Waste heat recovery heat exchanger for drilling platform

A waste heat recovery and drilling platform technology, which is applied in heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of exhaust waste heat and cooling water waste heat resources, etc., to reduce carbon deposition, not easy to leak, The effect of high heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

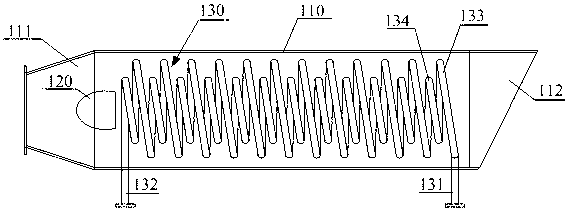

[0019] The following will combine Figure 1 ~ Figure 2 The waste heat recovery heat exchanger for the drilling platform of the present invention will be further described in detail.

[0020] see figure 1 , the waste heat recovery heat exchanger for the drilling platform according to the embodiment of the present invention includes a shell 110, a deflector 120 and a double-helix suspension coil 130;

[0021] The shell 110 is a cavity, one end of which is provided with a smoke inlet 111, and the other end is provided with a smoke outlet 112, and the smoke inlet 111 is connected with the exhaust port of the diesel engine for collecting the exhaust gas of the diesel engine smoke exhaust from the mouth;

[0022] The deflector 120 is arranged in the casing 110 and is close to the smoke inlet 111 of the casing 110;

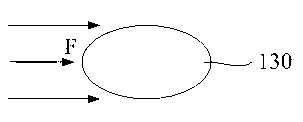

[0023] The double-helix suspension coil 130 is arranged in the shell 110, and the double-helix suspension coil 130 is used to transport the heated fluid medium;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com