Pipeline steel Charpy specimen fracture separation degree grading method

A technology of impact sample and degree of separation, applied in the direction of analyzing materials, strength properties, measuring devices, etc., can solve the problems of difficulty in determining parameters, infeasible inspection, and large differences in parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

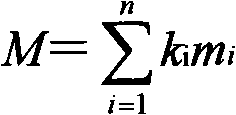

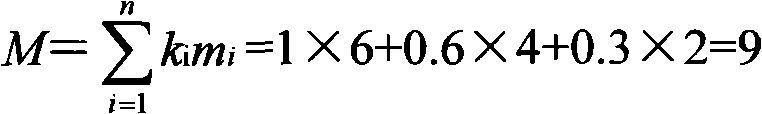

[0021] During the manufacturing inspection of steel plates and steel pipes for oil and gas pipelines, observe the fracture of the samples after the Charpy impact toughness test, measure the length of the separation cracks and sort them. The score m of separation cracks of different lengths and the weight coefficient k of each separation crack are obtained by looking up the table. Add the product of the score m of each separation crack and the weight coefficient k to obtain the total score M value. According to the total score M, look up the table to obtain the classification of the fracture separation degree of each impact sample. If the fracture separation coefficient of the sample exceeds a certain level (determined by the specific engineering technical conditions), a series of temperature impact toughness tests are carried out, and the parameters of the rising platform are calculated. The fracture separation proposes control measures.

[0022] 10mm×10mm standard size impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com