Round wire multi-branch locking connector and connection method thereof

A connector and multi-branch technology, used in multi-conductor connectors, conductive connections, clamping/spring connections, etc. The small contact area of the connector and the increased contact resistance of the conductive connector can avoid electrochemical reactions, improve the reliability of the connection, and increase the contact area of the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

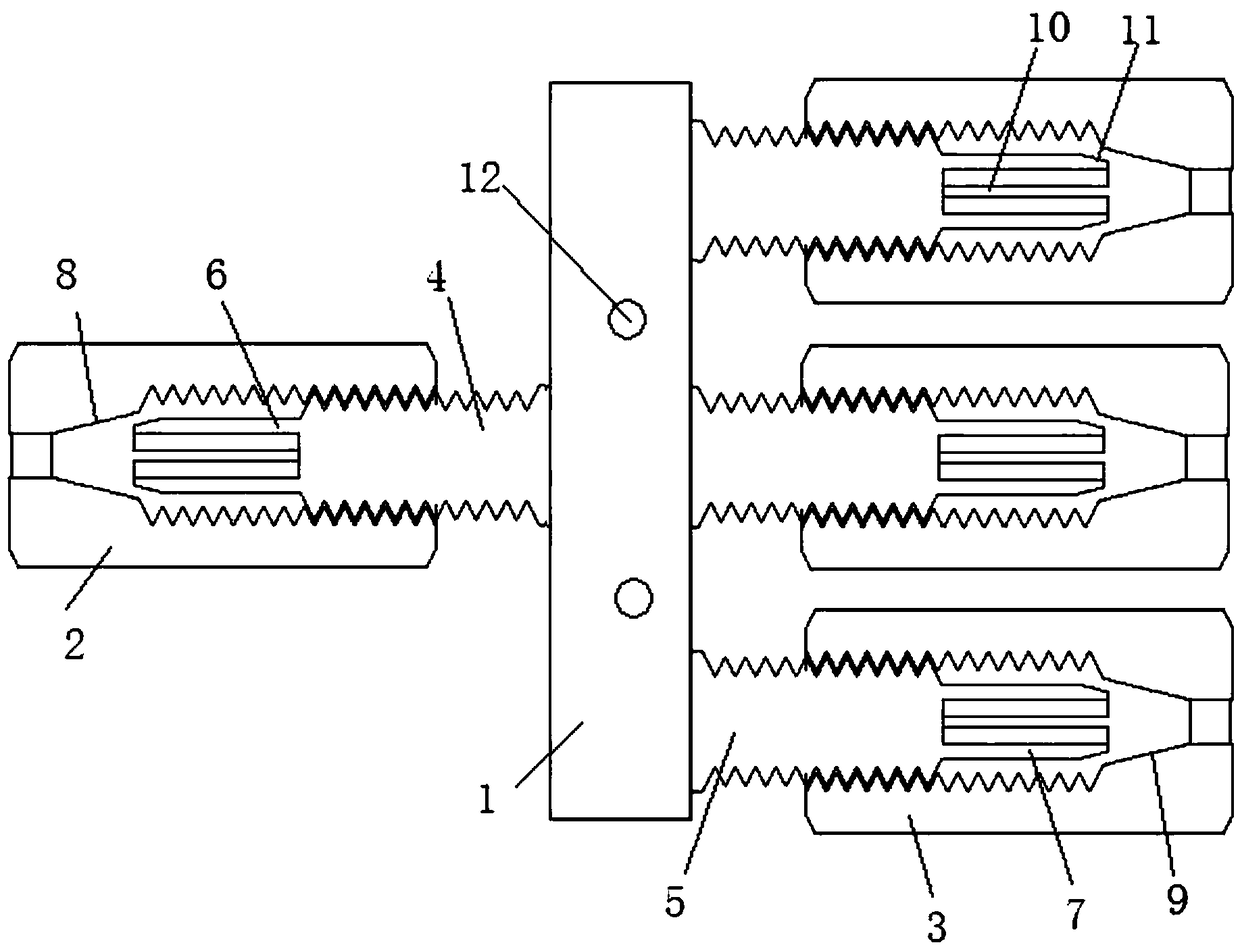

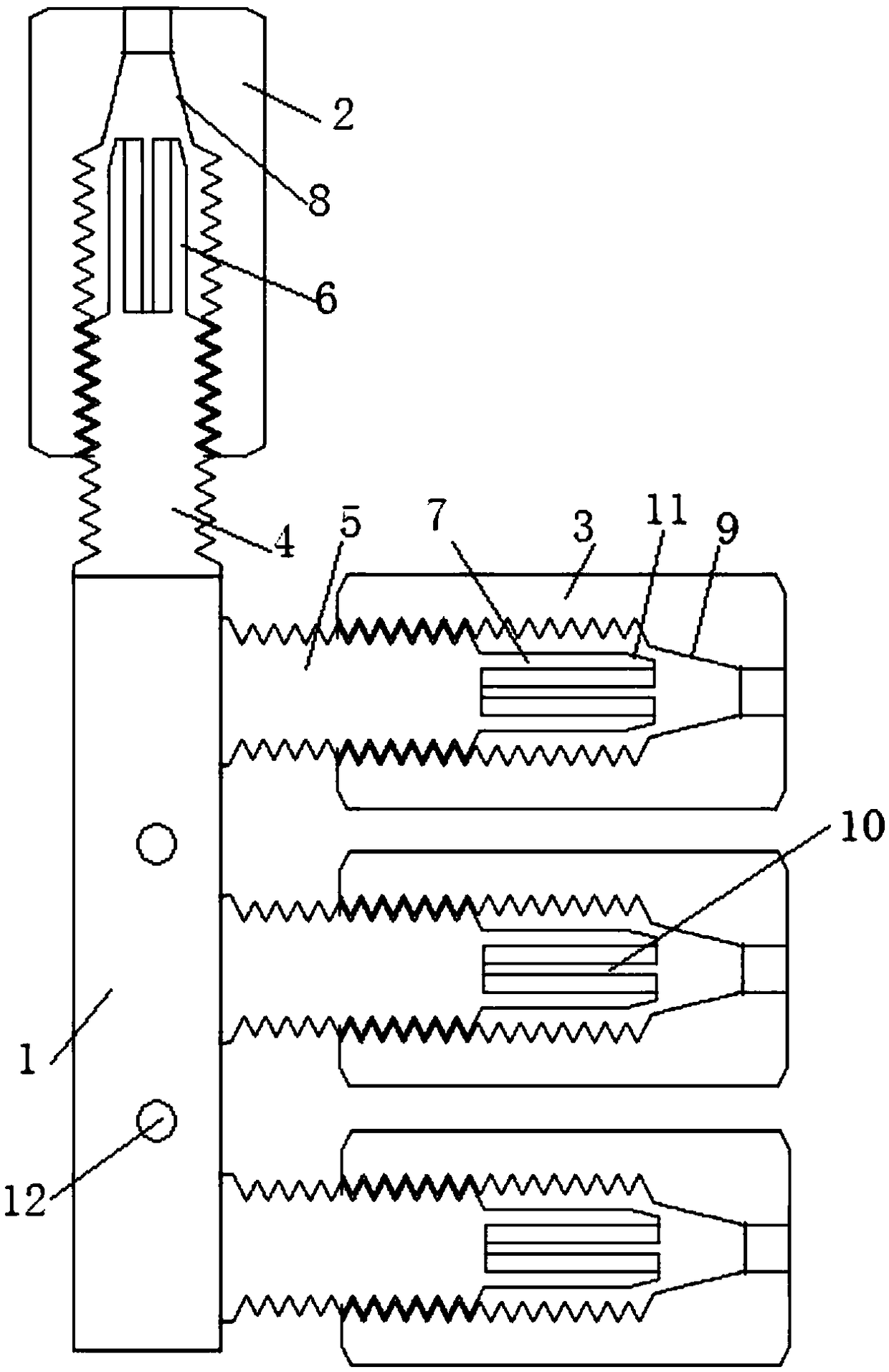

