Ground temperature regulation and snow melting device using natural geothermal heat and its application

A ground and geothermal technology, applied in the field of geothermal utilization systems, can solve problems such as increasing emissions and wasting energy, achieving the effects of less heat loss, preventing freezing or melting frost and snow, and preventing frost and snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

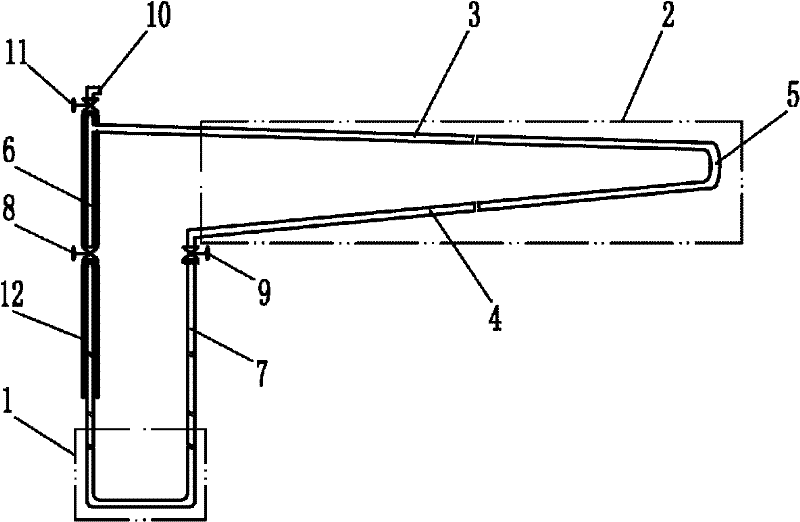

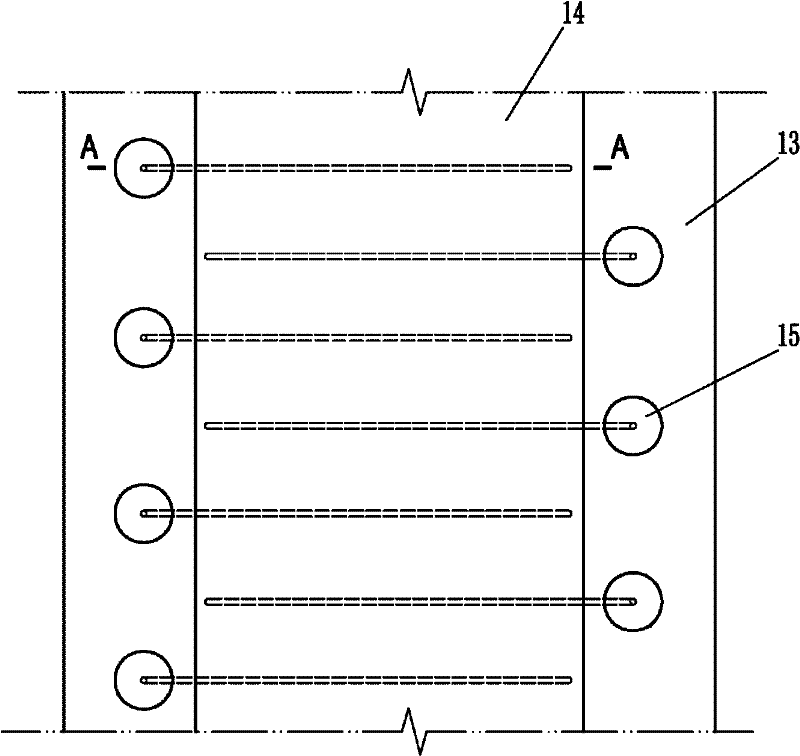

[0035] like figure 1 The shown ground temperature-regulating snow-melting device utilizing natural geothermal heat in the present invention includes a heat-collecting part 1, which is a U-shaped pipe, and is connected to the heat-dissipating part 2 through an output pipe 6 and a return pipe 7 to form a closed circuit. The circuit is equipped with a low-boiling-point working medium—liquid ammonia (not specifically shown in the figure) as a heat-transfer working medium, which fills most of the space inside the heat collector. The heat dissipation part 2 is composed of a heat dissipation pipe 3 and a collector pipe 4. The heat dissipation pipe 3 is higher than the collector pipe 4 and communicates with the collector pipe through the return part 5. In the heat dissipation part 2, the heat dissipation pipe 3 and the output pipe 6 The connected inlet is higher than the outlet of the header 4 connected to the return pipe 7 . In order to realize the smooth circulation of the heat tra...

Embodiment 2

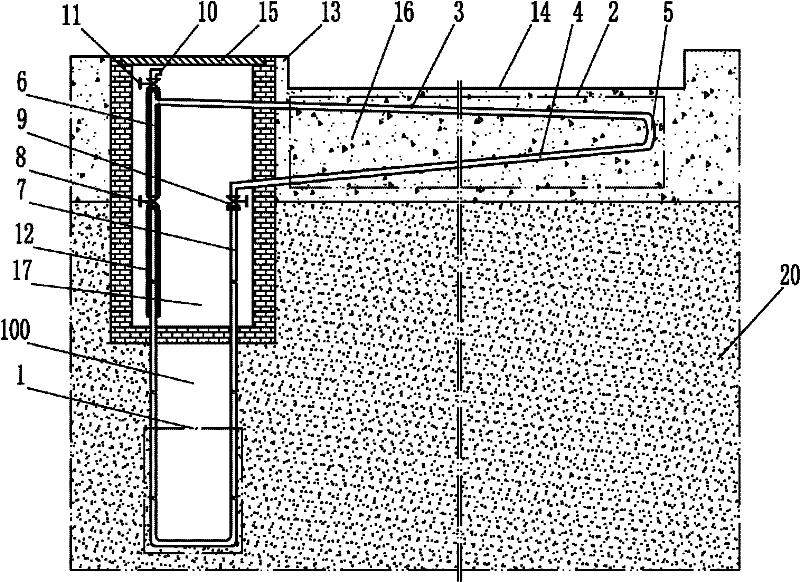

