Substrate conveyance device and vertical heat treatment equipment

A heat treatment device and substrate conveying technology, which is applied to conveyor objects, transportation and packaging, electrical components, etc., can solve the problem of reducing the accuracy of stress conveying, and achieve the effect of preventing deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

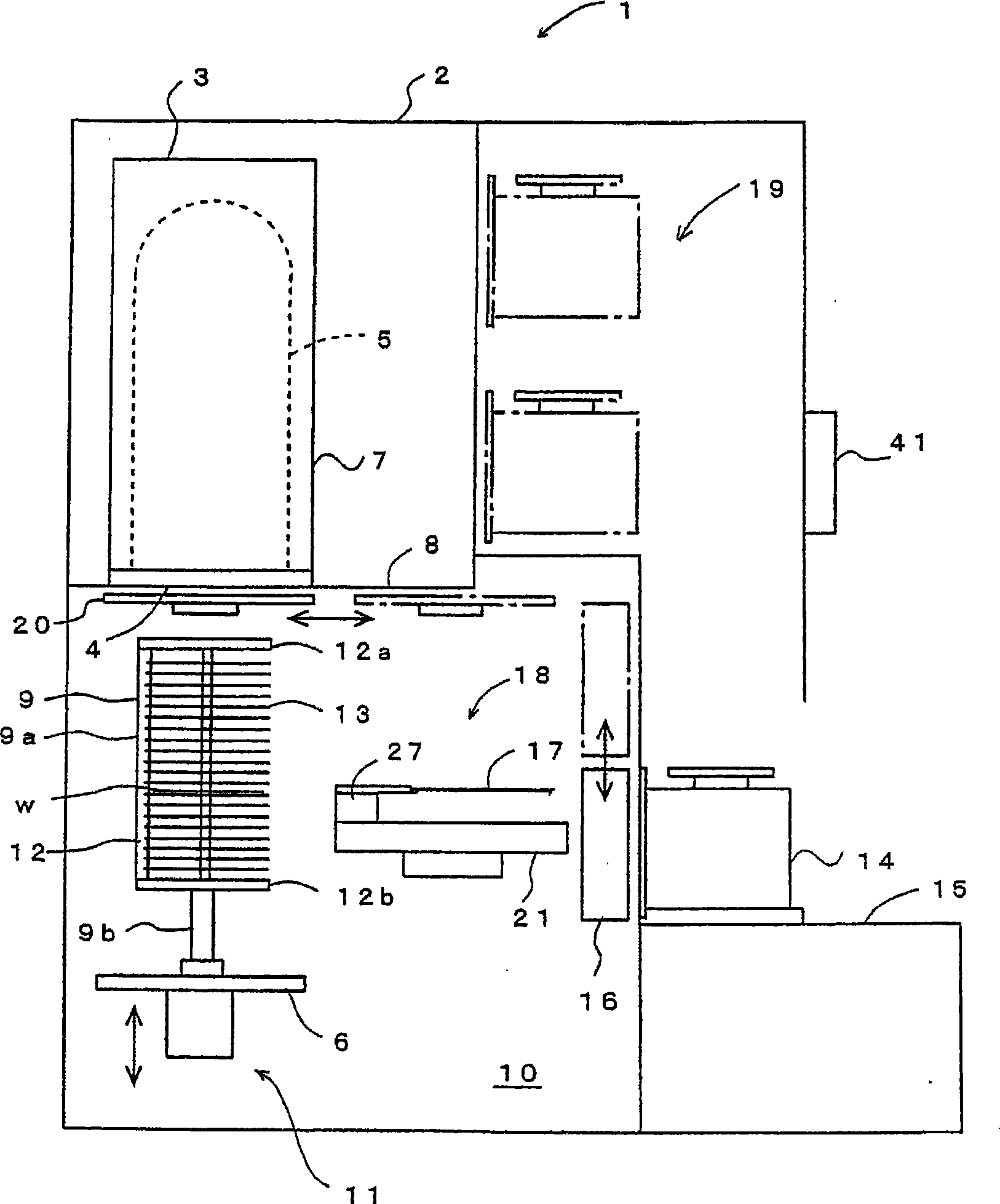

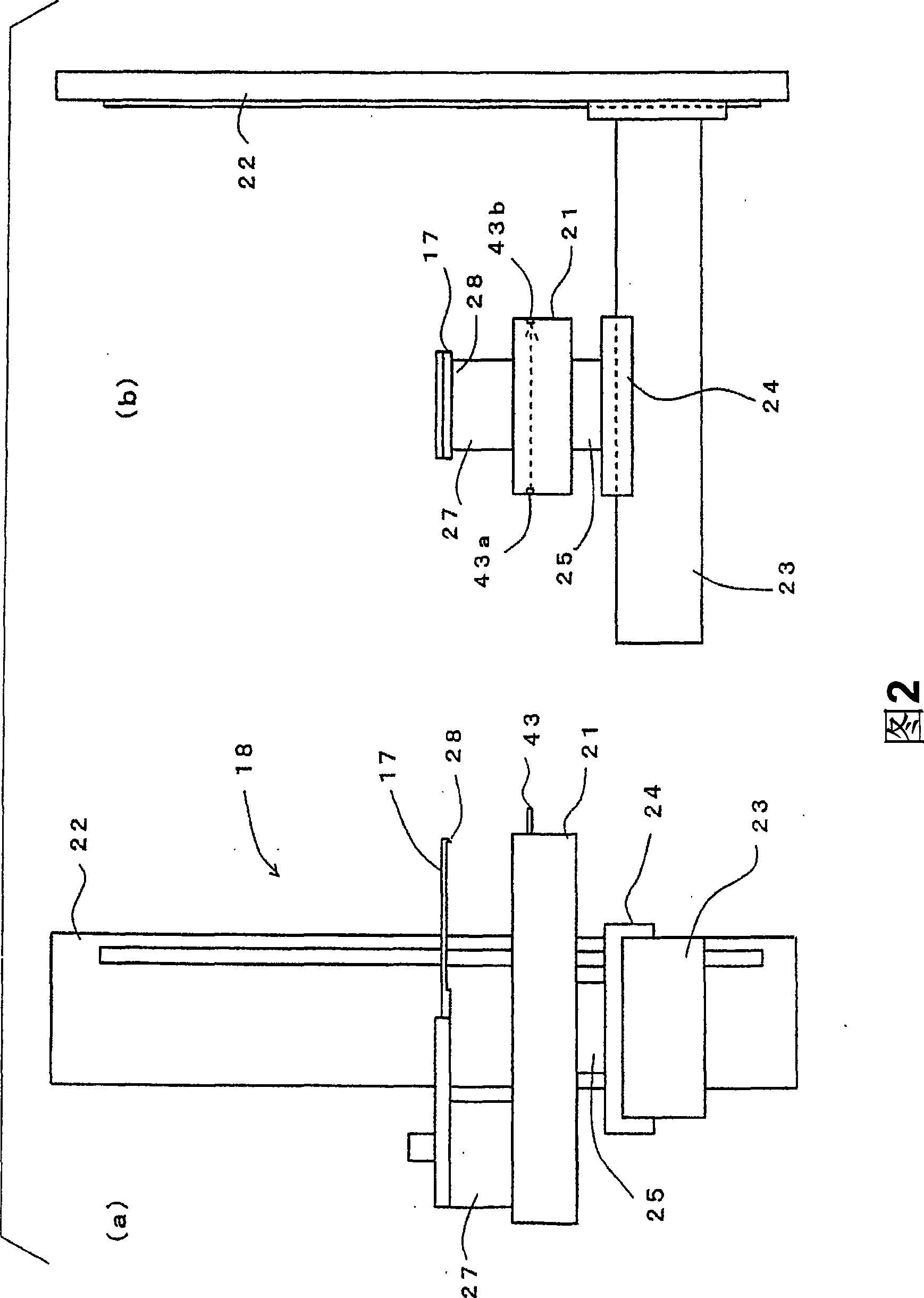

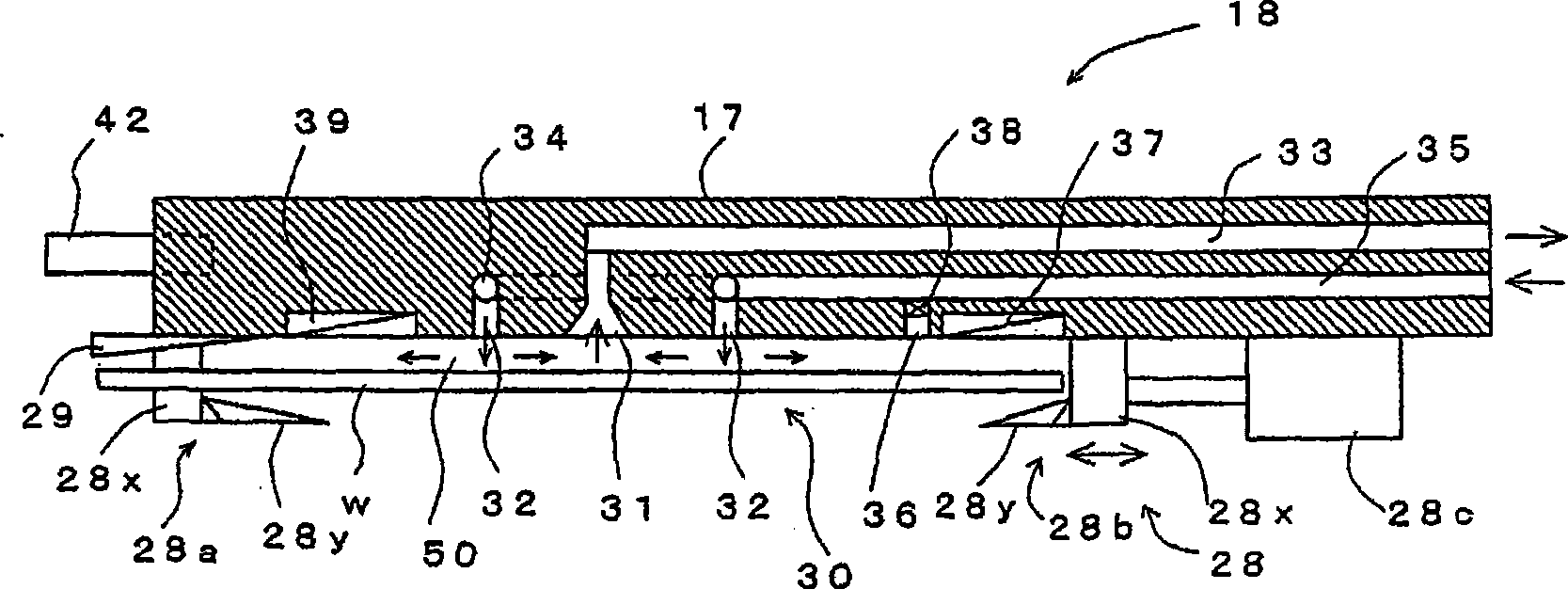

[0039] The best mode for carrying out the present invention will be described in detail below based on the drawings. figure 1 2( a ) is a front view schematically showing a substrate transfer device, and FIG. 2( b ) is a side view thereof. image 3 is a vertical cross-sectional view of the support portion, Figure 4 is the bottom view of the support.

[0040] In these figures, 1 is a vertical heat treatment apparatus (semiconductor manufacturing apparatus), and this vertical heat treatment apparatus 1 includes a frame body 2 forming an outer contour, and is arranged above the frame body 2 for accommodating a substrate such as a thin disk. A vertical heat treatment furnace 3 for performing a predetermined treatment such as CVD treatment on a semiconductor wafer w with a large diameter (300 mm in diameter or 400 to 450 mm in diameter). This heat treatment furnace 3 includes a vertically long treatment vessel such as a reaction tube 5 made of quartz whose lower part is opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com