Grinding device

A grinding device and grinding body technology, which is applied in the fields of medicine, chemical industry, beverage emulsion, and biology. It can solve the problems of equipment grinding that cannot meet user needs, poor heat dissipation conditions, chemical solutions, and large powder particles, etc., and achieves convenient maintenance. , Uniform particle size and more output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

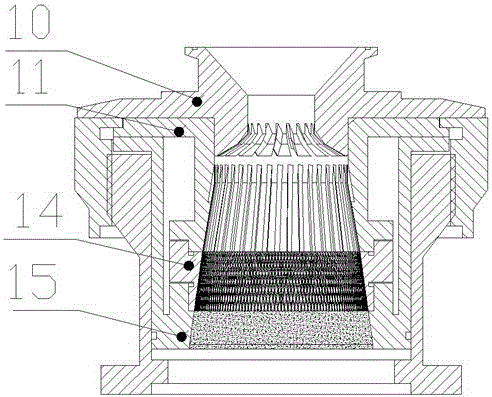

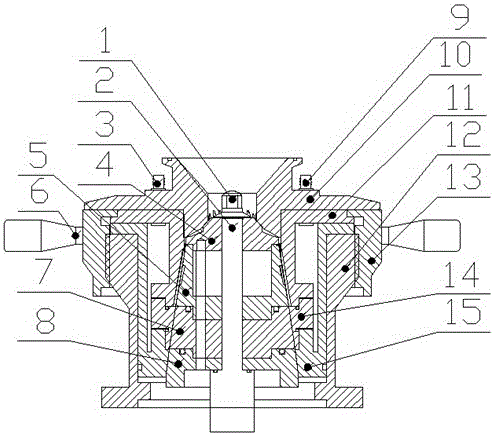

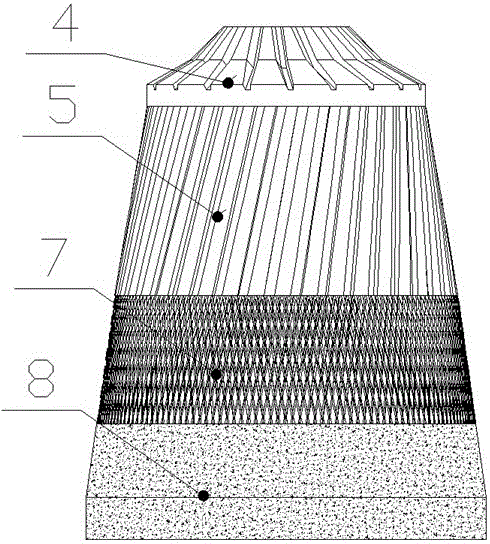

[0018] as attached figure 1 As shown, the grinding body consists of a main shaft 2, a third-stage static grinding body, a top cover 10, a fourth-stage dynamic grinding body, a casing 12, an adjusting disc 13, a handle 6, a lock nut 1, and inlet and outlet joints of coolant pipes; The device shell is fixed on the body. The upper end of the shell 12 has threads and the adjustment disc 13 to adjust the top cover 10 and the static grinding body; the dynamic grinding body is from thick to fine. The four-level tooth protrusions and grooves are used, and the fourth level is made of metal. The distance between the coating, the third-stage static grinding body and the top cover and the fourth-stage dynamic grinding body can be adjusted, and the fineness of the high-speed rotating grinding head is gradually increased to obtain micro-nano-scale material particles; the fourth-stage dynamic grinding body is fixed on the The main shaft 2 is locked by a lock nut at the front end of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com