Steel and method for manufacturing same

A manufacturing method and microstructure technology, applied in the field of structural steel, can solve the problems of high alloy cost and manufacturing cost, and achieve the effect of excellent tensile performance and excellent economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

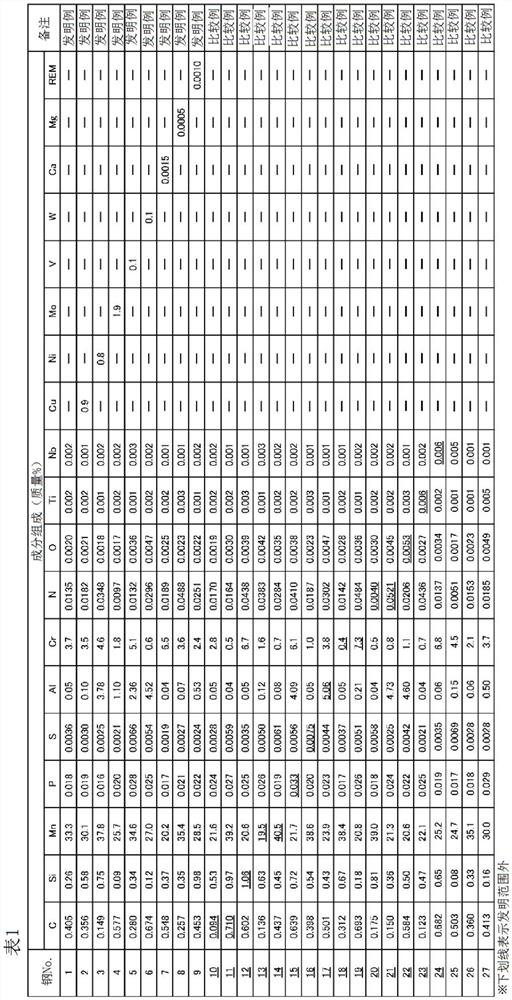

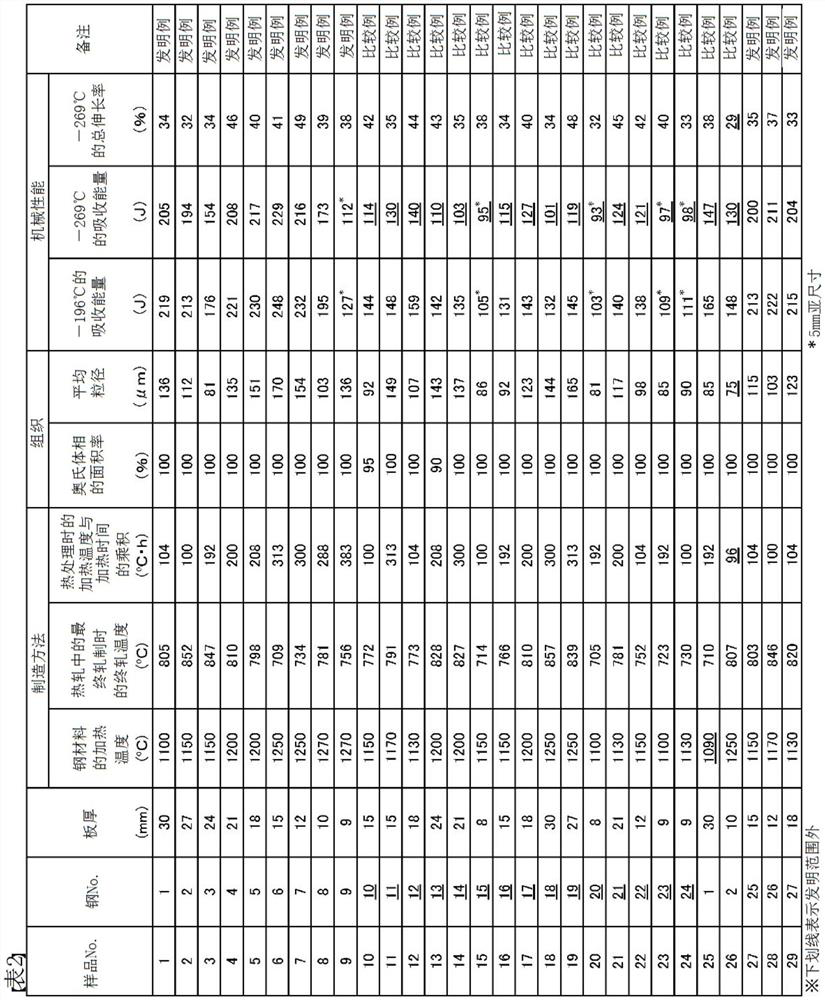

[0099] Hereinafter, the present invention will be described in detail through examples. In addition, this invention is not limited to the following examples.

[0100] Steel billets (billet materials) having the composition shown in Table 1 were produced by a converter-ladle refining-continuous casting method. Next, under the conditions