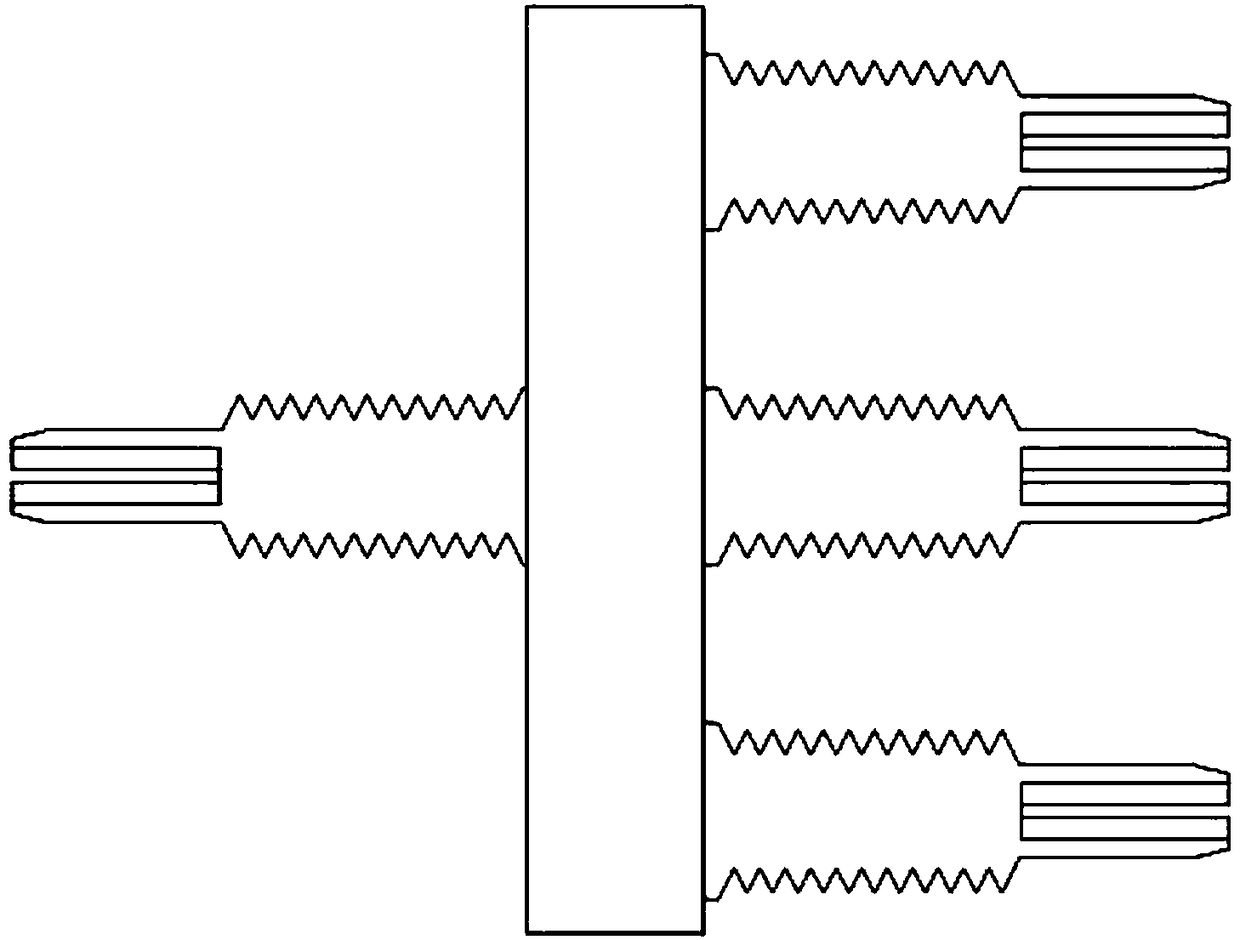

[0065] Embodiment 1: as Figure 1-Figure 9 As shown, a round wire multi-branch lock connector includes a conductive connecting body 1, an input locking nut 2 and an output locking nut 3, and the connecting body 1 is provided with an input screw part 4 and a plurality of output screw rods 5, the input screw part 4 and the end of each output screw part 5 are respectively provided with an input locking tube 6 and an output locking tube 7, and the inner holes of the outer ends of the input locking nut 2 and the output locking nut 3 are respectively provided There are input locking cone section 8 and output locking cone section 9, both input locking tube 6 and output locking tube 7 are provided with U-shaped opening 10, input locking nut 2 and output locking nut 3 are respectively connected to On the input screw part 4 and the output screw part 5 , the input locking cone segment 8 and the output locking cone segment 9 are squeezed on the input locking tube 6 and the output locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com