Corrosion preventive for being coated on surfaces of aluminium alloy plates and preparation method of corrosion preventive

An anti-corrosion, aluminum alloy technology, applied in anti-corrosion coatings, pretreatment surfaces, devices for coating liquids on surfaces, etc. performance, the effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] 1. Preparation of aluminum alloy preservative

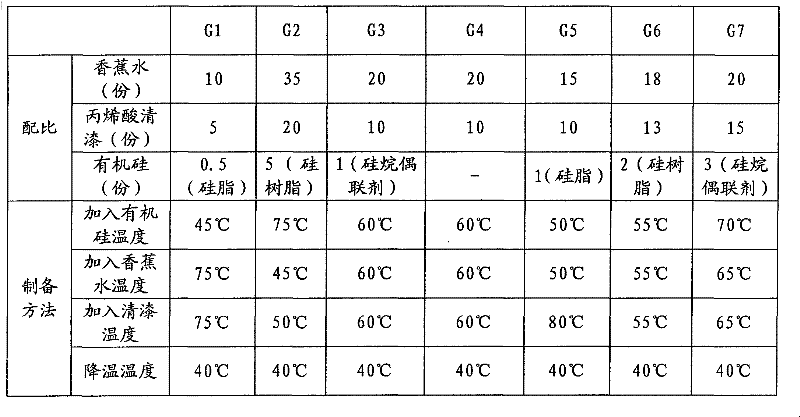

[0025] Examples 1-7 show the preservative formulations with the content of each component, prepared by the preparation method, see Table 1 for details.

[0026] Table 1 Preservative ratio and preparation method

[0027]

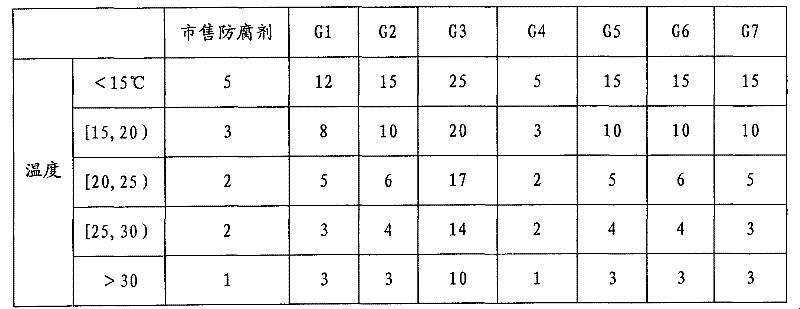

[0028] 2. Using the preservatives prepared in Examples 1 to 7 above and commercially available preservatives to carry out anticorrosion treatment on aluminum alloy plates, see Table 2 for details.

[0029] Table 2 Anti-corrosion treatment

[0030] commercially available preservatives

G1

G2

G3

G4

G5

G6

G7

Spray processing temperature

80℃

75℃

95℃

80℃

80℃

90℃

75℃

95℃

drying temperature

80℃

-5℃

30℃

80℃

80℃

50℃

90℃

100℃

[0031] 3. Salt spray test

[0032] According to GB5938-86 "Corrosion Resistance Test Method of Metal Coatings and Che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com