Pneumatic tire

a technology of pneumatic tires and tyres, which is applied in the field of pneumatic tires, can solve the problems of rust, reducing strength, and eroded cords,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

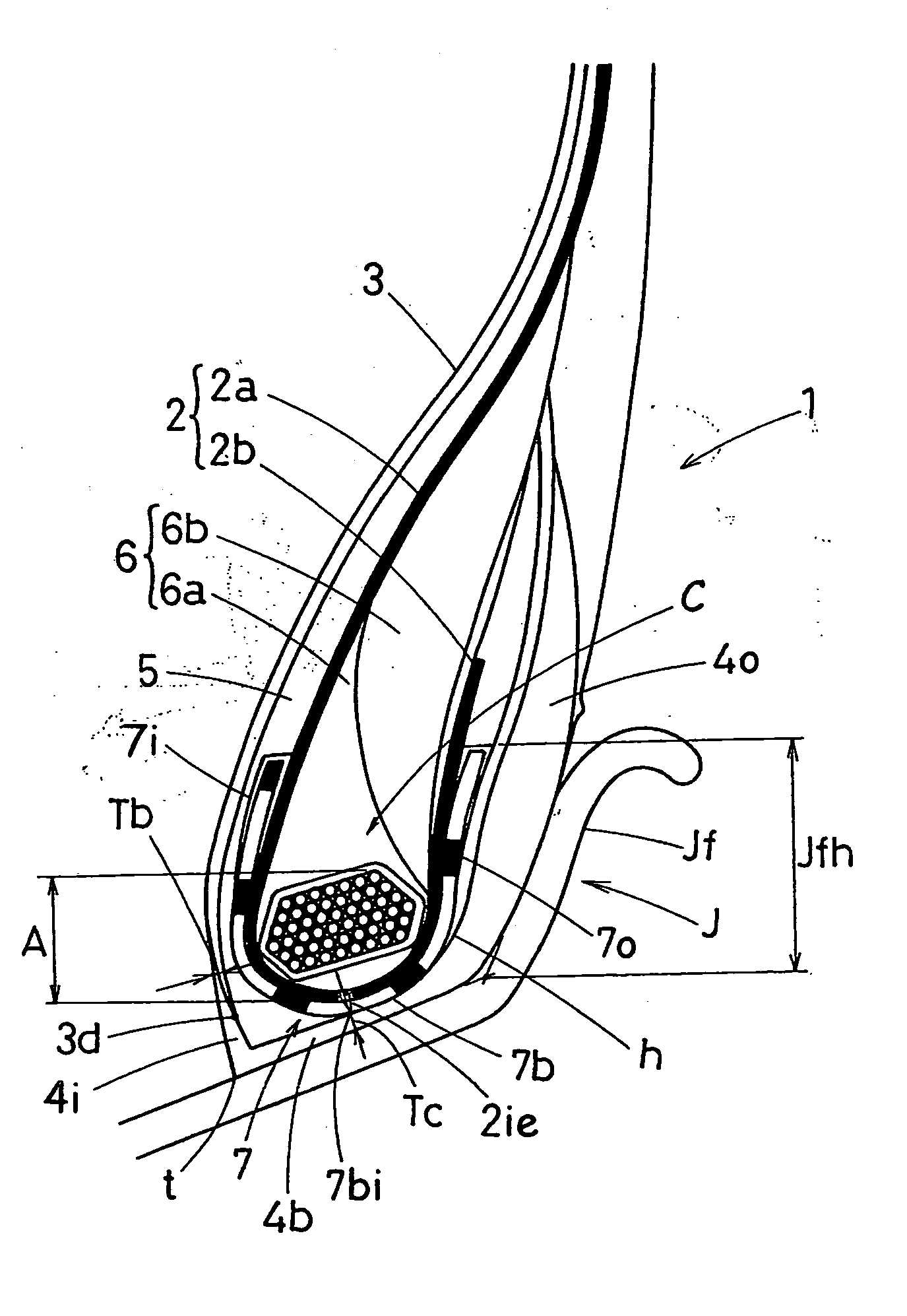

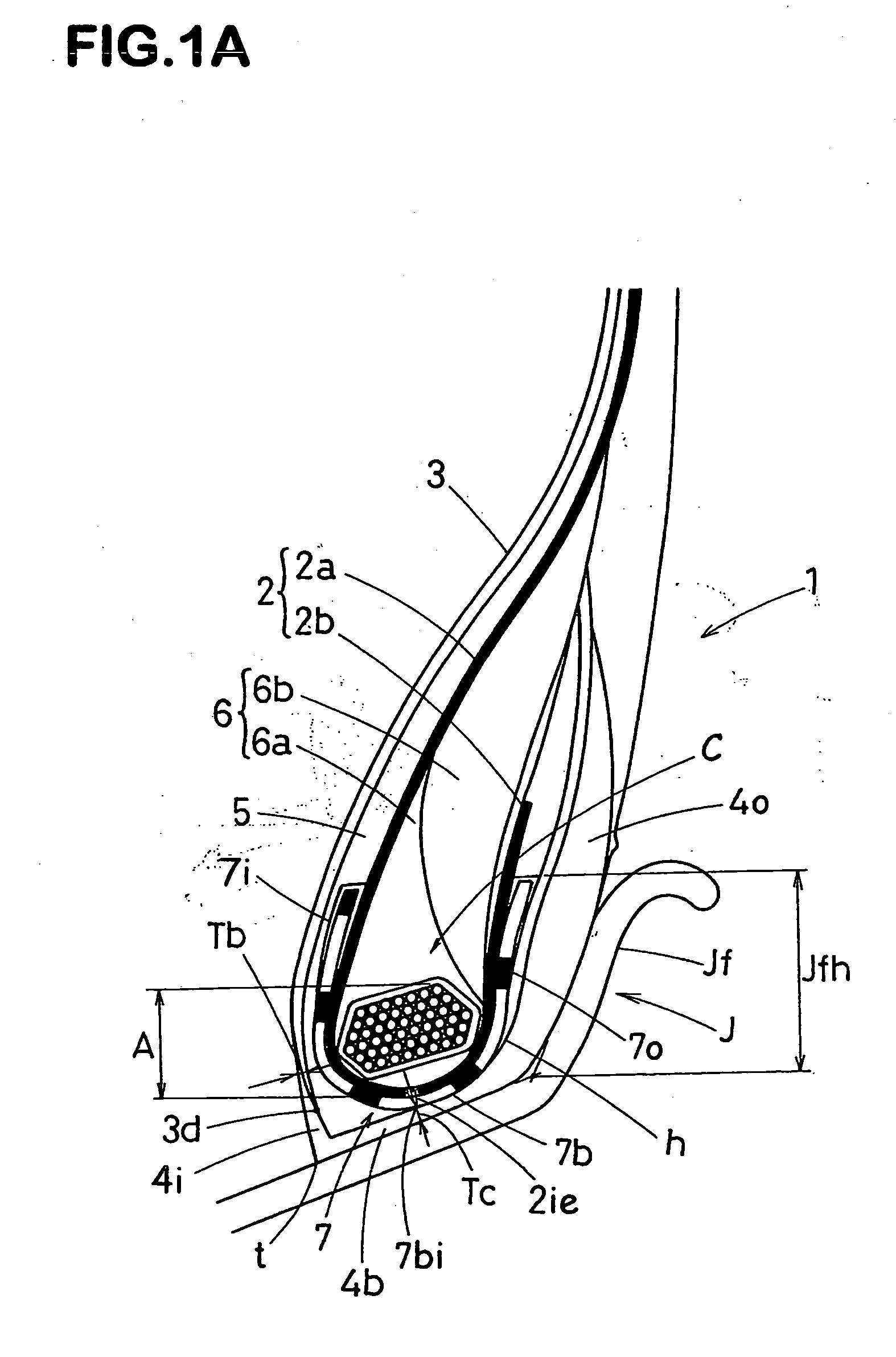

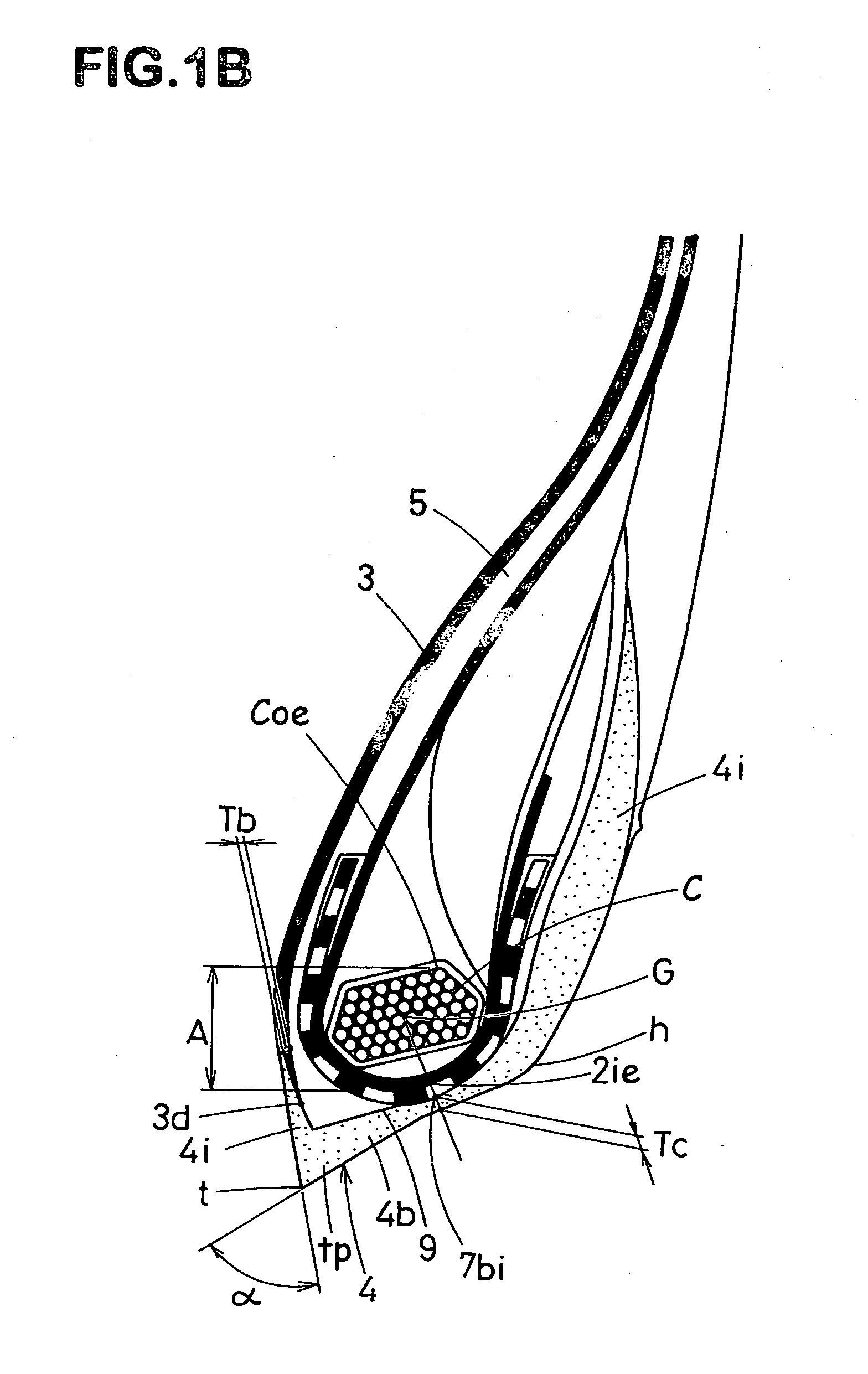

[0029]FIGS. 1A and 1B show a first embodiment of the present invention, wherein FIG. 1A shows a meridian section of the bead portion 1 in a state of the pneumatic tire which is mounted on a standard rim J and inflated to a standard inner pressure but loaded with no tire load (hereinafter the “standard state”), and FIG. 1B shows the meridian section of the bead portion 1 in a free state of the tire which is not mounted on a rim.

[0030] The bead portions 1A are each provided between the ply-main portion 2a and ply-turnup portion 2b of the carcass 2 with the bead apex 6 extending radially outwards from the upper surface of the bead core C.

[0031] The bead apex 6 in this example includes an inner apex 6a disposed adjacent to the bead core and made of a hard rubber, and an outer apex 6b disposed radially outside thereof and being softer than the inner apex.

