High-efficiency banana oil paint detergent

A technology of banana water and cleaning agent, applied in the field of cleaning agents, can solve the problems of poor effect, strong corrosiveness, slow cleaning speed, etc., and achieve the effect of improving paint stripping effect, paint stripping efficiency, and increasing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

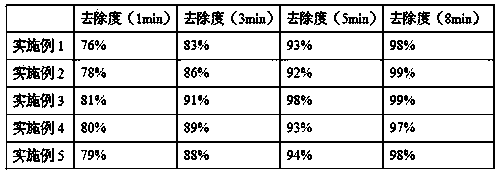

Examples

preparation example Construction

[0012] The preparation method of a high-efficiency banana water paint cleaning agent of the present invention comprises the following steps: first, deionized water is heated to 35-45 ℃; then banana water, sodium dodecylbenzene sulfonate, sodium hydroxide, ethoxylate Alkylated sodium alkyl sulfate and coconut oil fatty acid diethanolamide are added into deionized water for stirring. After stirring evenly, let it stand and cool down to 20-25° C., then add dichloromethane while stirring, and stir evenly.

[0013] The following examples are all prepared by this method.

Embodiment 1

[0015] A high-efficiency banana water paint cleaning agent, consisting of the following components in parts by weight: 20 parts of banana water, 8 parts of sodium dodecylbenzenesulfonate, 10 parts of sodium hydroxide, ethoxylated alkyl sulfuric acid 6 parts of sodium, 8 parts of coconut oil fatty acid diethanolamide, 10 parts of dichloromethane, 100 parts of deionized water.

Embodiment 2

[0017] A high-efficiency banana water paint cleaning agent, consisting of the following components by weight: 25 parts of banana water, 10 parts of sodium dodecylbenzenesulfonate, 15 parts of sodium hydroxide, ethoxylated alkyl sulfuric acid 8 parts of sodium, 10 parts of coconut oil fatty acid diethanolamide, 12 parts of dichloromethane, 100 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com