Metal material surface modified treatment method

A surface modification and treatment method technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inconvenient replacement, poor heating effect, warping, etc., to improve mechanical properties, high hardness and wear resistance, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

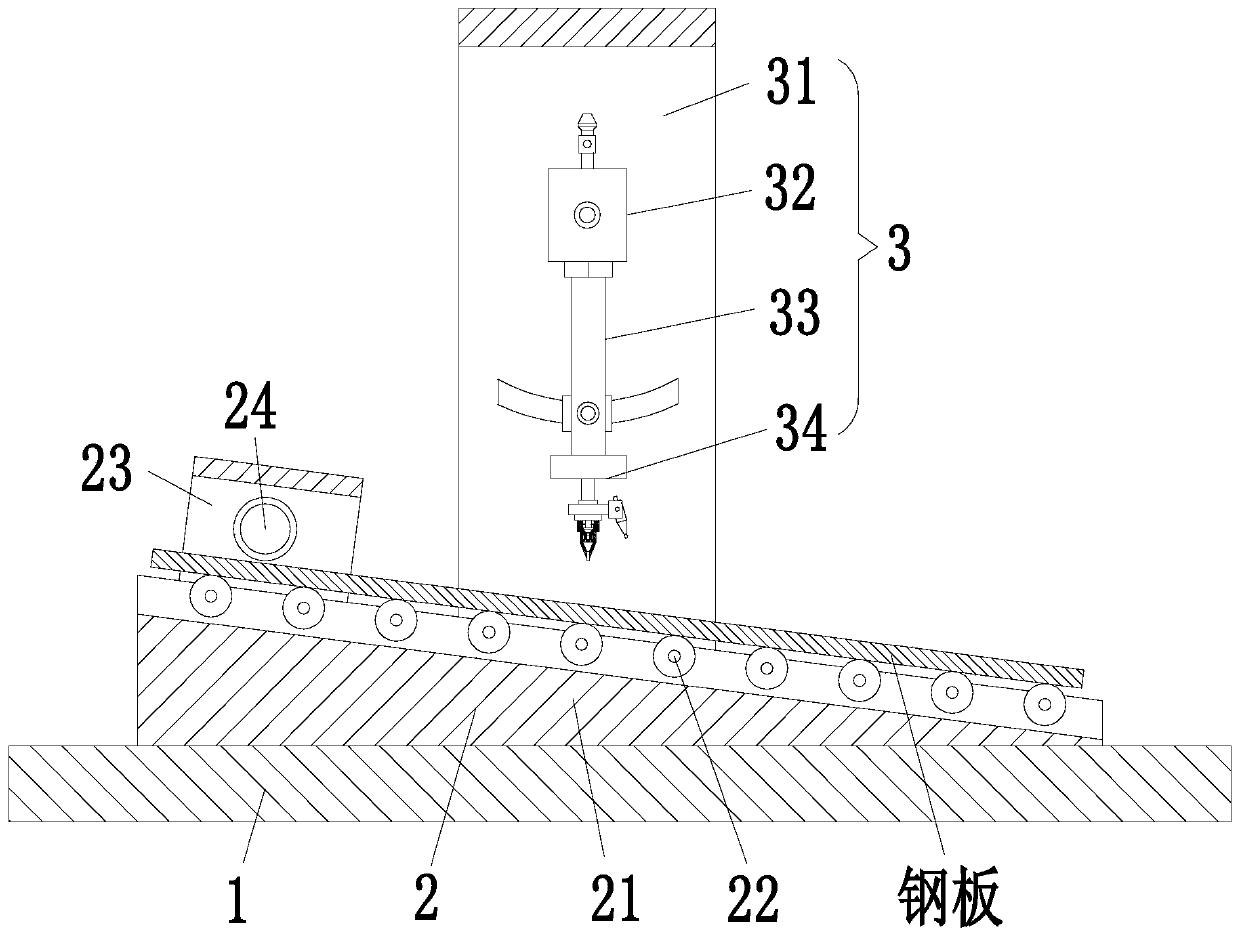

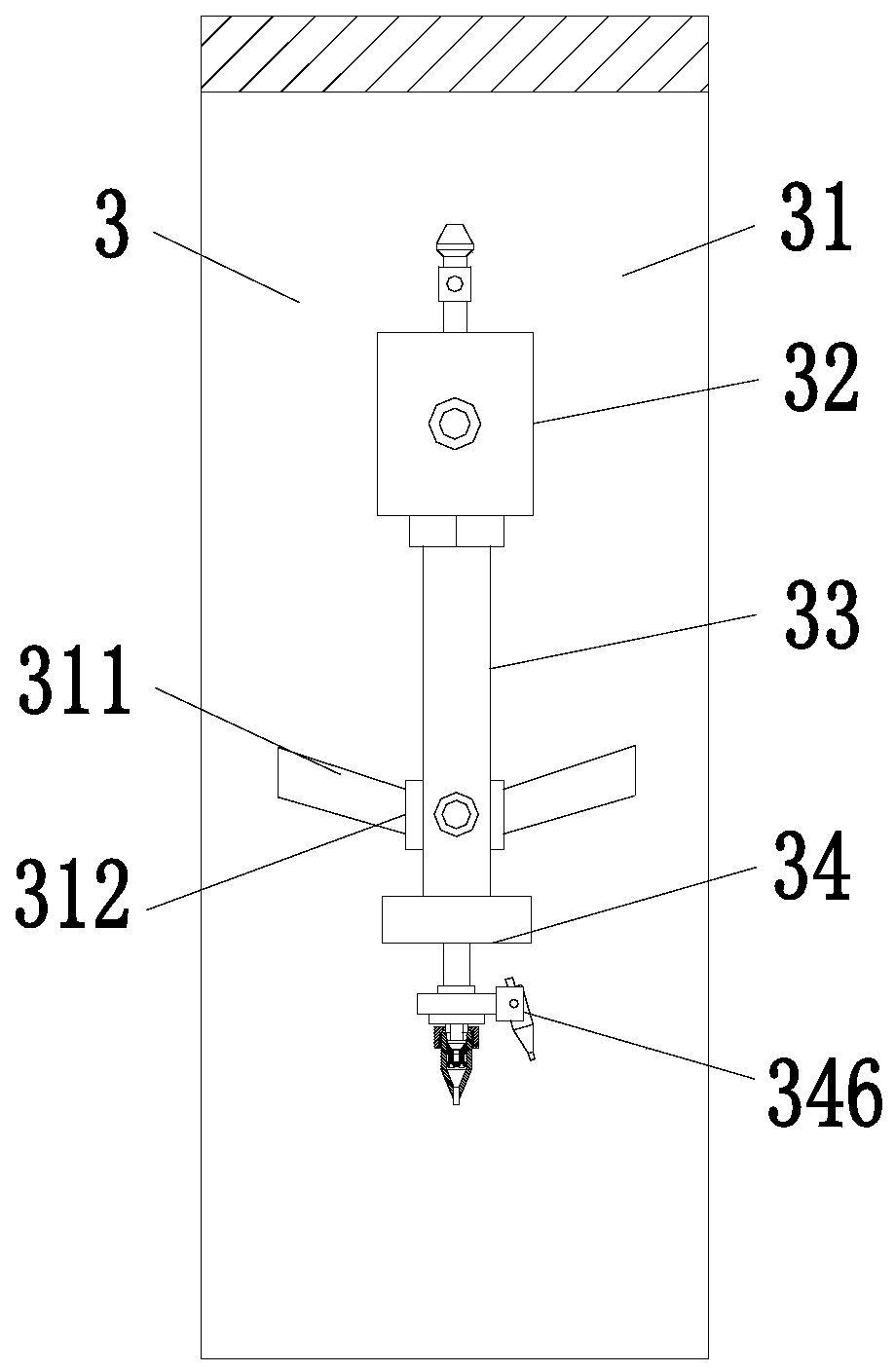

