Temperature-resistant electrolyte for aluminum electrolysis and application thereof

An aluminum electrolysis and electrolyte technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve problems such as insufficient high temperature resistance, poor current resistance to stable waves, and low product stability, and achieve high flashover voltage and high temperature resistance Good performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

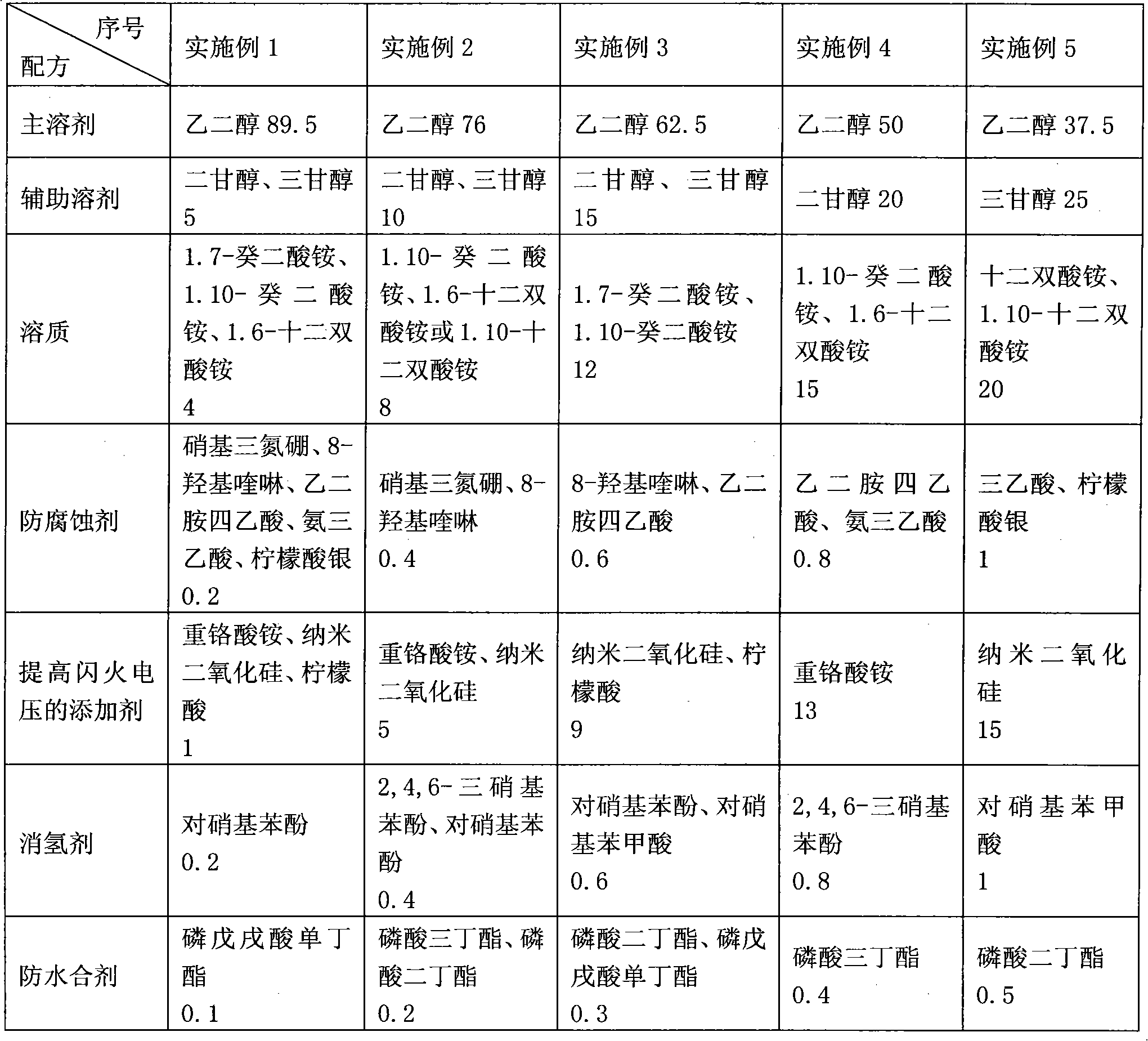

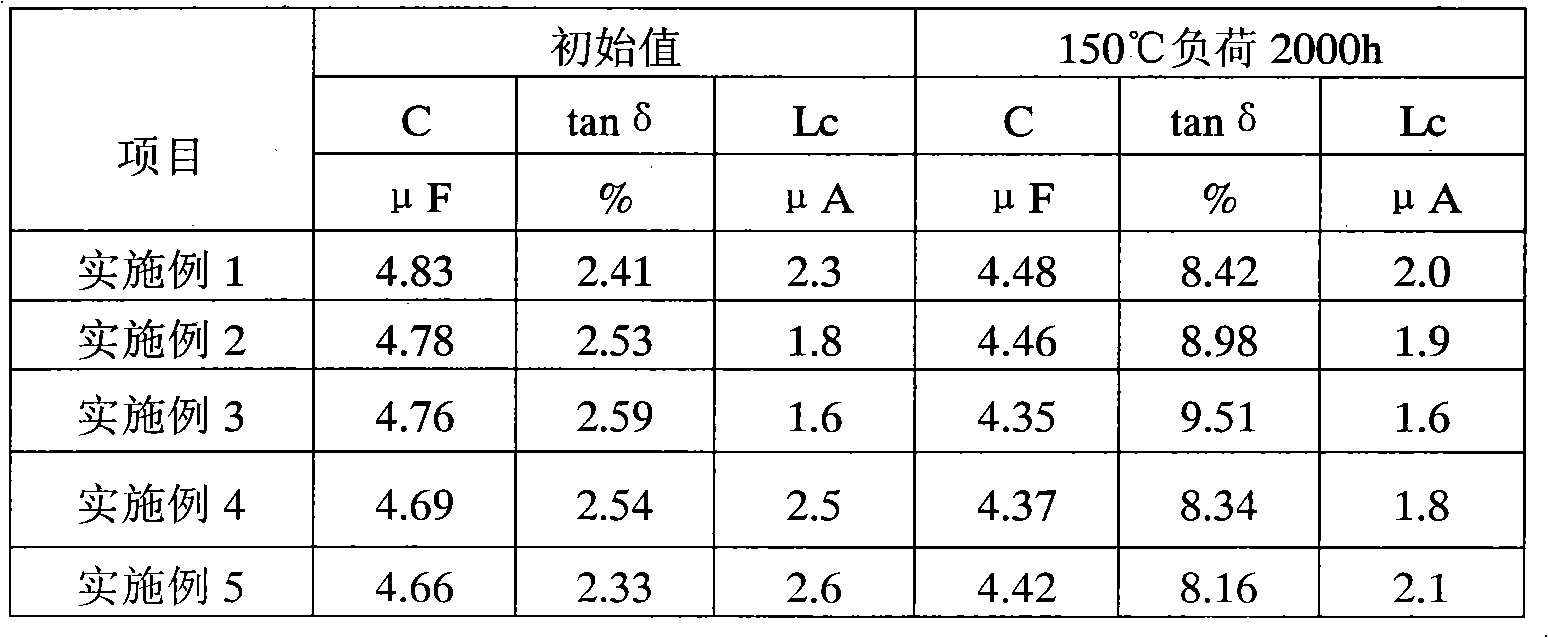

[0014] An electrolyte solution for high-temperature-resistant aluminum electrolysis, the quality of which is the formulation of the electrolyte solution No. 1-5 in the embodiment, and the formulation of the electrolyte solution No. 1-5 is formulated by using the cooking process commonly used by those skilled in the art. That is, heat the main solvent and auxiliary solvent to above 150°C, anneal and cool to 135°C, add solute, anti-corrosion agent, additive for increasing flash fire voltage, hydrogen scavenger, and water-repellent mixture to completely dissolve them, and then it can be ready after natural cooling Electrolyte No. 1-5. This group of electrolytes was used to make the electrolytes of the examples respectively to make 4.7μF / 400V Φ12.5×20 products. The high-temperature life performance of the products obtained is shown in Table 2. Test frequency / temperature: 120Hz / 25°C; test equipment It is AC and DC life test power supply and high temperature oven.

[0015] Table 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com