shown in Table 2, the obtained steel slab was hot-rolled into a steel plate with a thickness of 6 to 30 mm. Here, for each sample, the heating temperature at the time of reheating in the heat treatment was set to the same temperature as the heating temperature of the steel slab.

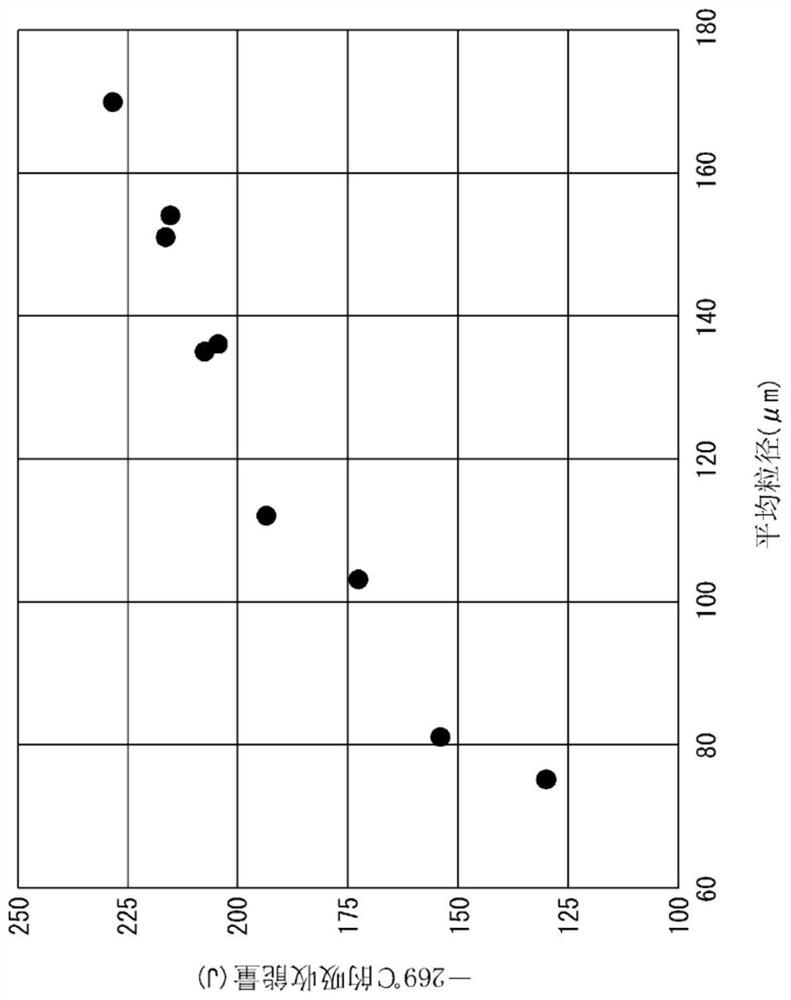

[0101] For the obtained steel sheets, microstructure evaluation and mechanical property evaluation of cryogenic toughness and tensile properties were carried out in the following manner.

[0102] In Table 2, "finish rolling temperature at the time of final rolling" indicates the final rolling finish temperature.

[0103] (1) Organization evaluation

[0104] ・The area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com