[0043] like Figure 4 The ground temperature-regulating snow-melting device using natural geothermal heat shown differs from Embodiment 1 in that an insulating layer 12 is also provided on the surface of the return pipe 7 in order to prevent the condensed low-boiling point working fluid from condensing in the return pipe 7 from dissipating heat to the shallow rock and soil. In addition, in order to be able to discharge the gaseous impurities mixed into the circuit with the low boiling point working fluid at any time, an exhaust port 18 and an exhaust switch valve 19 are provided at the end of the heat pipe. In this example, the inclinations of the radiating pipe and the collecting pipe are 1:100 and 2:100 respectively, and the overall height of the radiating part is lower.

[0044] like Figure 5 and Image 6The difference between the road structure shown in the above-mentioned ground temperature-regulating snow-melting device using natural geothermal heat and the first embo...

Embodiment 3

[0050] like Figure 7 The present invention utilizes natural ground heat to adjust the temperature and snow-melting device on the ground. The difference from Embodiment 1 is that the heat collecting part 1 is a blind pipe, and a low-boiling-point working medium 25 is arranged in the dead pipe, and the opening of the output pipe 6 is located at the top of the dead pipe. The lower end of the return pipe 7 is located at the bottom of the dead leg. In order to improve the heat dissipation efficiency, the heat dissipation part includes a plurality of heat dissipation pipes 3 arranged in parallel. In order to avoid unexpected loss of heat and unexpected heat exchange between the output pipe and the return pipe, an insulating layer 12 is provided outside the output pipe 6 and the return pipe 7 . In addition, in order to facilitate the addition of low-boiling-point working fluid into the circuit, a low-boiling-point working fluid filling port 10 and a corresponding filling switch val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com