[0032] The above-mentioned ply-turnup portion 2b is extended radially outwardly along the axially outer surface of the bead apex 6, ...

second embodiment

[0053]FIG. 2 shows a second embodiment of the present invention.

[0054] The bead apex 6 is smaller in volume and size in comparison with the above-mentioned first embodiment, and made up of an equivalent to the above-mentioned inner apex 6a alone.

[0055] The turnup portion 2b of the carcass ply extends along the axial outer surface of the bead apex 6, radially outwardly beyond the upper end 6t of the bead apex 6.

[0056] Between the carcass cords in this portion beyond the upper end 6t and the carcass cords in the carcass-ply main portion 2a, a specific cord distance CS is provided.

[0057] The cord distance Cs in this example increases from the upper end 6t of the bead apex toward the upper end 2t of the turnup-portion 2b. As to the region from the upper end 6t to the upper end 2t, in its ⅓ to ⅔ part from the upper end 6t, the cord distance CS is substantially constant, but in the remainder or radially outer part, the cord distance gradually increases. However, it may be also possibl...

third embodiment

[0062]FIG. 3 shows a third embodiment of the present invention.

[0063] In the bead portion 1, the reinforcing layer 7 having a u-shaped cross-sectional shape same as in the first embodiment is disposed along the carcass 2. The axially inner portion 7i and outer portion 70 of the reinforcing layer 7 are each extended radially outwards of the radially outermost point Coe of the bead core C up to, for example, a height corresponding to the point Coe to which a height of about 0.5 to 2.0 times that of the region (A) is added. Thus, while the carcass 2 is protected, the bending rigidity of the whole bead portion increases, a deformation of the bead portion when loaded is controlled, and strain of each part decreases. As the result, the bead durability of the tire may be improved.

[0064] The reinforcing layer 7 in this embodiment is made up of a single rubberized ply of parallel steel cords. As to the cord angle thereof, when the tire is viewed sideways facing the sidewall portion normall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com