An aircraft climate test connecting device and its parameter optimization method

A climate test and connecting device technology, which is applied in the direction of aircraft component testing, connecting components, measuring devices, etc., to achieve good heat preservation, ensure integrity, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The main purpose of embodiment 1 is to set forth the structural design of the present invention under concrete parameters, and concrete technical scheme is as follows:

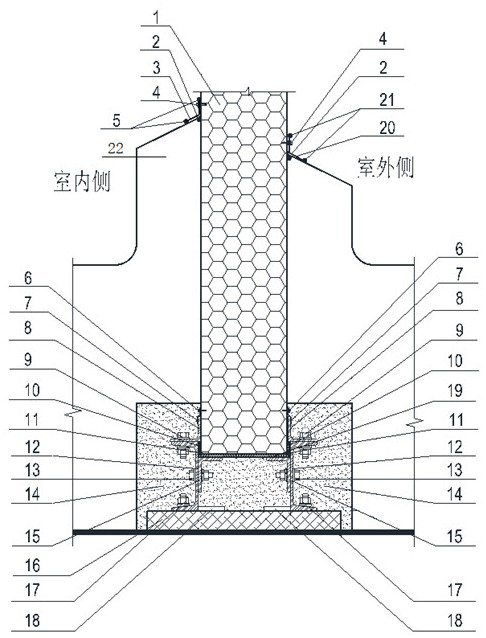

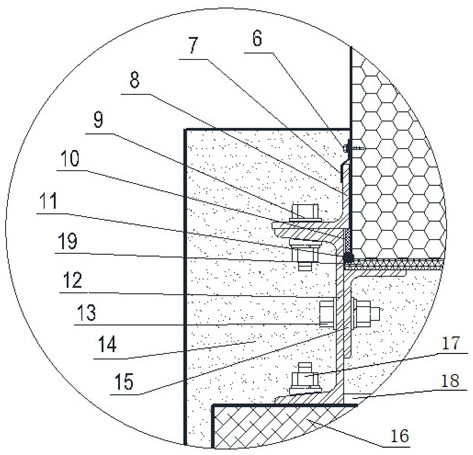

[0052] see figure 2 , 3 , an aircraft climate test connection device designed by the present invention, comprising a base arranged in the floor, and a thermal insulation wall plate 1 vertically inserted in the base;

[0053] Taking the section perpendicular to the plane where the thermal insulation wallboard 1 is located as the observation plane, the base includes anti-corrosion wood pads horizontally set on the floor surface -0.62m plane with length×width×thickness=450mm×240mm×50mm 16. A 16a hot-dip galvanized full-length channel steel 12 is respectively arranged on both sides of the top surface of the anticorrosive wood spacer 16 at a distance of 120mm from the edge; The lower side flange stands on the top surface of the anti-corrosion wood pad 16, and the anti-corrosion wood pad 16 is connected wi...

Embodiment 2

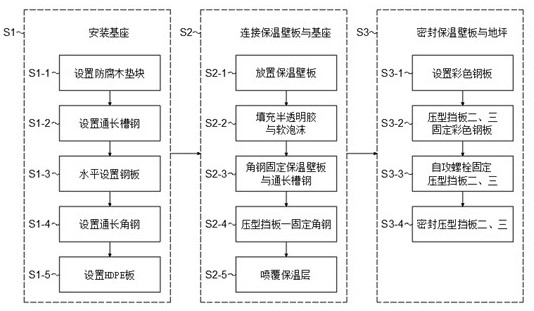

[0066] The narration basis of embodiment 2 is the scheme recorded in embodiment 1, aiming to illustrate the parameter optimization method of the connection device described under specific parameters, see figure 1 ,Specific steps are as follows:

[0067] S1. Install the base

[0068] S1-1. Taking the cross-section perpendicular to the plane where the thermal insulation wallboard 1 is located as the observation plane, horizontally set the anti-corrosion wood block 16 of length × width × thickness = 450mm × 240mm × 50mm on the floor surface -0.62m plane, The plane formed by the long thick sides of the anti-corrosion wood block 16 is parallel to the observation plane;

[0069] S1-2, a 16a hot-dip galvanized full-length channel steel 12 is respectively arranged at both sides of the top surface of the anti-corrosion wood pad 16 at 120 mm from the edge, and the anti-corrosion wood pad 16 is connected to each full-length channel steel 12 The adjacent flanges are all connected by bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com