High-temperature disposal method for spent cathodes of electrolytic aluminum

A disposal method, electrolytic aluminum technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as ineffective recovery of fluoride by combustion method, waste of resources, environmental pollution of electrolytic aluminum waste cathodes, etc. Achieve the effect of harmless disposal and resource utilization, and increase the fixed carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

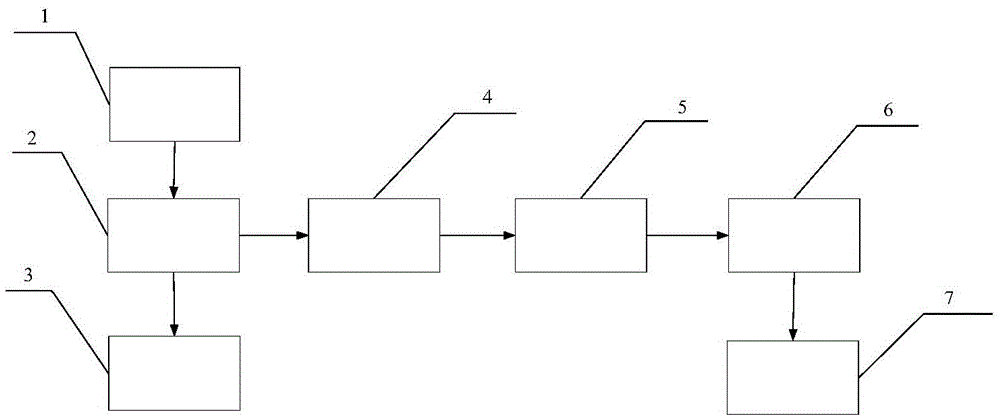

[0019] see figure 1 1 in the figure is a 3-15mm electrolytic aluminum waste cathode carbon block, which is added to a high-temperature furnace 2 whose temperature can reach 2600-2800°C, and is discharged from the high-temperature furnace after more than 1 hour of high-temperature roasting and cooling to form high-purity carbon. The raw material 3, the fluoride volatilized in the high-temperature furnace passes through the water mist absorption device 4, and then passes through the filtering device 5 and the drying device 6 to finally form the fluoride electrolyte 7. In this embodiment, the electrolytic aluminum waste cathode carbon blocks are broken to 3-15 mm, and then roasted by ultra-high temperature equipment to volatilize the fluoride and the like in it, the cyanide is decomposed, and the fluoride and the like are absorbed by water mist absorption.

[0020] Broken electrolytic aluminum waste cathode carbon block to 3-15mm, and then put it into a high-temperature furnace w...

Embodiment 2

[0023] Broken electrolytic aluminum waste cathode carbon blocks to 10-15mm, and then put them into a high-temperature furnace with a temperature of 2700°C, roasted for 1.5 hours, and the smoke was absorbed by water mist, then filtered and dried, and the carbon was discharged after cooling. Furnace, in which the fixed carbon content reaches 97%, the yield is 80%, and the particle size is 10-15mm. Other operations are the same as in Example 1.

[0024] After the water mist is absorbed, it undergoes processes such as filtration and drying to obtain fluoride, the fluoride content is about 90%, and the yield is about 30%.

Embodiment 3

[0026] Broken electrolytic aluminum waste cathode carbon blocks to 10-15mm, and then put them into a high-temperature furnace with a temperature of 2800°C, roasted for 1 hour, and the smoke was absorbed by water mist, then filtered and dried, and the carbon was discharged after cooling. Furnace, in which the fixed carbon content reaches 97%, the yield is 75%, and the particle size is 10-15mm. Other operations are the same as in Example 1.

[0027] After the water mist is absorbed, it undergoes processes such as filtration and drying to obtain fluoride, the fluoride content is about 90%, and the yield is about 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com