LCD device

A liquid crystal display, liquid crystal panel technology, applied in static indicators, instruments, instrument parts and other directions, can solve the problems of increased module cost, increased cost of circuit boards, low prices of metal shrapnel and metal conductive cloth, etc., and achieves good grounding. effect, stable clamping, improve the effect of electromagnetic wave interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

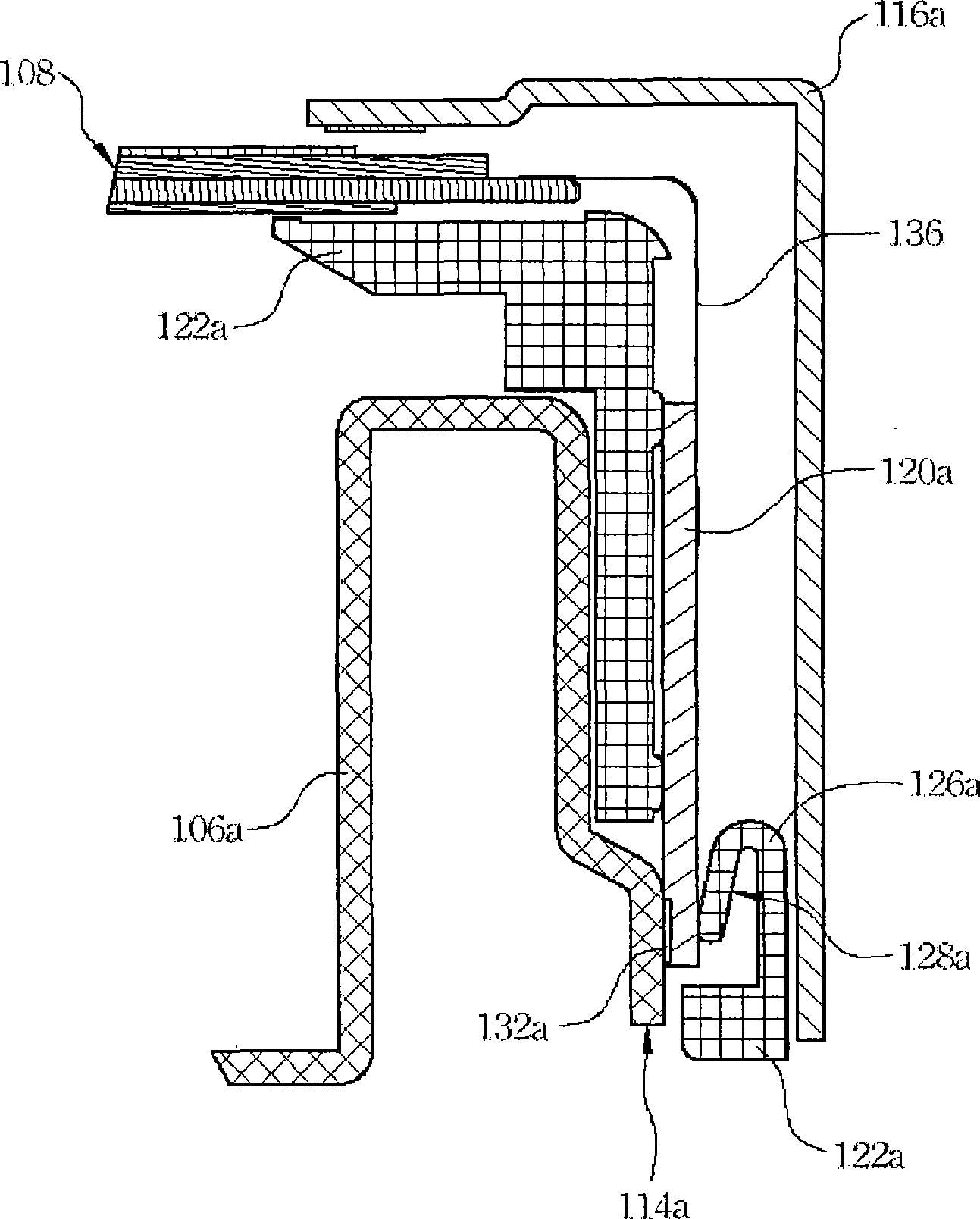

[0054] The invention discloses a liquid crystal display, which can make a printed circuit board obtain a good grounding effect without using additional parts, and effectively improve the problem of electromagnetic wave interference. In order to make the description of the present invention more detailed and complete, refer to the following description and cooperate with Fig. 1 to Figure 7B icon of the .

