Sample clamping device for thin plate impact performance detection and test method

A technology of impact performance and impact test, which is used in measuring devices, using repetitive force/pulse force to test the strength and strength characteristics of materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Using this device to measure the sample of 1300MPa grade material in the undeformed state, respectively 20 ℃, 10 ℃, 0 ℃, -10 ℃, -20 ℃, -30 ℃, -40 ℃, -50 ℃, -60 ℃, Impact test under 10 temperature conditions at -70°C. A non-standard sample of 55×1.2×10 mm is used, and the depth of the V-shaped notch is 2 mm. The selected testing machine is a Charpy V-notch impact testing machine with a blade arc radius of 2mm and an impact energy of 100J.

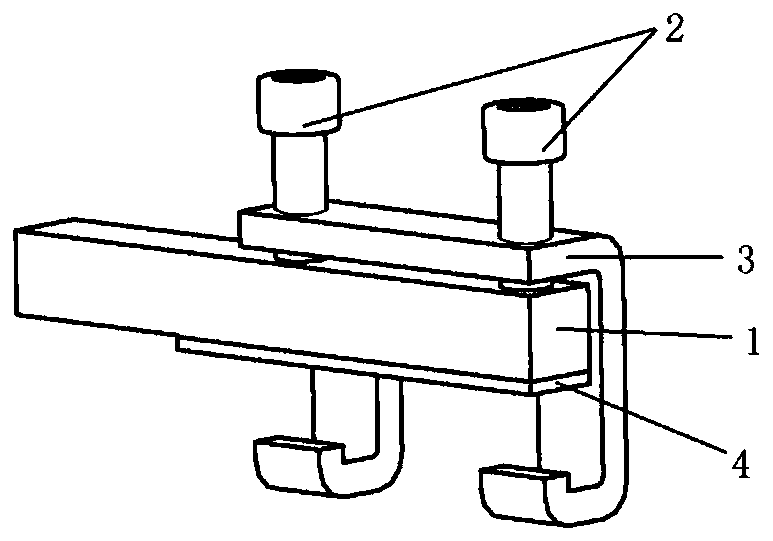

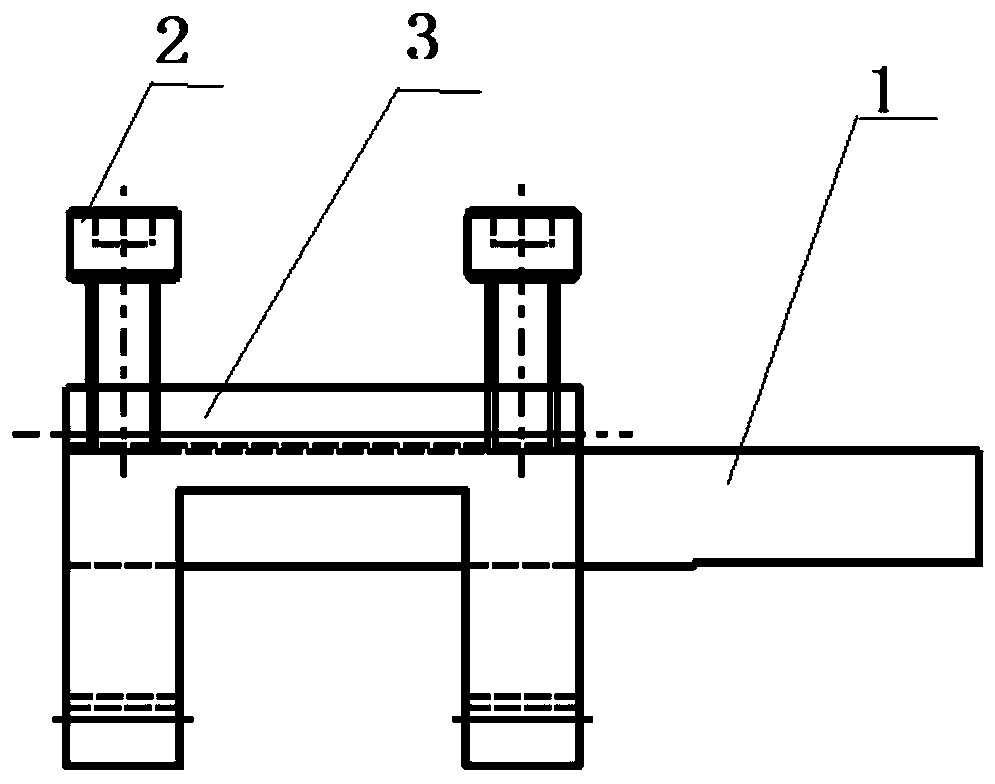

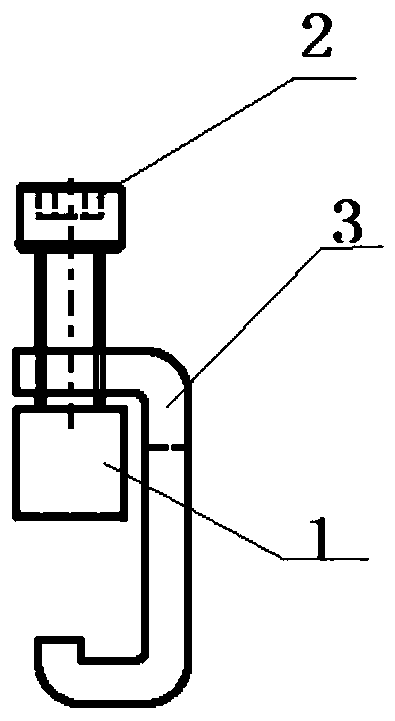

[0035] A sample clamping device for testing the impact performance of thin plates, including an impact test bench beam 5, an impact test bench 6, and a jaw support block 1, fastening bolts 2, clamping hooks 3, gaskets 4, and samples Concave platform 7, the jaw support block 1 is a long steel plate, a sample concave platform 7 is arranged on one side of the steel plate, the shape of the gasket 4 matches the sample 8, and the end of the clamping hook 3 is a connecting The body steel plate is provided with a bolt hole, and one end is p...

Embodiment 2

[0048] Using this device to measure the sample of 1300MPa grade material in the pre-stretched state of 3%, respectively 20 ℃, 10 ℃, 0 ℃, -10 ℃, -20 ℃, -30 ℃, -40 ℃, -50 ℃, Impact test under 10 temperature conditions of -60°C and -70°C. A non-standard sample of 55×1.2×10 mm is used, and the depth of the V-shaped notch is 2 mm. The testing machine used is a Charpy V-notch impact testing machine with a blade arc radius of R2 and an impact energy of 50J.

