Method for preventing corrosion inside soft packaging battery and electrode lug structure

A soft-pack battery and internal corrosion technology, which is applied in the direction of secondary batteries, structural parts, battery pack components, etc., can solve problems such as loss of water isolation, internal corrosion of soft-pack batteries, and aluminum layer rupture, so as to avoid electric shocks. Chemical reaction, effect of improving safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

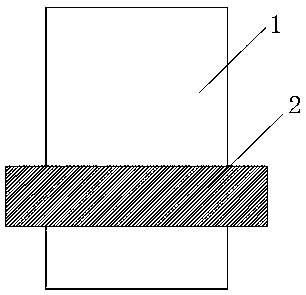

[0029] Such as figure 1 In the shown embodiment, a tab structure for preventing internal corrosion of a pouch battery includes a positive tab 1 and an aluminum-plastic film, the positive tab is rectangular, and a conductive adhesive layer 2 is provided on the surface of the positive tab near the bottom, the conductive adhesive layer Arranged along the width direction of the positive tab, the length of the conductive adhesive layer is greater than or equal to the width of the positive tab. The aluminum-plastic film includes an aluminum layer and a nylon layer on the outer surface of the aluminum layer. The conductive adhesive layer includes a basic material layer and a partial conductive adhesive layer, and the basic material layer is one or more combinations of single-layer PP, single-layer PE, multi-layer PP, and multi-layer PE. The partial conductive adhesive layer is a combination of one or more of conductive metal material powder or fiber, conductive graphite, conductive ...

Embodiment 2

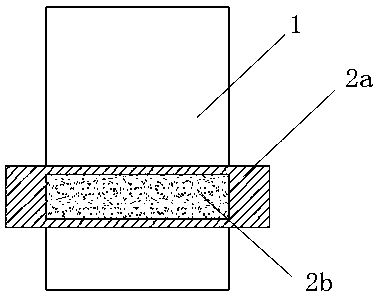

[0032] Such as figure 2 In the shown embodiment, a tab structure for preventing internal corrosion of a pouch battery includes a positive tab 1 and an aluminum-plastic film, the positive tab is rectangular, and a conductive adhesive layer 2 is provided on the surface of the positive tab near the bottom, the conductive adhesive layer Arranged along the width direction of the positive tab, the length of the conductive adhesive layer is greater than or equal to the width of the positive tab. The aluminum-plastic film includes an aluminum layer and a nylon layer located on the outer surface of the aluminum layer, and the surface of the conductive adhesive layer is bonded to the aluminum layer of the aluminum-plastic film.

[0033] The conductive adhesive layer includes a basic material layer 2a and a partial conductive adhesive layer 2b, and the basic material layer is one or more combinations of single-layer PP, single-layer PE, multi-layer PP, and multi-layer PE. The partial c...

Embodiment 3

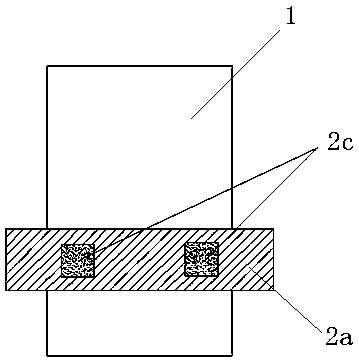

[0036] Such as image 3 In the shown embodiment, a tab structure for preventing internal corrosion of a pouch battery includes a positive tab 1 and an aluminum-plastic film, the positive tab is rectangular, and a conductive adhesive layer 2 is provided on the surface of the positive tab near the bottom, the conductive adhesive layer Arranged along the width direction of the positive tab, the length of the conductive adhesive layer is greater than or equal to the width of the positive tab. The aluminum-plastic film includes an aluminum layer and a nylon layer located on the outer surface of the aluminum layer, and the surface of the conductive adhesive layer is bonded to the aluminum layer of the aluminum-plastic film.

[0037] The conductive adhesive layer includes a basic material layer 2a and two conductive components 2c, and the basic material layer is one or more combinations of single-layer PP, single-layer PE, multi-layer PP, and multi-layer PE. The conductive component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com