Oil-resistant anti-rust paint and preparation method thereof

An anti-rust coating and oil-resistant technology, used in anti-corrosion coatings, conductive coatings, polyurea/polyurethane coatings, etc., can solve the problems of low anti-static performance, oil resistance and anti-corrosion performance, and achieve good anti-rust effect and good static electricity conduction. good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

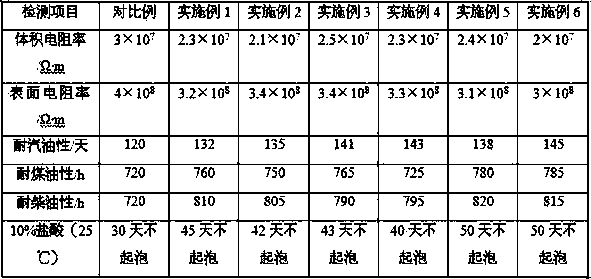

Examples

Embodiment 1

[0016] This embodiment provides an oil-resistant and anti-rust coating, which is prepared in parts by mass from the following raw materials: 17 parts of trimethylolpropane, 26 parts of toluene diisocyanate, 0.2 part of dibutyl hydroxytoluene, 0.1 part of organic bentonite, 2 parts of turpentine 0.1 part of paraffin, 40 parts of xylene, 6 parts of high chlorinated polyethylene resin, 2.5 parts of titanium dioxide, 2.5 parts of mica powder, 1 part of talcum powder, 0.1 part of diphenylguanidine, and 6 parts of banana water.

[0017] A kind of preparation steps of oil-resistant rust-proof coating is as follows:

[0018] (1) Mix trimethylolpropane, toluene diisocyanate, dibutyl hydroxytoluene, organic bentonite, turpentine, paraffin and xylene to obtain mixture A;

[0019] (2) Mix high-chlorinated polyethylene resin, titanium dioxide, mica powder, talcum powder, diphenylguanidine and banana water evenly to obtain mixture B;

[0020] (3) Mix mixture A and mixture B, place it at 10...

Embodiment 2

[0022] This embodiment provides an oil-resistant and anti-rust coating, which is prepared in parts by mass from the following raw materials: 18 parts of trimethylolpropane, 27 parts of toluene diisocyanate, 0.3 part of dibutyl hydroxytoluene, 0.13 part of organic bentonite, 2.5 parts of turpentine 0.11 parts of paraffin, 42 parts of xylene, 7 parts of high-chlorinated polyethylene resin, 2.7 parts of titanium dioxide, 2.8 parts of mica powder, 1.5 parts of talcum powder, 0.13 parts of diphenylguanidine, and 7 parts of banana water.

[0023] A kind of preparation steps of oil-resistant rust-proof coating is as follows:

[0024] (1) Mix trimethylolpropane, toluene diisocyanate, dibutyl hydroxytoluene, organic bentonite, turpentine, paraffin and xylene to obtain mixture A;

[0025] (2) Mix high-chlorinated polyethylene resin, titanium dioxide, mica powder, talcum powder, diphenylguanidine and banana water evenly to obtain mixture B;

[0026] (3) Mix mixture A and mixture B, plac...

Embodiment 3

[0028] This embodiment provides an oil-resistant and anti-rust coating, which is prepared in parts by mass from the following raw materials: 28 parts of trimethylolpropane, 42 parts of toluene diisocyanate, 1.2 parts of dibutyl hydroxytoluene, 0.3 parts of organic bentonite, 5 parts of turpentine 0.2 parts of paraffin, 50 parts of xylene, 12 parts of high chlorinated polyethylene resin, 5 parts of titanium dioxide, 5 parts of mica powder, 4 parts of talcum powder, 0.22 parts of diphenylguanidine, and 13 parts of banana water.

[0029] A kind of preparation steps of oil-resistant rust-proof coating is as follows:

[0030] (1) Mix trimethylolpropane, toluene diisocyanate, dibutyl hydroxytoluene, organic bentonite, turpentine, paraffin and xylene to obtain mixture A;

[0031] (2) Mix high-chlorinated polyethylene resin, titanium dioxide, mica powder, talcum powder, diphenylguanidine and banana water evenly to obtain mixture B;

[0032] (3) Mix mixture A and mixture B, place it a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com