Totally-enclosed type multifunctional high-speed incinerating device and production process thereof

A fully enclosed, incineration device technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as affecting the normal flow of flue gas, emission of toxic and harmful gases, corrosion of pipe walls or mechanical parts, etc. Energy saving and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

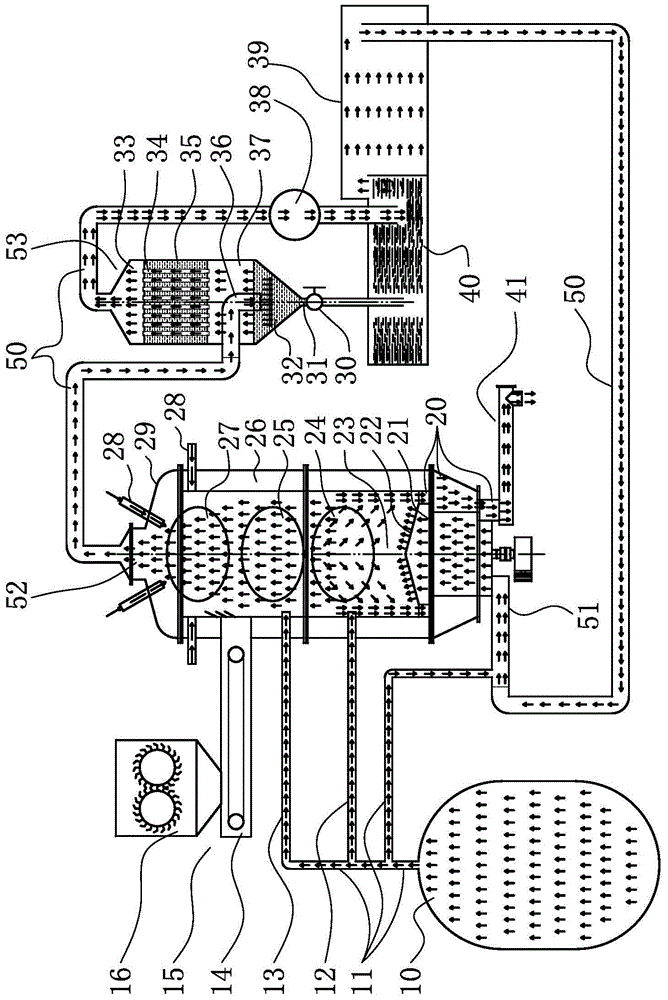

[0022] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — image 3 :

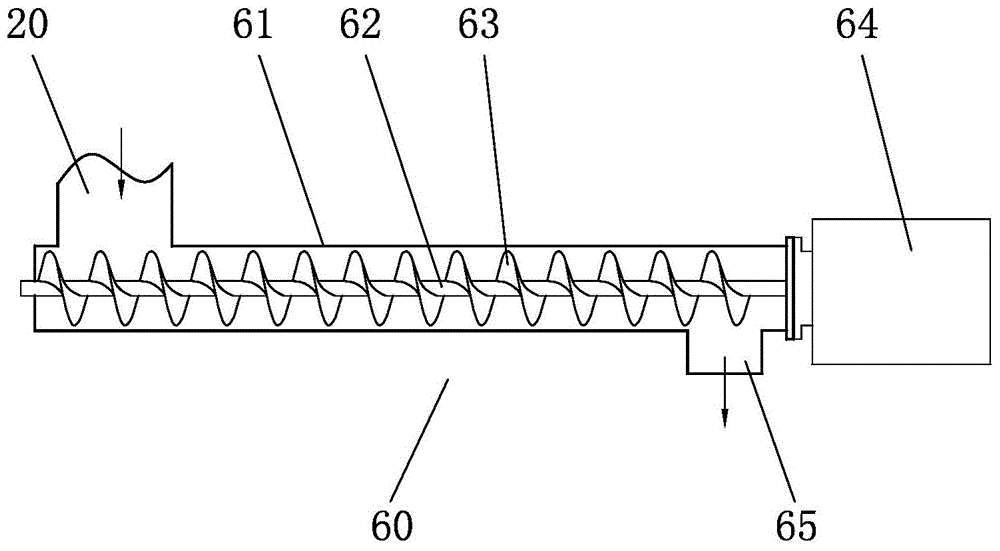

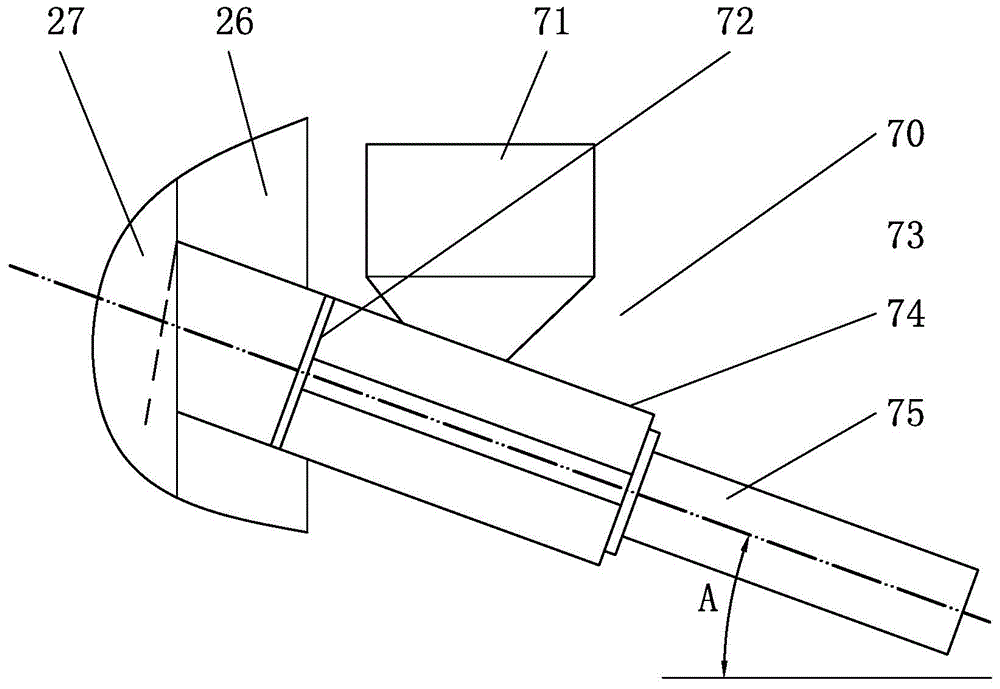

[0023] A fully enclosed multifunctional high-speed incineration device, including an incinerator 25, a feed mechanism 15 on the side wall of the incinerator 25, an ash lowering pipe 20 at the bottom of the incinerator 25, and an air inlet pipe 51, and the inner cavity of the furnace is formed sequentially from bottom to top There are residual ash cooling zone 23, primary combustion zone 24, secondary high-temperature combustion cracking zone 26 and cooling and decoking zone 27. The side wall of primary combustion zone 24 is provided with primary oxygen supply pipe 12 for primary combustion zone 24 supplementing oxygen. The side wall of the secondary high temperature combustion cracking zone 26 is provided with a secondary oxygen supply pipe 13 and the described feeding mechanism 15 for supplementing oxygen for the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com