Cargo deviation correction device for roller conveyor

A deviation correction device and conveyor technology, which is applied in the field of cargo positioning devices on the auxiliary conveyor conveying surface, can solve problems such as deflection and cargo position deviation, and achieve the effects of high reliability, improved production efficiency, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

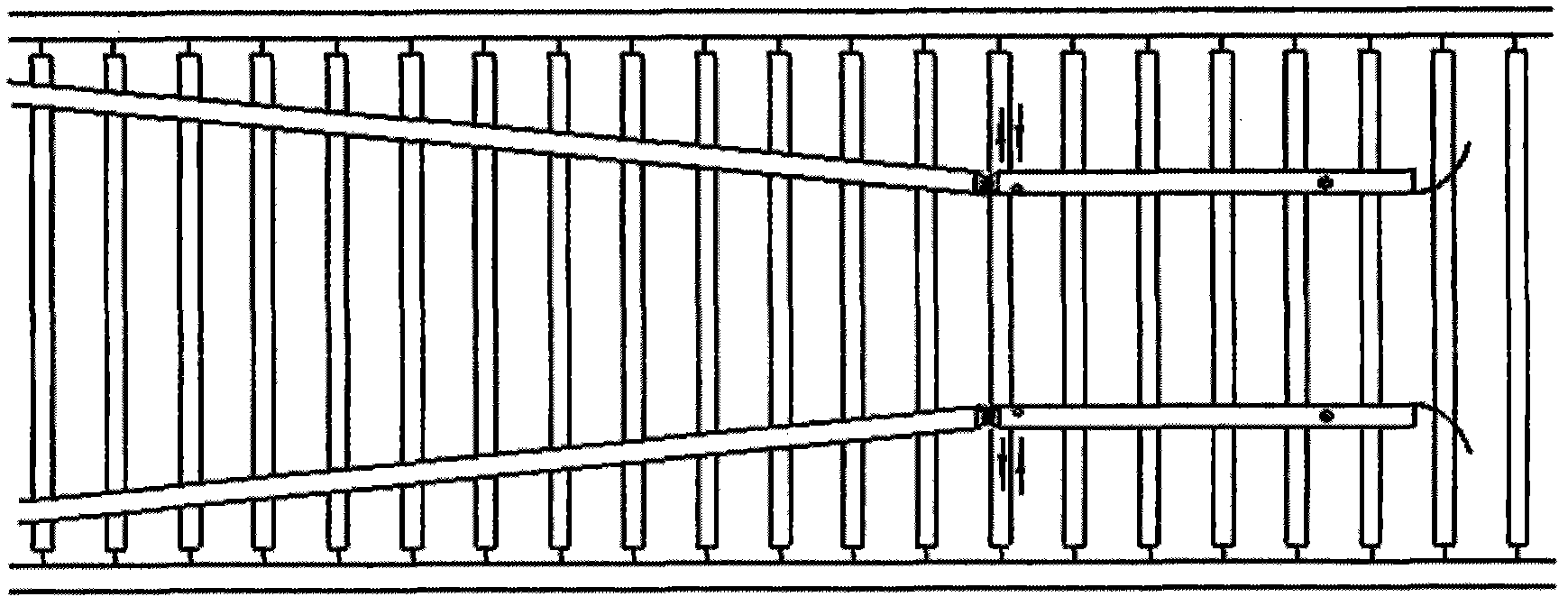

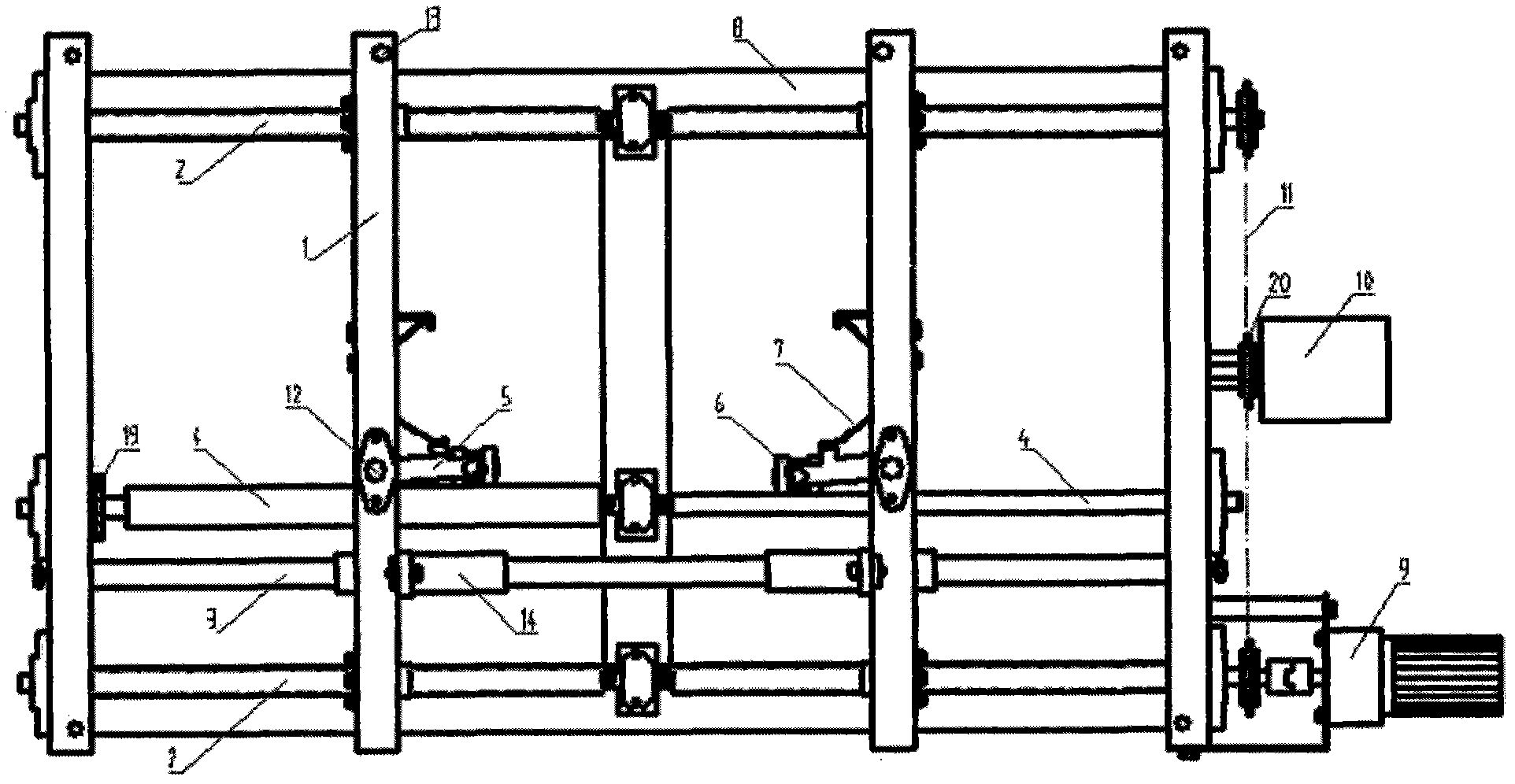

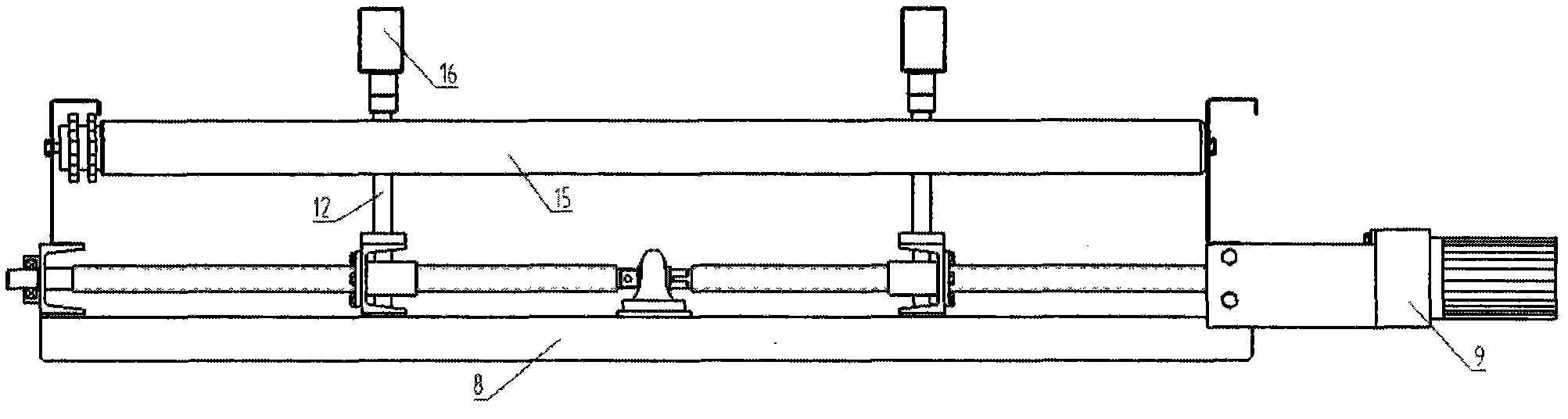

[0017] The goods deviation correcting device of the roller conveyor comprises a frame (8), and the frame is welded and formed by channel steel. Two groups of positive and negative thread screw rods (2) are fixed on the frame (8) with a bearing seat, and a sprocket wheel is arranged at one end thereof, and two groups of positive and negative screw screw rods (2) are connected together through a transmission chain (11). A tensioning wheel (20) is arranged on the transmission chain, and the tensioning wheel is fixed on the screw shaft of the frame control box (10), and the control box (10) is connected with the frame. The motor (9) is fixed on the frame (8) and is connected with one group of positive and negative thread screw rods (2) through a coupling and a sprocket. The translation frame (1) is set on two sets of positive and negative thread screw rods and fixed with the screw nuts, the two are at right angles, wherein the translation frame (1) is channel steel, and the notche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com