Pipe for 105ksi titanium alloy petroleum drill rod and manufacturing method

A 105ksi, oil drill pipe technology, applied in the field of oil and gas industry drilling, can solve the problems of high cost, difficult processing and manufacturing, 105ksi grade drill pipe body mechanical properties and heat treatment process are not clear, etc., to achieve simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

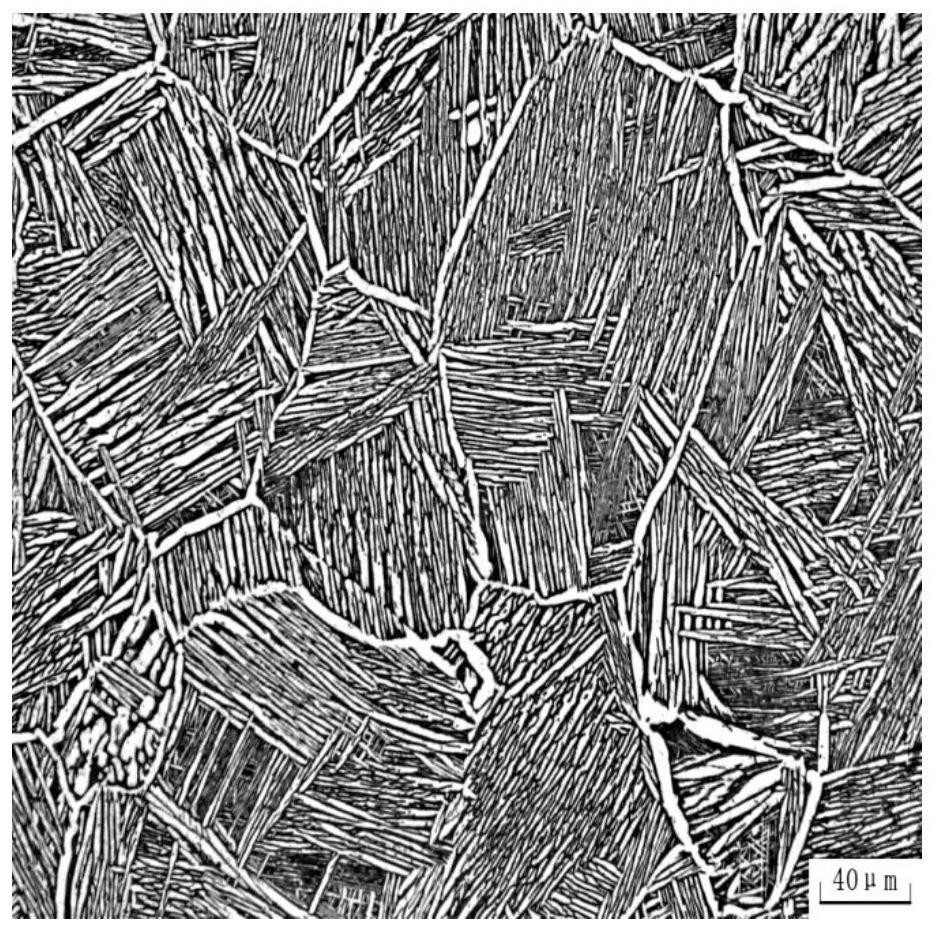

Image

Examples

Embodiment 1

[0034] The titanium alloy oil drill pipe body provided by a company is used, its specific composition is Al: 5.1%, Mo: 0.8%, V: 3.2%, Zr: 1.7%, the rest is Ti, the unit is mass percentage, and its heat treatment process operation Proceed as follows.

[0035] Step 1, preparing materials according to the ratio of ingredients to be smelted and cast into a round billet;

[0036] Step 2: Heating the ingot to 1000°C and holding it for 1 hour to extrude, the extrusion ratio is greater than 9, and the extrusion speed is 17mm / s.

[0037] Step 3, rolling the above-mentioned extruded titanium alloy oil pipe at a rolling temperature of 500°C.

[0038] Step 4, coating Cr on the surface of the titanium alloy oil drill pipe body 2 o 3 protective coating.

[0039] Step 5, solid solution treatment is carried out on the pipe coated with the protective coating; the titanium alloy oil drill pipe body is sent into a heating furnace heated to 1000°C, kept for 60 minutes, and the pipe is air-coo...

Embodiment 2

[0043] Step 1, according to the mass percentage, take 4.9% Al, 0.7% Mo, 3.0% V and 1.5% Zr, and the rest is Ti, and make an ingot;

[0044] Step 2, heating up the ingot, the heating temperature is 980°C, and extrusion is carried out after holding the heat for 1 hour. During extrusion, the extrusion ratio is greater than 9, and the extrusion speed is 17mm / s;

[0045] Step 3, rolling the extruded billet at a rolling temperature of 450°C;

[0046] Step 4, coating the surface of the rolled pipe with a protective coating Cr 2 o 3 ;

[0047] Step 5, carry out solid solution treatment on the pipe coated with protective coating; raise the temperature of the pipe to 980°C, keep it warm for 45 minutes, and air cool the pipe to room temperature to complete the solution treatment;

[0048] Step 6: Perform aging treatment on the solution-treated pipe; heat the solution-treated pipe to 550° C., keep it warm for 5 hours, and air-cool to room temperature to complete the manufacture.

Embodiment 3

[0050] Step 1, according to the mass percentage, take 5.3% Al, 0.9% Mo, 3.3% V and 2% Zr, and the rest is Ti, and make an ingot;

[0051]Step 2, heating up the ingot, the heating temperature is 1050°C, and extruding after holding the heat for 1 hour, during extrusion, the extrusion ratio is greater than 9, and the extrusion speed is 17mm / s;

[0052] Step 3, rolling the extruded billet at a rolling temperature of 550°C;

[0053] Step 4, coating the surface of the rolled pipe with a protective coating Cr 2 o 3 ;

[0054] Step 5, carry out solid solution treatment on the pipe coated with the protective coating; heat the pipe to 1050°C, keep it warm for 60 minutes, air cool the pipe to room temperature, and complete the solid solution treatment;

[0055] Step 6: Perform aging treatment on the solution-treated pipe; raise the temperature of the solution-treated pipe to 650° C., keep it warm for 7 hours, and air-cool to room temperature to complete the manufacture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com