Carbon nano-tube enhanced cement-base composite material and preparation method thereof

A carbon nanotube and cement-enhancing technology, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc. The effect of increasing the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

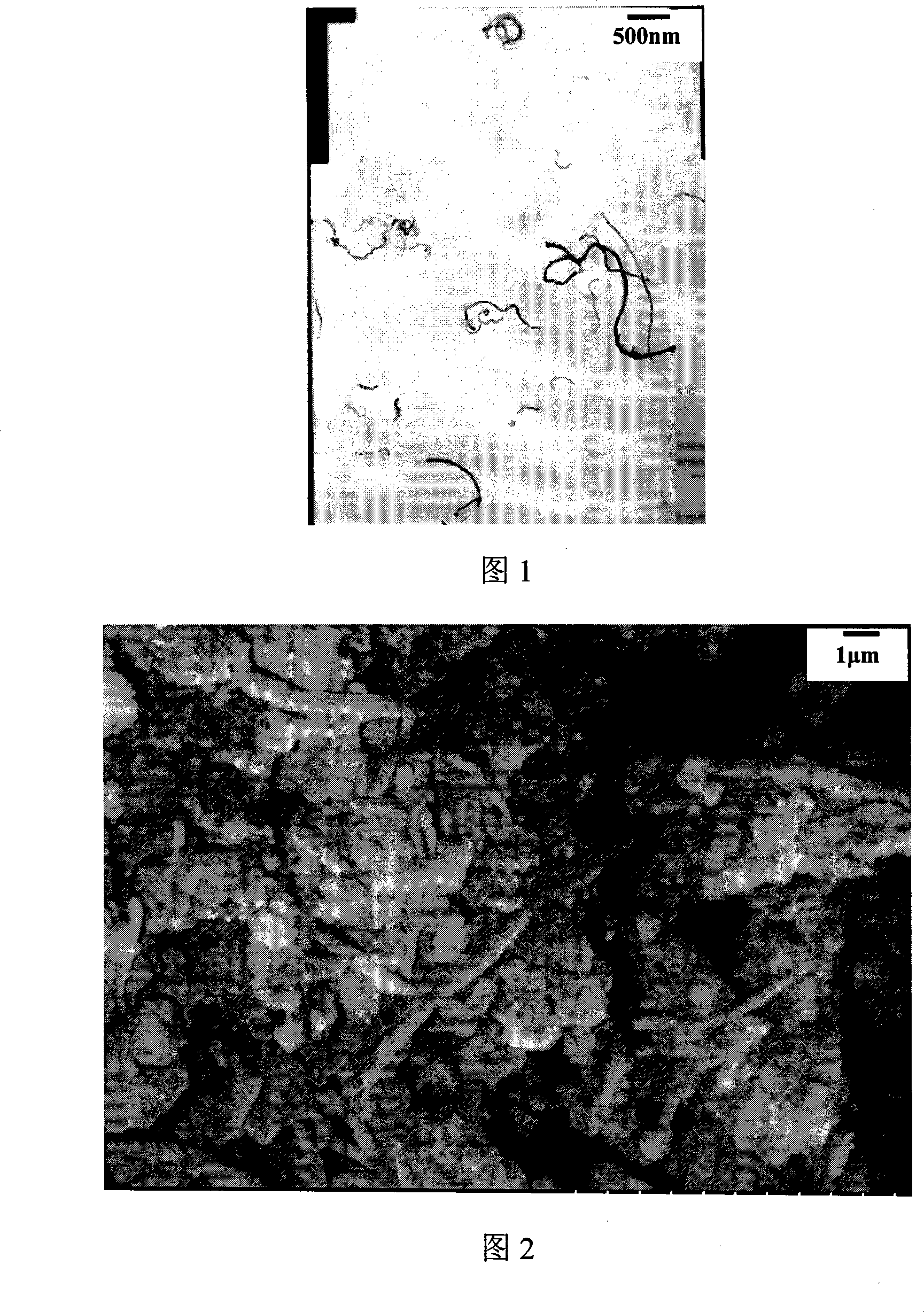

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: The carbon nanotube reinforced cement-based composite material of this embodiment is made of dispersant, carbon nanotube, thickening stabilizer, cement admixture, superplasticizer, defoamer and cement, wherein The mass ratio of carbon nanotubes to dispersant is 1:0.1~10, the mass ratio of carbon nanotubes to cement admixture is 1:2~200, and the mass ratio of carbon nanotubes to superplasticizer is 1:0.1~ 20. The mass ratio of carbon nanotubes to thickening stabilizer is 1:0.1~20, the mass ratio of carbon nanotubes to defoamer is 1:0.05~5, and the mass ratio of carbon nanotubes to cement is 1:20~ 2000.

[0017] The thickening stabilizer described in this embodiment is cellulose, polyethylene glycol octyl phenyl ether (Triton X-100), nonylphenol polyoxyethylene (OP) emulsifier, Arabic gum (AG), poly One or more combinations of vinyl alcohol and polyvinylpyrrolidone; wherein the cellulose is methyl cellulose, carboxymethyl cellulose or carboxyethyl cellulose...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that carbon fibers are added to the raw materials of carbon nanotube-reinforced cement-based composite materials, and the mass ratio of carbon nanotubes to carbon fibers is 1:0.5-10. Others are the same as in the first embodiment.

[0019] The carbon fibers in this embodiment are chopped polyacrylonitrile (PAN) carbon fibers with a nominal diameter of 7 μm and a length of 1-6 mm.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the thickening stabilizer is cellulose and polyethylene glycol octylphenyl ether (Triton X-100) nonylphenol polyoxyethylene (OP) One or a combination of emulsifiers, gum arabic (AG), polyvinyl alcohol, and polyvinylpyrrolidone; wherein the cellulose accounts for 0.4-2.0% of the total mass of the thickening and stabilizing agent. Others are the same as in the second embodiment.

[0021] When polyethylene glycol octylphenyl ether (Triton X-100), nonylphenol polyoxyethylene (OP) emulsifier, gum arabic (AG), polyvinyl alcohol, and polyvinylpyrrolidone in this embodiment are combined , they can be mixed in any ratio. The cellulose is methyl cellulose, carboxymethyl cellulose or carboxyethyl cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com