Circulating colloid grinding and homogenizing machine

A homogenizer, circulating technology, used in cocoa, grain processing, food science, etc., can solve the problems of poor heat dissipation, insufficient heat dissipation, and large rotor wear, and achieve convenient equipment maintenance, fine grinding, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

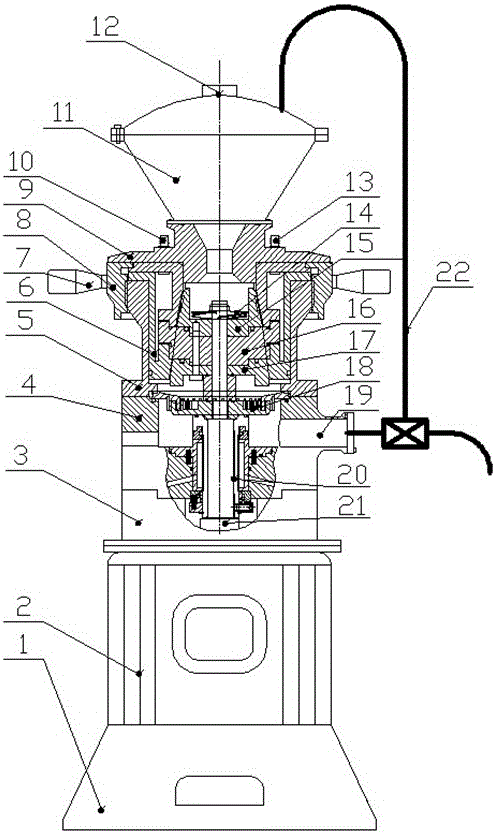

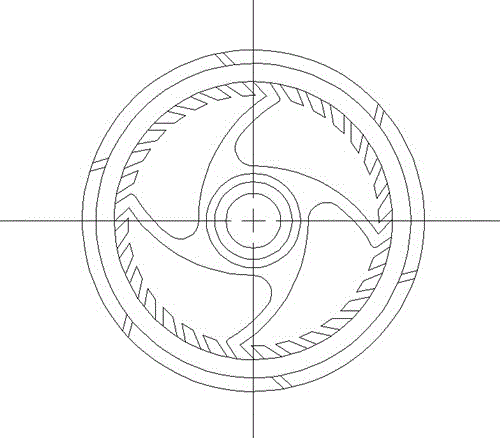

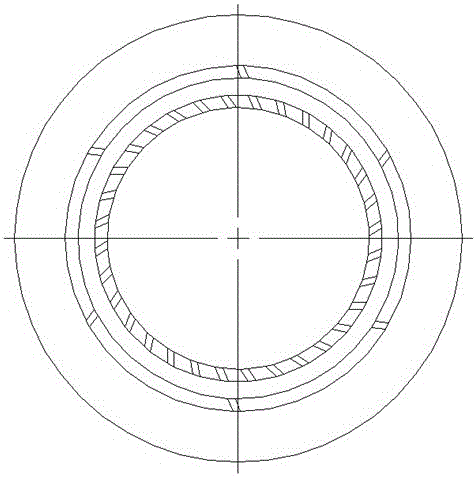

[0022] as attached figure 1 As shown, the circulating colloid grinding homogenizer includes a motor 2, a machine base 1, a body 3, a rotating blade 16, a three-stage grinding, a circulating body 23, a homogeneous disc, a mechanical seal water cooling joint, and a mechanical seal device 21; Organism 3 and motor 2 are installed on machine base 1, closed hopper 12 is set above body top cover 10, hopper 12 is a stainless steel product in the shape of a cone; 15. Composed of grinding body and homogeneous body, the grinding body is composed of three-level tooth protrusions and grooves from coarse to fine. The stator can be adjusted to the required distance from the rotor through the adjustment device. Through the adjustment of the adjustment device The fineness of the grinding body is gradually increased, and finally micro-nano-scale material particles are obtained; a mechanical seal group is set between the main shaft, the rotor and the body, and a discharge port is set at the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com