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

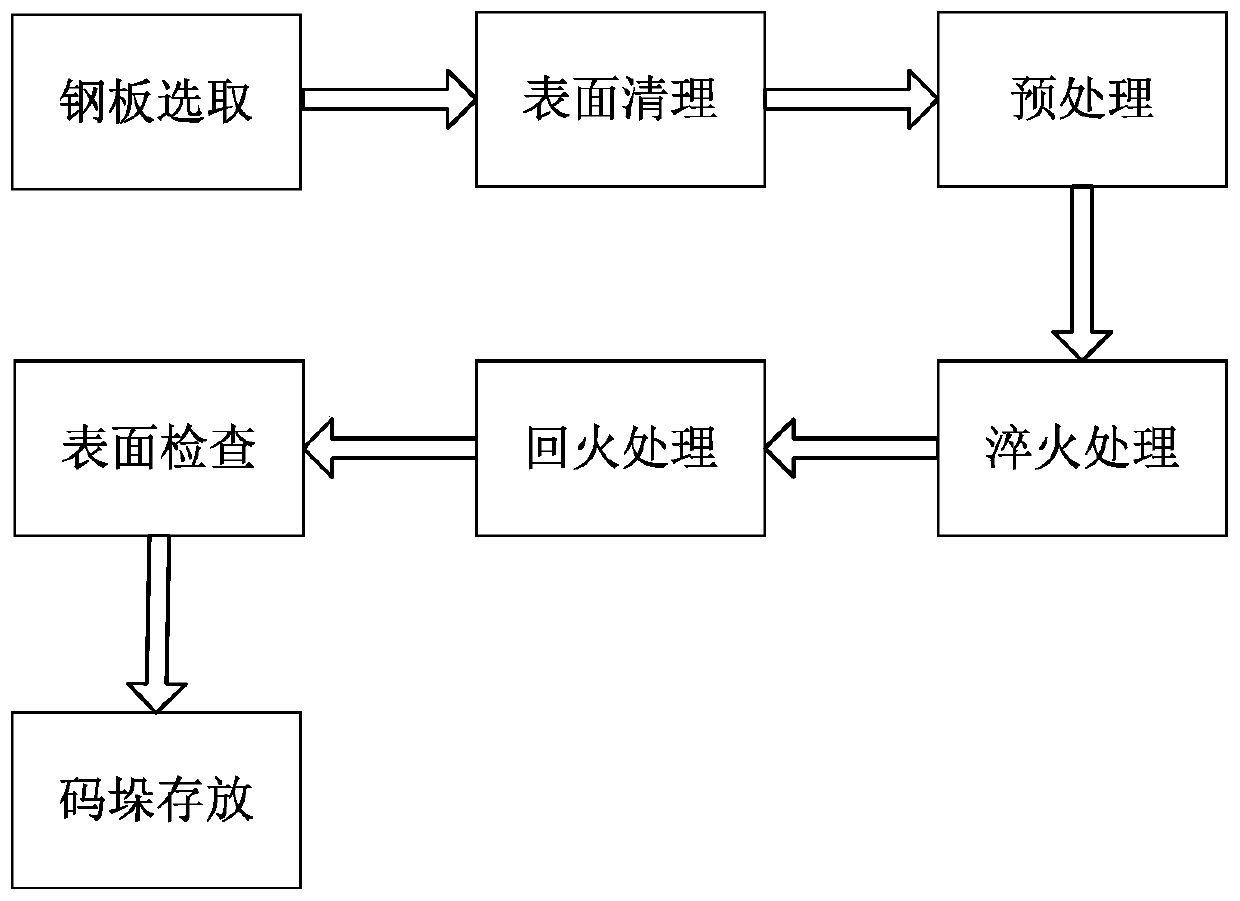

[0036] Such as Figure 1 to Figure 5 Shown, a kind of metal material surface modification processing method comprises the following steps:

[0037] S1. Selection of steel plate: choose medium carbon steel plate or high carbon steel plate of appropriate size according to the needs of use;

[0038] S2, surface cleaning: manual cleaning and removal of impurities such as scale, burrs, and rust on the surface of the steel plate selected in step S1;

[0039] S3. Pretreatment: pretreat the steel plate by one or more methods of normalizing, annealing, quenching and tempering treatment and spheroidizing annealing, so as to meet the needs of mechanical processing and prepare for the final heat treatment;

[0040] S4, quenching treatment: put the steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com