A linear actuator comprising an overload clutch

A technology for overload clutches and actuators, which is applied to mechanical equipment, belts/chains/gears, transmissions, etc., can solve problems such as speed limitations of actuators, and achieve the effect of facilitating installation work and improving self-breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

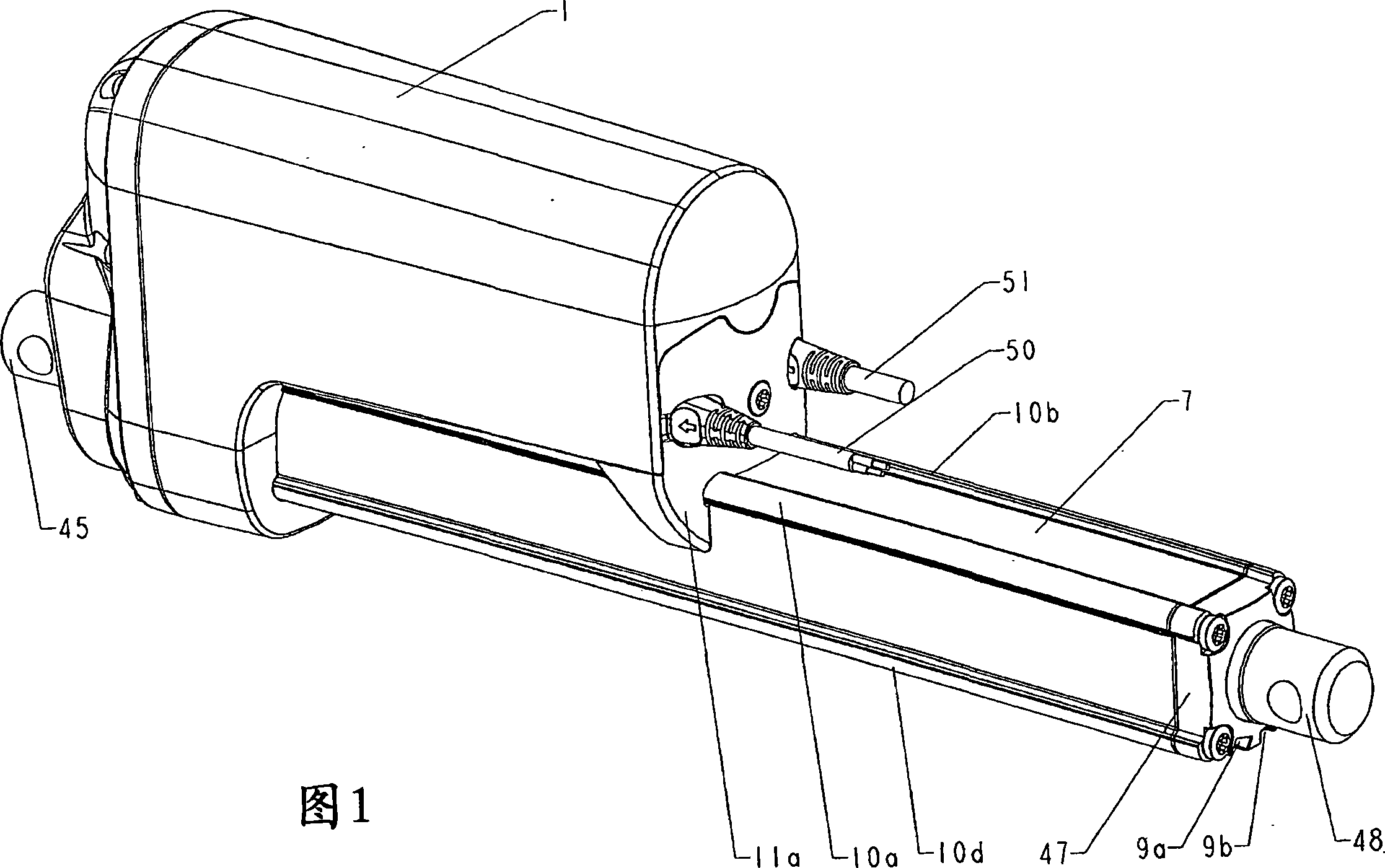

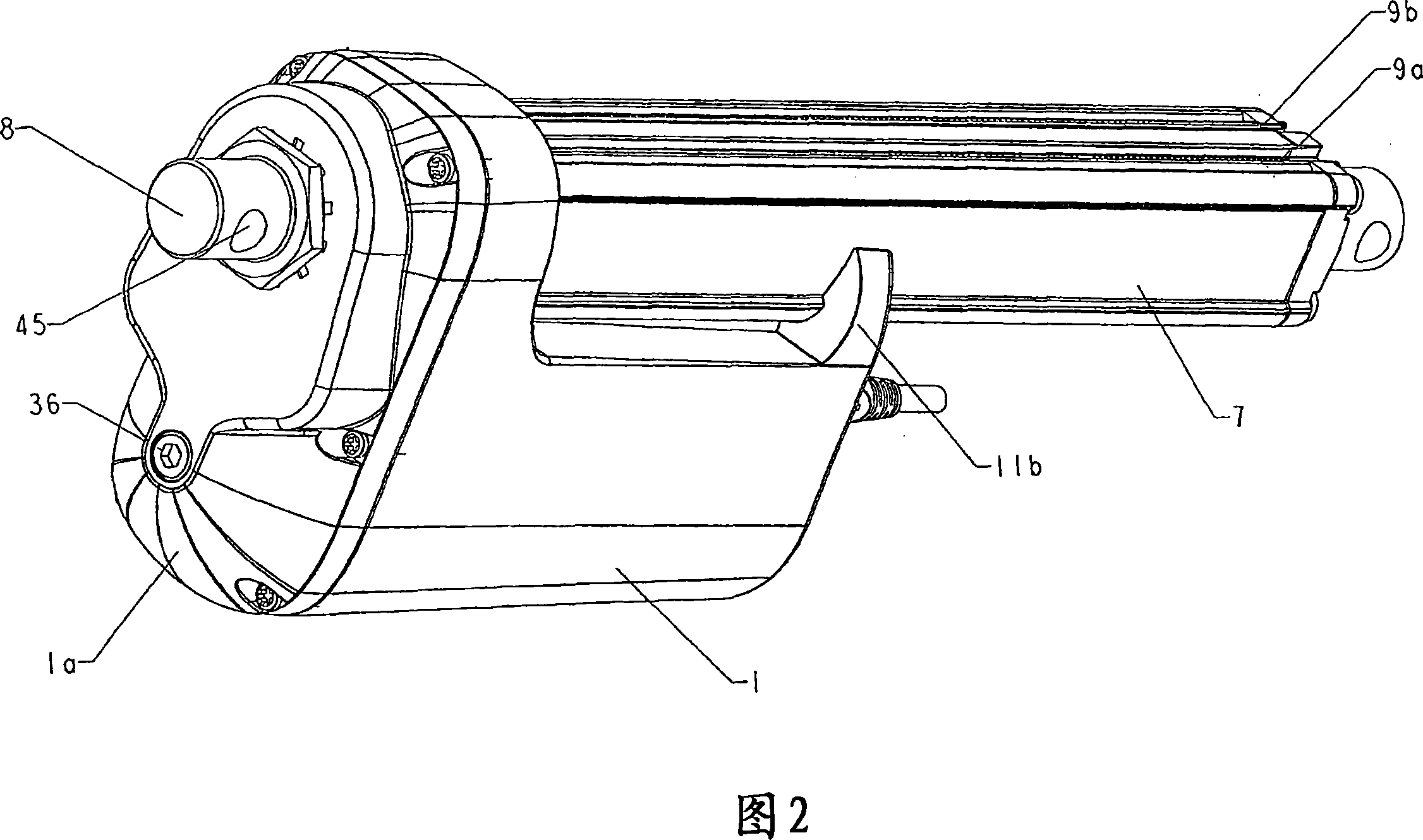

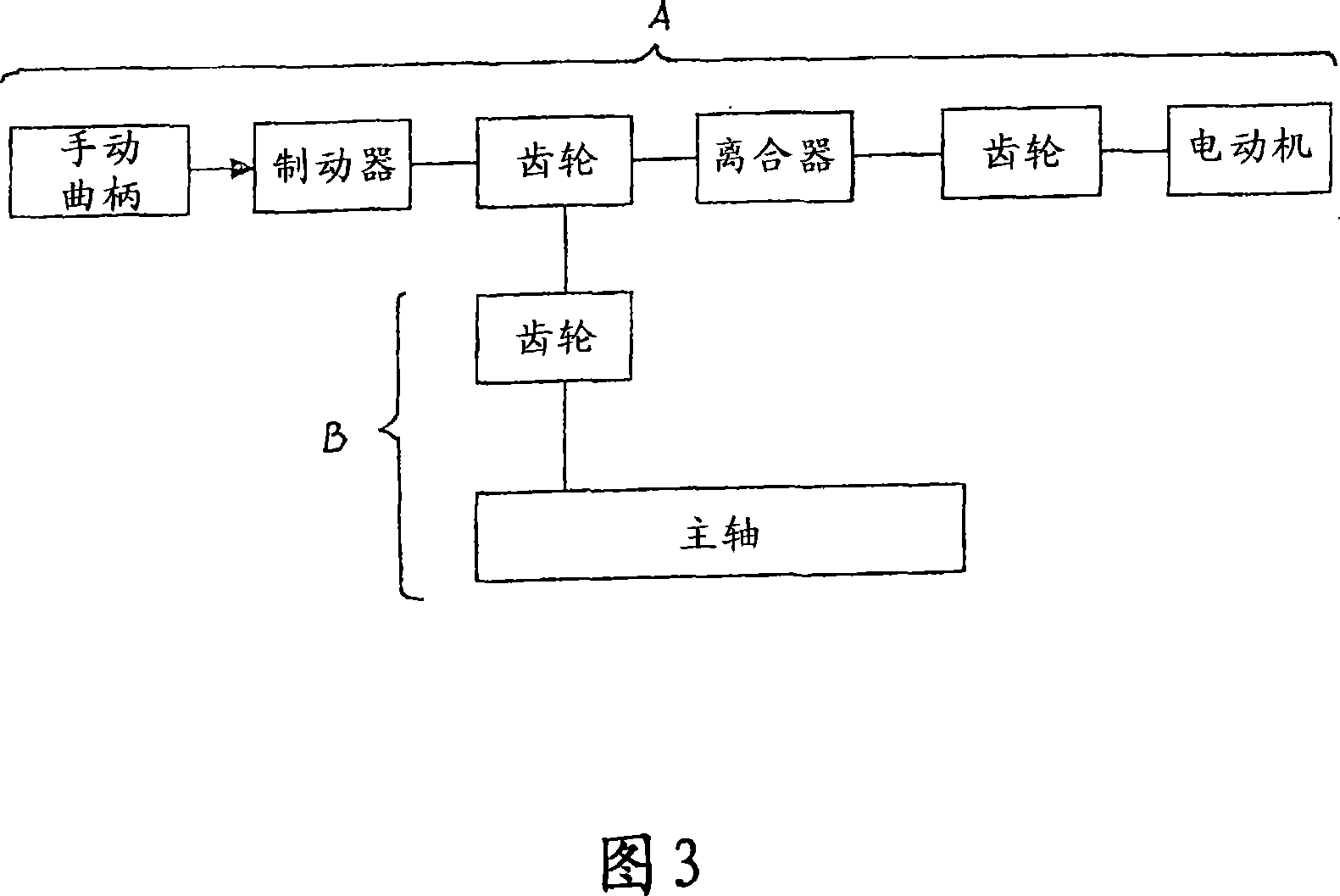

[0035] As shown in the accompanying drawing (Fig. 4), the main components of the actuator consist of a housing 1, a reversible motor 2, a multi-stage reduction gear 3, a main shaft 4, a main shaft nut 5, in the form of a tubular piston, also called an inner The actuating element 6 of the tube, the guide 7 , also called outer tube for this purpose, and finally the rear fastening 8 are formed.

[0036] The housing 1, made of molded aluminum for increased strength, has screw-fitted end shields 1a, and the joints are watertight (Figs. 1 and 2). The outer tube 7 is an extruded aluminum tube with a substantially square cross-section, assembled with screws, and its joints are also watertight. On one side thereof, the outer tube 7 is provided with two longitudinal grooves 9a, 9b, which can be used to mount additional equipment. In addition, the tube 7 is extruded with the helical channel of each corner, forming on the outside a longitudinally protruding strip 10a-d, the cross section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com