High-concentration and high-purity graphene slurry and preparation method and application thereof

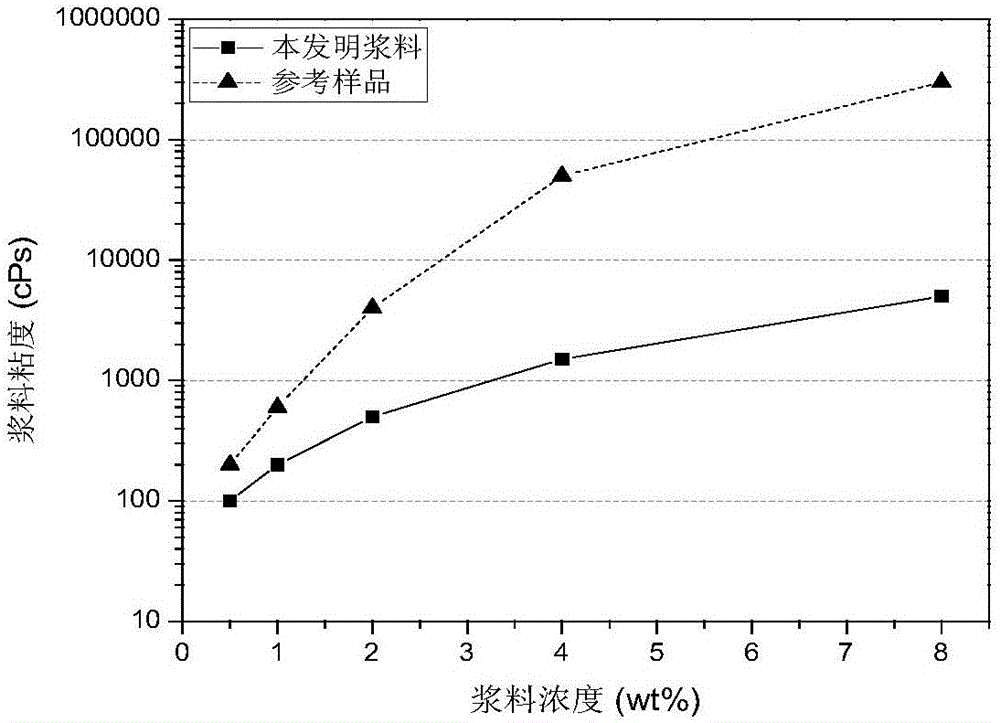

A graphene, high-purity technology, applied in the field of high-concentration, high-purity and highly pre-dispersed graphene slurry and its preparation, can solve the problems of low yield, high cost, and difficulty in maintaining a high degree of graphene pre-dispersion. , to achieve the effect of low viscosity and high concentration cleavage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

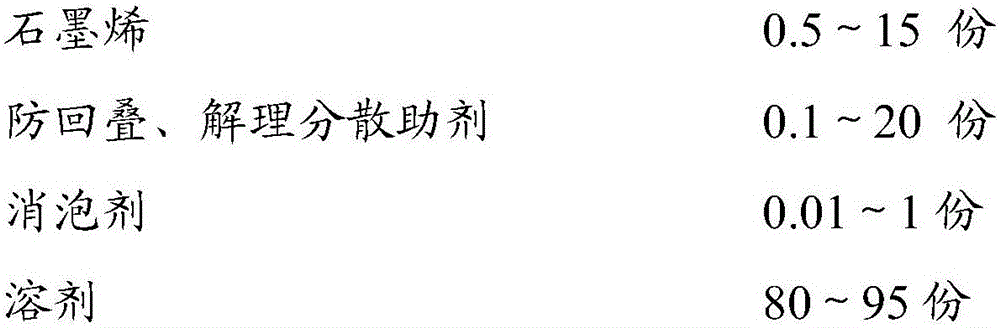

[0035] A high-concentration, high-purity, highly pre-dispersed graphene slurry and its preparation:

[0036] Add 10 parts of graphene, 2 parts of polyurethane, 2 parts of hydroxypropyl methylcellulose, 1 part of polyethylene oxide, 0.01 part of dimethylsiloxane, and 85 parts of N-methylpyrrolidone in the material tank in parts by mass ;

[0037] According to the above formula, graphene, polyurethane, hydroxypropyl methylcellulose, polyethylene oxide, dimethylsiloxane, and N-methylpyrrolidone are high-energy cleaved and dispersed uniformly to obtain the graphene slurry material;

