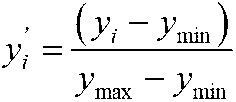

[0069] Step 1: Measure and collect process parameters of No. 225 aluminum electrolytic cell of an aluminum plant: series current (A), molecular ratio (1), aluminum level (cm), electrolyte level (cm), bath temperature (°C), output Aluminum content (kg), fluoride salt daily consumption (kg), cutting interval (s), tank voltage (mv) these 9 decision-making parameters and energy consumption index DC power consumption value, the obtained data is [X 130 ,Y], where: 130 is the sample number of collected data, Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com