Shaped steel excellent in fire resistance and producing method therefore

A type of steel and cast steel technology, applied in the field of preparation of the type steel, can solve the problems of increasing strength and yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] Embodiments of the present invention are described below. However, the conditions described in these examples are merely descriptive, and the present invention is not limited to these conditions. The present invention can be carried out under other various conditions without departing from the gist of the present invention in order to achieve the object of the present invention.

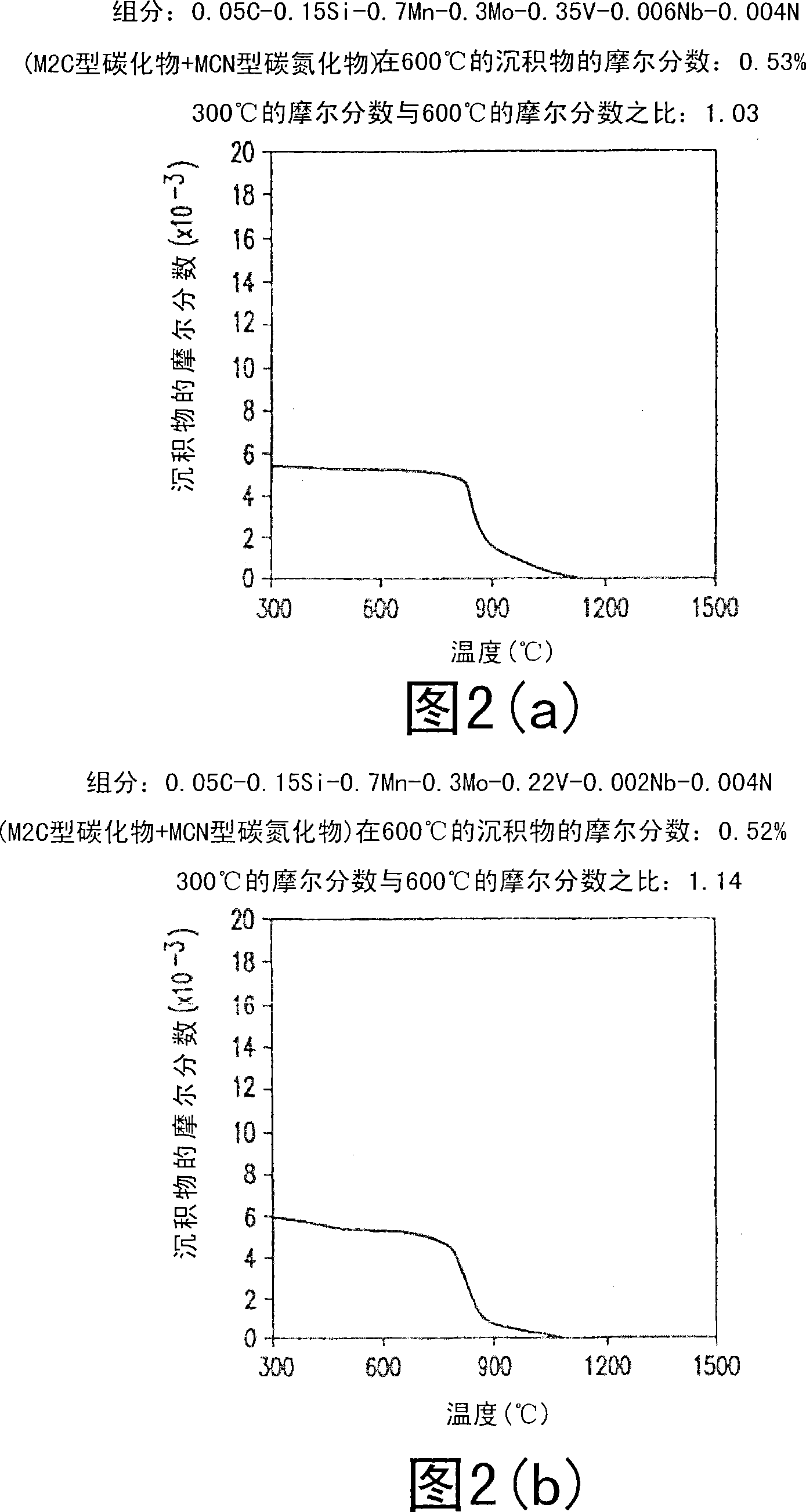

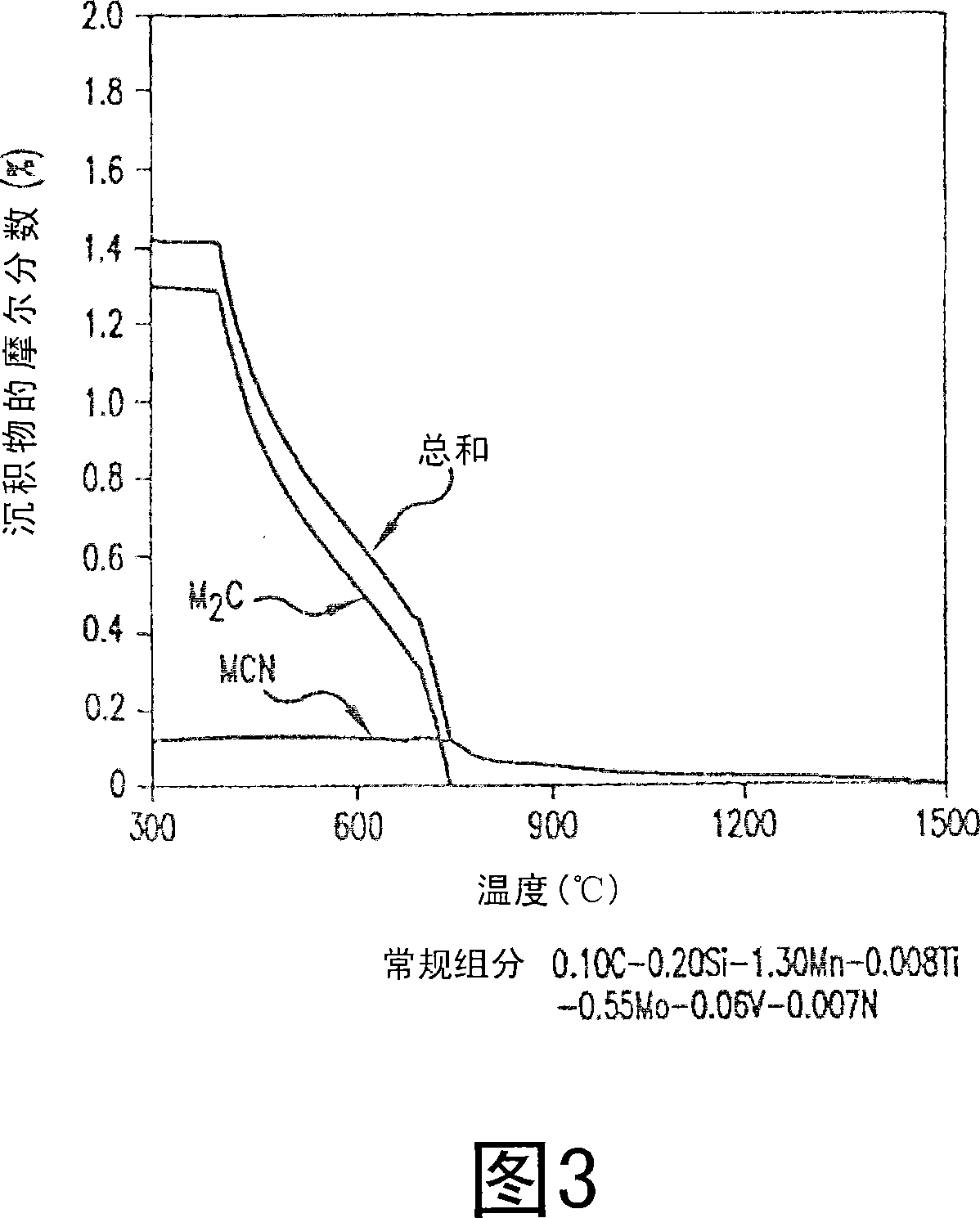

[0103] The steel ingots and billets used in these examples, having the components / compositions shown in Table 1 and having predetermined mole fractions of deposits by "Thermo-Calc" equilibrium calculations at 600°C and 300°C, were used in the smelting process. Melting in a steel furnace and pouring ingots and billets with a thickness of about 240-300mm in a continuous casting process. In Table 1, "tr" means "undetectable" or "inevitable impurity".

[0104] The conditions of Examples "a-g" of the comparative steel are not within the scope of the present invention. The conditions of the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic limit | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com