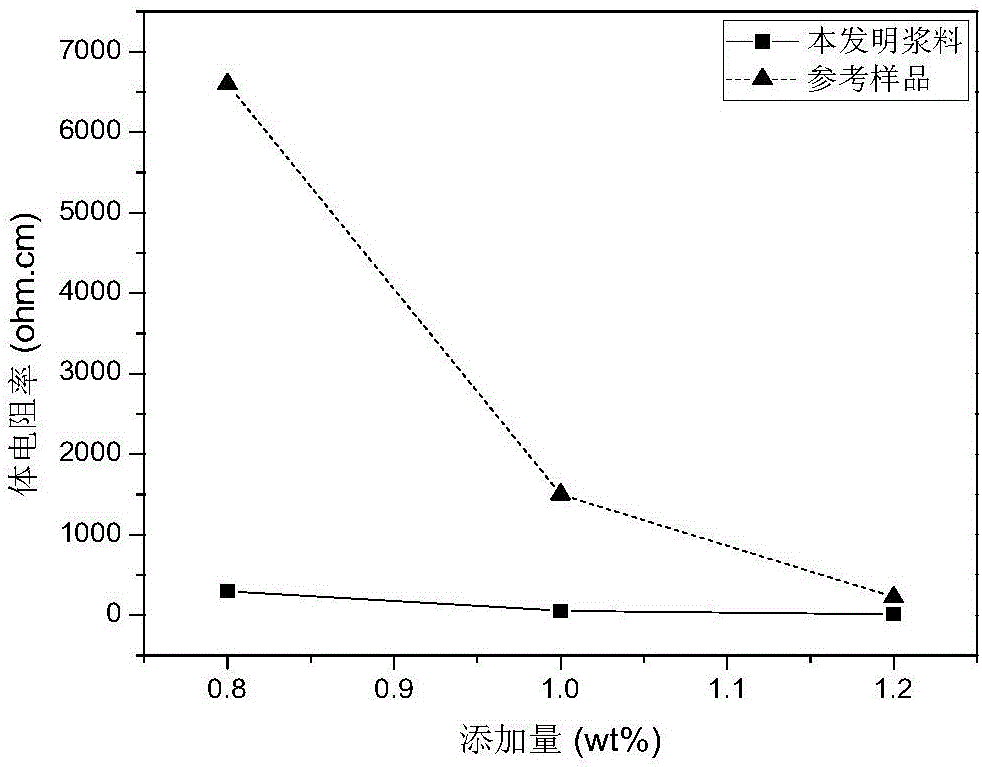

[0038] With conductive agent: polyvinylidene fluoride: the weight ratio of lithium iron phosphate=1:3:96 makes lithium ion battery positive electrode slurry, and the conductive agent in formula adopts graphene slurry of the present invention and untreated For graphene, add N-methylpyrrolidone to control the viscosity of the slurry and stir evenly. After 4 hours, the slurry is coated on a PET film an...

Embodiment 2

[0040] A high-concentration, high-purity, highly pre-dispersed graphene slurry and its preparation:

[0041] Add 12 parts of graphene, 0.2 parts of sodium carboxymethyl cellulose, 0.2 parts of xanthan gum, 0.2 parts of guar gum, 0.2 parts of carrageenan, 0.2 parts of GP type defoamer, and 87 parts of water in the material tank according to the number of parts by mass middle;

[0042] According to the above formula, graphene, sodium carboxymethyl cellulose, xanthan gum, guar gum, carrageenan, GP type defoamer, water, high-energy cleavage, and uniform dispersion can obtain the graphene slurry ;

[0043] With conductive agent: water-based epoxy resin: water-based epoxy curing agent: the weight ratio of calcium carbonate=1:33:33:33 prepares water-based epoxy coating, and the conductive agent in the formula adopts graphene slurry of the present invention respectively As well as untreated graphene, add an appropriate amount of water to control the viscosity, add a small amount of ...

Embodiment 3

[0045] A high-concentration, high-purity, highly pre-dispersed graphene slurry and its preparation:

[0046] Add 8 parts of graphene, 2 parts of nano conductive carbon black, 2 parts of polyamide wax, 0.5 part of hydroxypropyl methylcellulose, 1.5 parts of polyethylene glycol, 0.01 part of dimethylsiloxane, 44 parts by mass parts Parts of N-methylpyrrolidone, 44 parts of N-vinylpyrrolidone in material tank;

[0047] According to the above formula, graphene, polyamide wax, hydroxypropyl methylcellulose, polyethylene glycol, dimethyl siloxane, N-methylpyrrolidone, N-vinylpyrrolidone, high-energy cleavage, uniform dispersion , to obtain the graphene slurry;

[0048]With conductive agent: polyvinylidene fluoride: the weight ratio of lithium iron phosphate=2:3:95 makes lithium ion battery positive electrode slurry, and the conductive agent in formula adopts graphene slurry of the present invention and untreated For graphene, add N-methylpyrrolidone to control the viscosity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com