[0049]A sample clamping device for testing the impact performance of thin plates, including an impact test bench beam 5, an impact test bench 6, and a jaw support block 1, fastening bolts 2, clamping hooks 3, gaskets 4, and samples Concave platform 7, the jaw support block 1 is a long steel plate, a sample concave platform 7 is arranged on one side of the steel plate, the shape of the gasket 4 matches the sample 8, and the end of the clamping hook 3 is a connecting The body steel plate is provided with a bolt hole, and one end...

Embodiment 3

[0062] Use this device to measure the sample of 1300MPa grade material in the pre-stretched state of 6%, respectively at 20°C, 10°C, 0°C, -10°C, -20°C, -30°C, -40°C, -50°C, - Impact test under 10 temperature conditions of 60°C and -70°C. A non-standard sample of 55×1.2×10 mm is used, and the depth of the V-shaped notch is 2 mm. The testing machine used is a Charpy V-notch impact testing machine with a blade arc radius of R2 and an impact energy of 30J.

[0063] A sample clamping device for testing the impact performance of thin plates, including an impact test bench beam 5, an impact test bench 6, and a jaw support block 1, fastening bolts 2, clamping hooks 3, gaskets 4, and samples Concave platform 7, the jaw support block 1 is a long steel plate, a sample concave platform 7 is arranged on one side of the steel plate, the shape of the gasket 4 matches the sample 8, and the end of the clamping hook 3 is a connecting The body steel plate is provided with a bolt hole, and one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com