Plate corner connecting piece

A corner connector and plate technology, applied in the field of plate processing, can solve problems such as use limitations, plate damage, and rapid adjustment of plate angles that cannot be shaped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

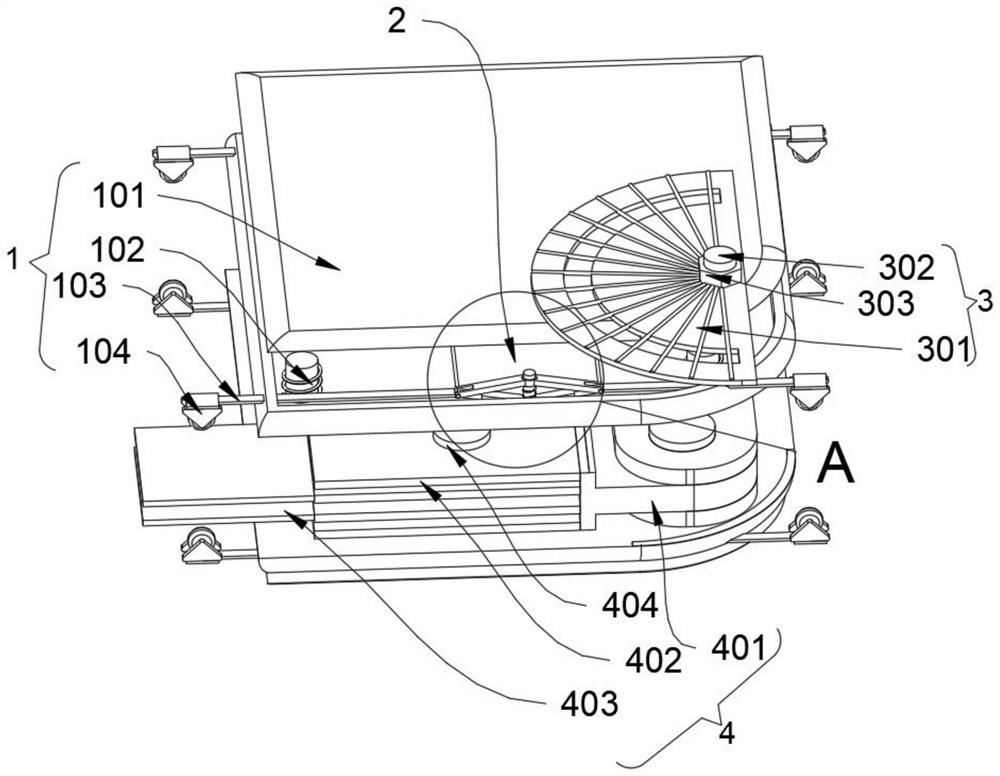

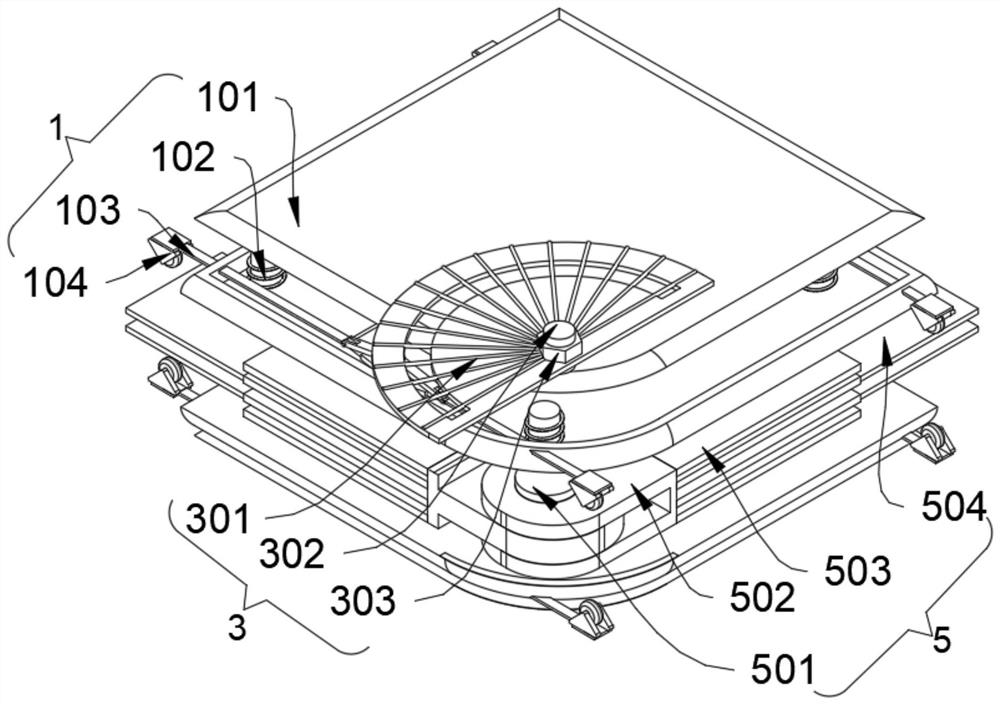

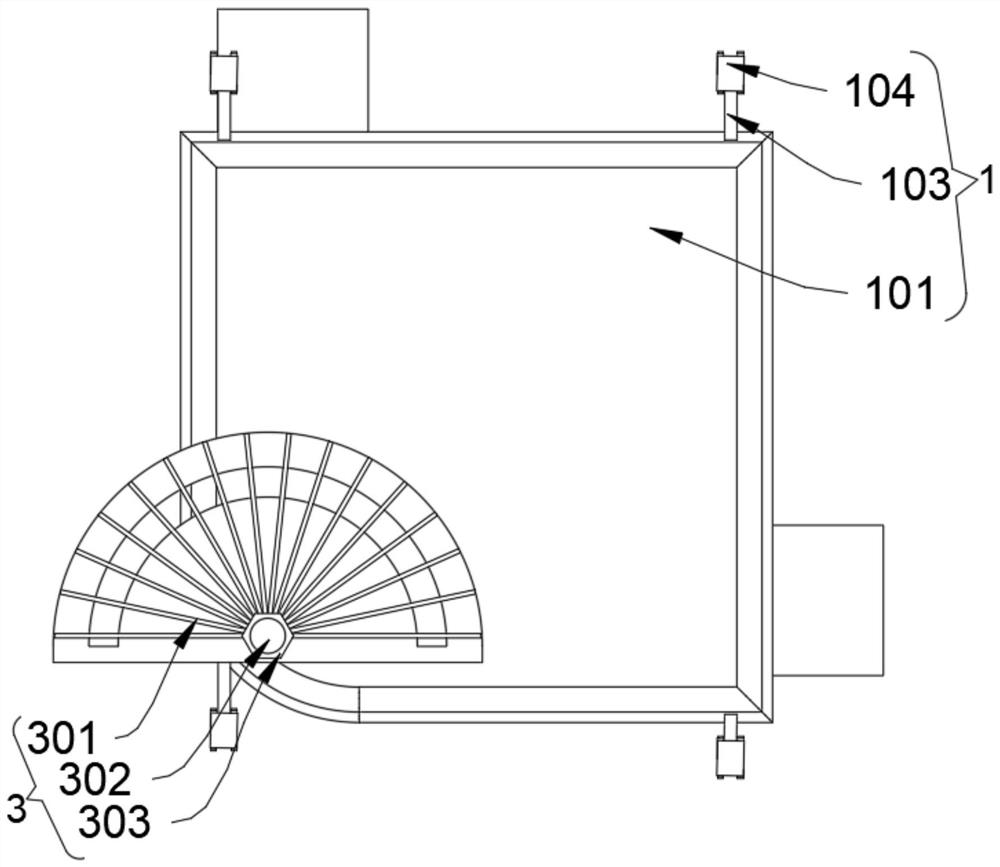

[0031] as attached figure 1 To attach Figure 8 Shown:

[0032] The invention provides a panel corner connector, which includes: a protective mechanism 2, an angle maintaining mechanism 3 and a connecting mechanism A4. There are four protective mechanisms 2 in total, and every two protective mechanisms 2 form a group, and two sets of protective mechanisms 2 respectively installed on the upper and lower sides of the outer protection mechanism 1; the angle holding mechanism 3 is screwed to the top left corner of the outer protection mechanism 1; the connecting mechanism A4 and the connecting mechanism B5 are hinged, and the connecting mechanism A4 and the connecting mechanism B5 are located at The inner position of the outer protection mechanism 1; the connecting mechanism A4 also includes a sub-board A403 and a clamping rod 404. There are two sub-boards A403, and the two sub-boards A403 are respectively plugged into the inner sides of the two main boards A402 to be slidably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com