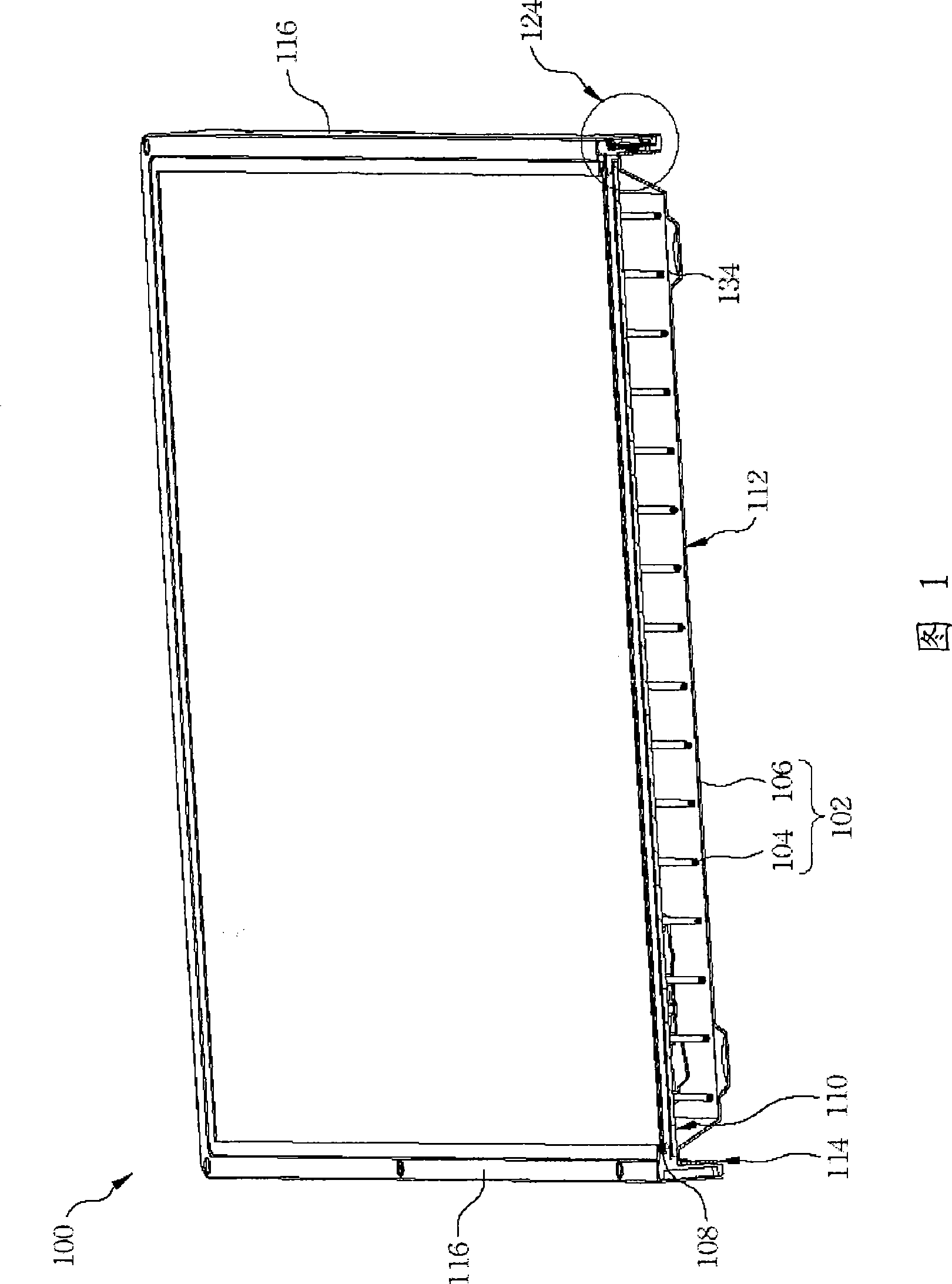

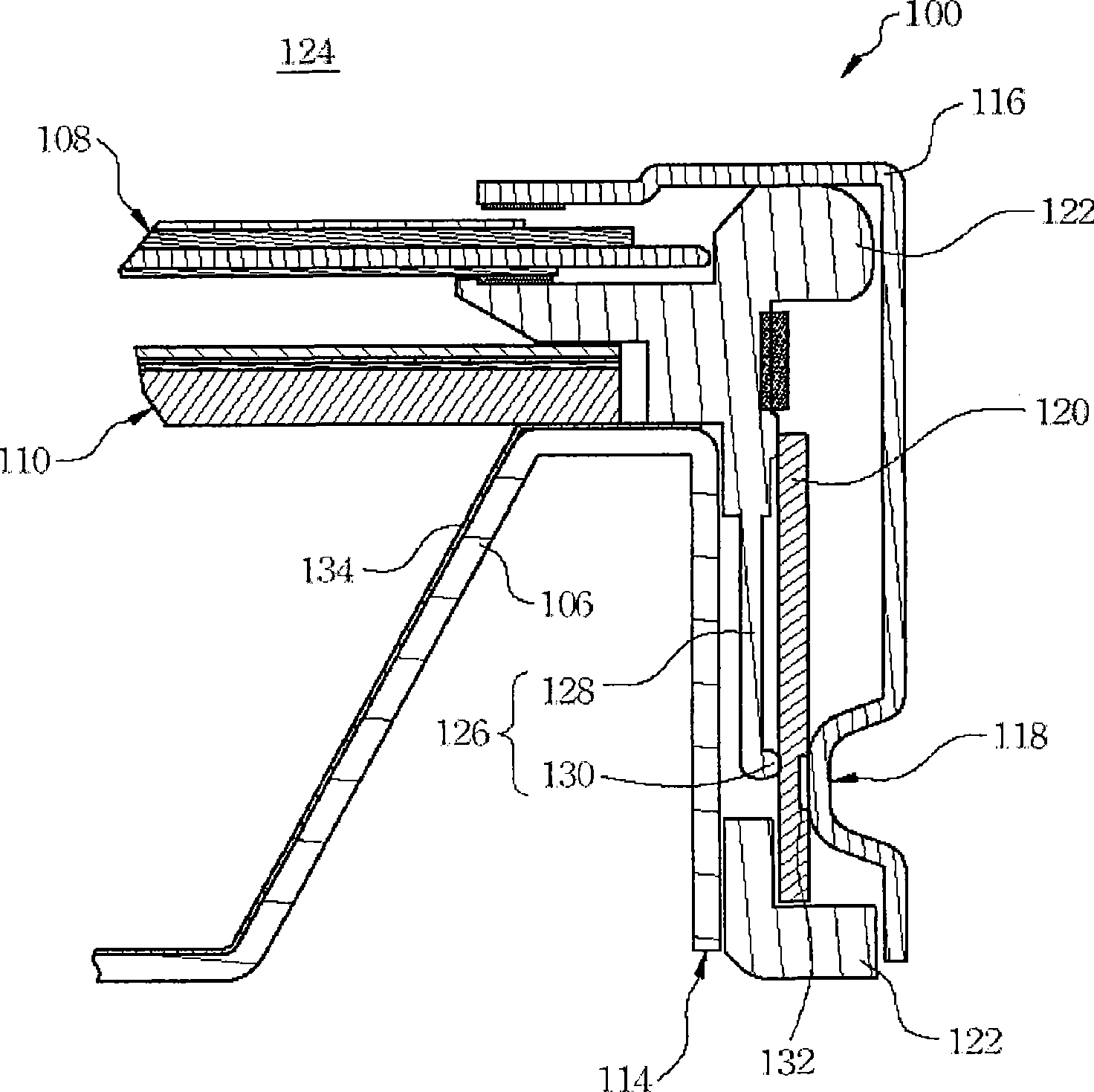

[0055] Please refer to Figure 1 with figure 2 , wherein FIG. 1 is a three-dimensional cross-sectional view illustrating a liquid crystal display according to a preferred embodiment of the present invention, and figure 2 Then it is an enlarged cross-sectional view showing the peripheral portion of the liquid crystal display shown in FIG. 1 . The liquid crystal display 100 mainly includes a backlight module 102 , a liquid crystal panel module 108 , a front frame 116 and a printed circuit board 120 . The backlight module 102 mainly includes a backplane 106 , a light source g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com